High-frequency vibrating screen and spiral chute combined mineral separation process for separating zircon-titanium ore

A technology of high-frequency vibrating screen and spiral chute, which is applied in the direction of filter screen, solid separation, wet separation, etc., can solve the problems of low grade of ilmenite, difficulty in shaking table separation, complex particle size composition, etc., and achieve the separation effect Good, good beneficiation effect, easy grading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

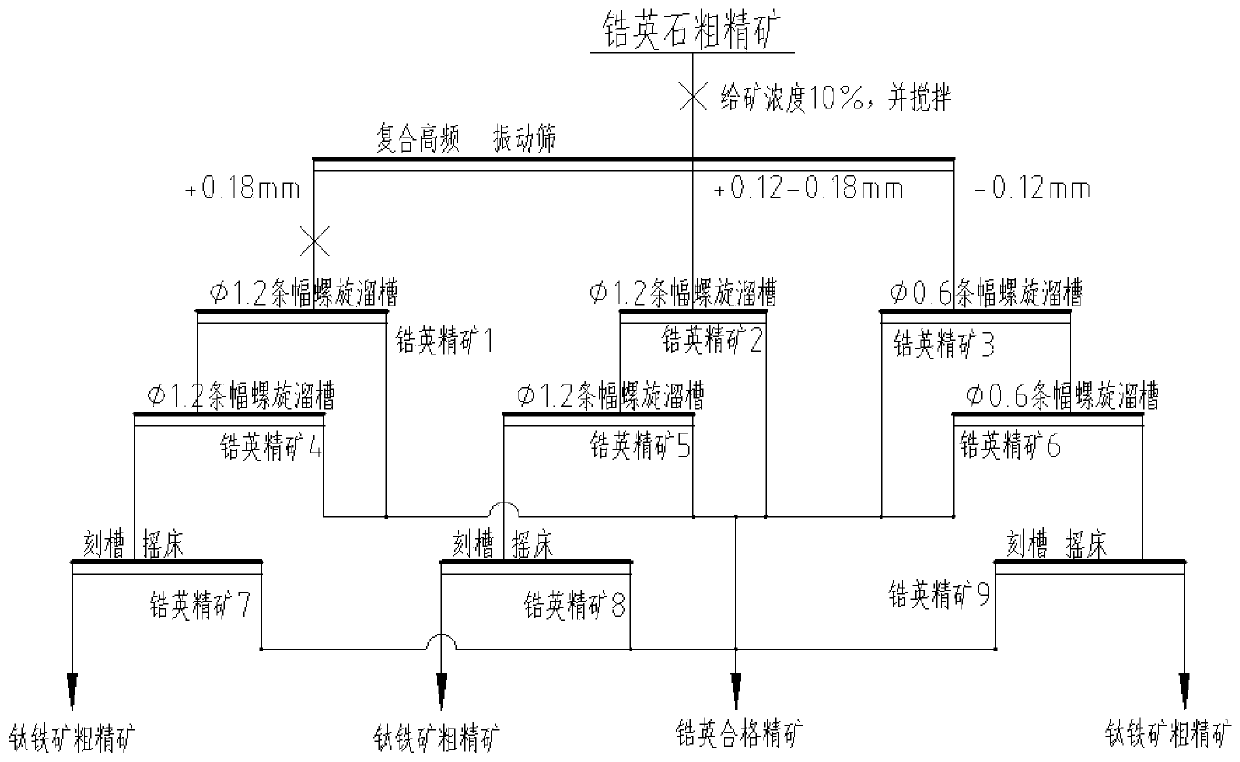

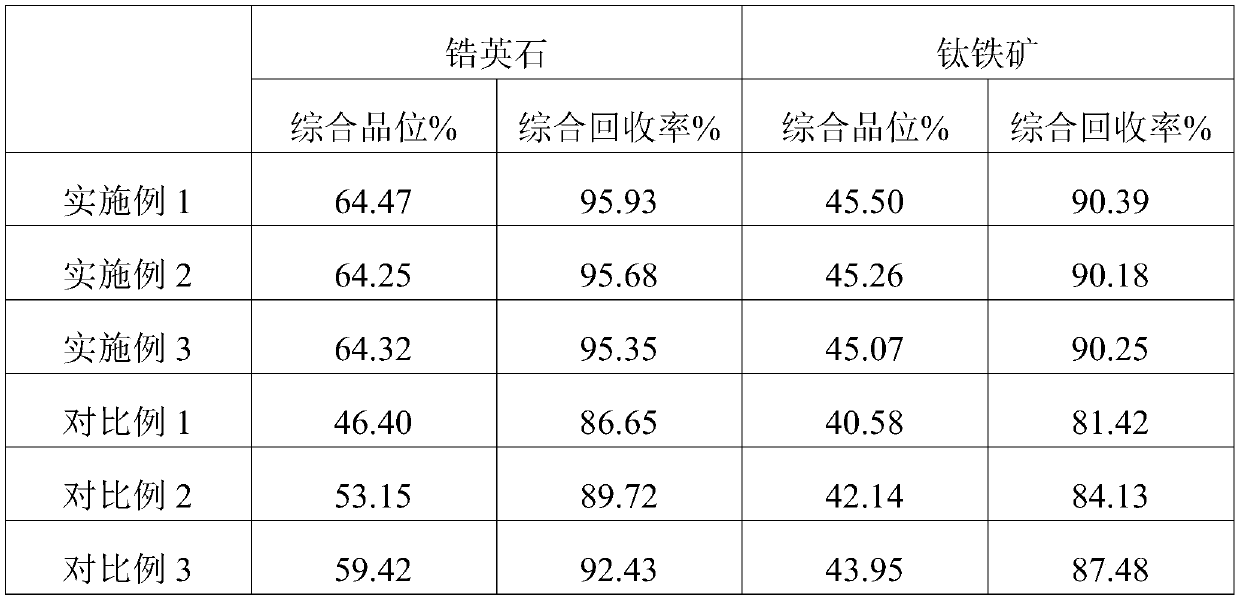

[0026] The raw material is the seashore placer of Yimeizhi mine in Australia. The raw ore is subjected to magnetic separation to obtain zircon rough concentrate. The raw ore contains 45.58% ZrO2 and 5.28% TiO2. The particle size distribution of zircon is extremely uneven, with +0.18mm accounting for 23.85%, -0.18mm+0.12mm accounting for 34.26%, and -0.12mm accounting for 41.89%. The distribution is extremely uneven, and the method of pre-grading - rough selection in spiral chute - sweeping in spiral chute - sweeping in shaking table is adopted. Such as figure 1 The process flow, the specific process parameters are:

[0027] (1) High frequency sieve classification

[0028] Zircon coarse concentrate is obtained after the ore is magnetically separated, and ZrO in zircon 2 % content 45.58%, TiO 2 % content 5.28%. The high frequency sieve is 6m 2 The double-layer screen, the length of the single-layer screen is 3 meters, the upper screen uses 0.20mm mesh, and the lower screen...

Embodiment 2

[0041] The difference between this embodiment and Example 1 is that in step (1), the screening feed concentration is 5%, and the processing capacity is 1 ton / hour; in step (2), the feed concentration of three grain grade products is 20% respectively. %, the amount of ore feeding is 2 tons / hour (dry ore amount); in step (4), the stroke of the shaking table is 0.8cm, and the number of strokes is 300 times / min.

Embodiment 3

[0043] The difference between the present embodiment and embodiment 1 is that in step (3), the ore feeding concentration of three particle grade products is respectively 20%, and the ore feeding amount is 2 tons / hour (dry ore amount); in step (4), The stroke of the shaker is 1.2 cm, and the stroke frequency is 500 times / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com