Application method of 2-ethyl-2-hexenealdoxime in mineral flotation

An application method, mineral flotation technology, applied in flotation, solid separation, etc., can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

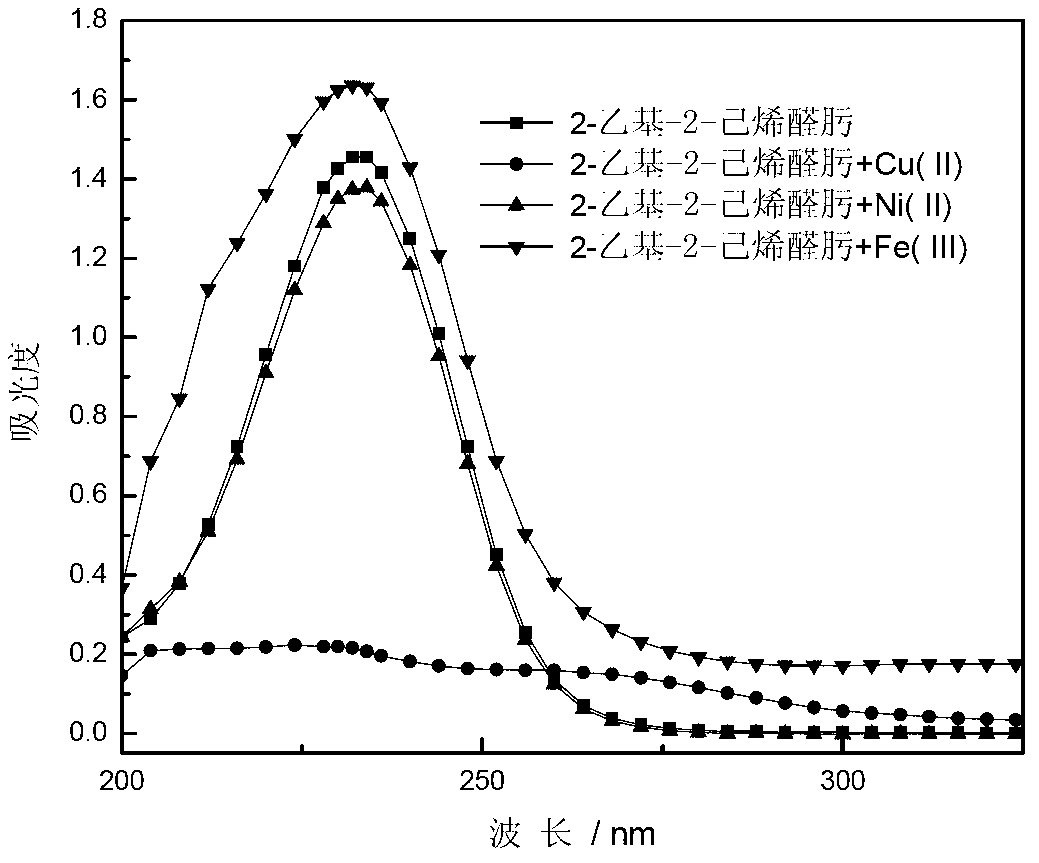

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

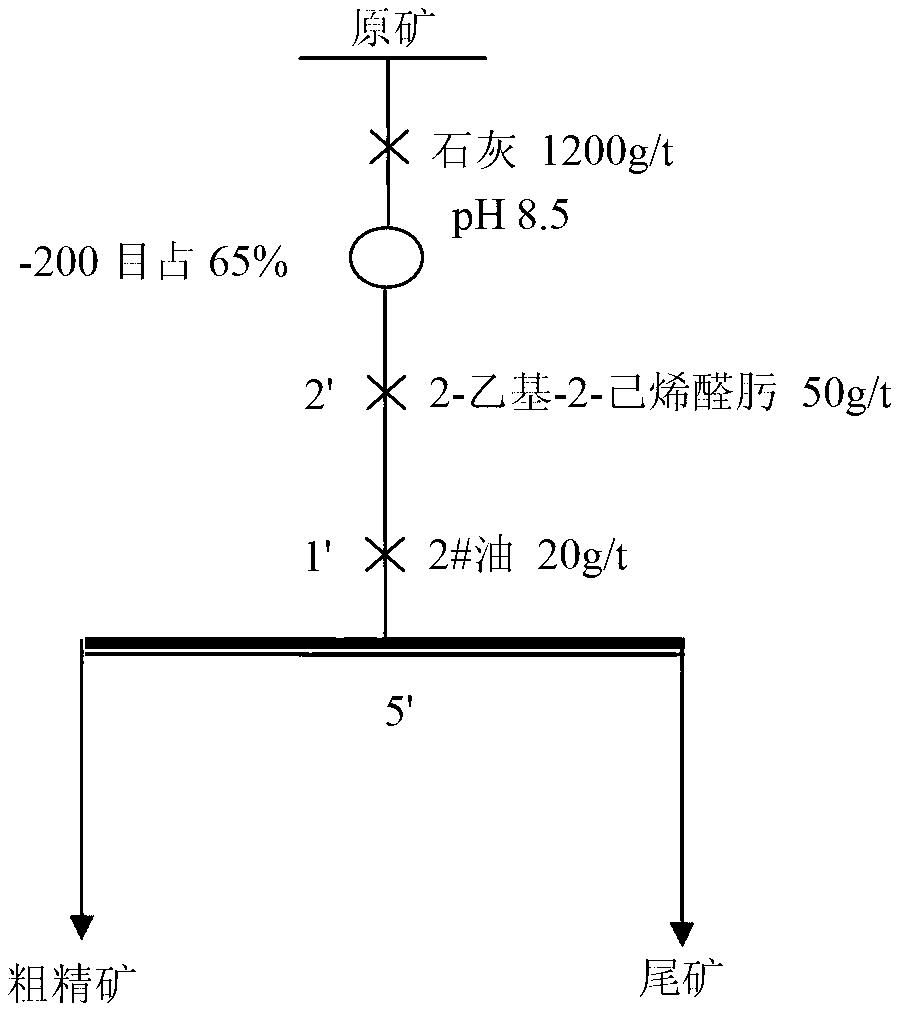

[0028] Application of embodiment 1,2-ethyl-2-hexenal oxime in copper sulfide ore flotation

[0029] The copper grade of a copper sulfide ore is 0.38%, the amount of lime is 1200g / t, the ore is ground to 65% and less than 200 mesh, and placed in a flotation tank, at a pH value of 8.5, the amount of foaming agent for No. 2 oil is 20g / t, 2- Flotation is carried out under the condition of ethyl-2-hexenaldoxime dosage of 50g / t, the flotation process flow chart is attached figure 2 . Table 1 shows the results of the flotation comparison experiment between the 2-ethyl-2-hexenaldoxime collector and the commonly used butyl xanthate collector in the present invention. It can be seen from the table that the flotation recovery rate of 2-ethyl-2-hexenaldoxime for copper sulfide ore is 2.47 percentage points higher than that of traditional butyl xanthate.

[0030] Table 1 Comparative experiment results of collector flotation copper sulfide ore

[0031] Collector

Embodiment 2

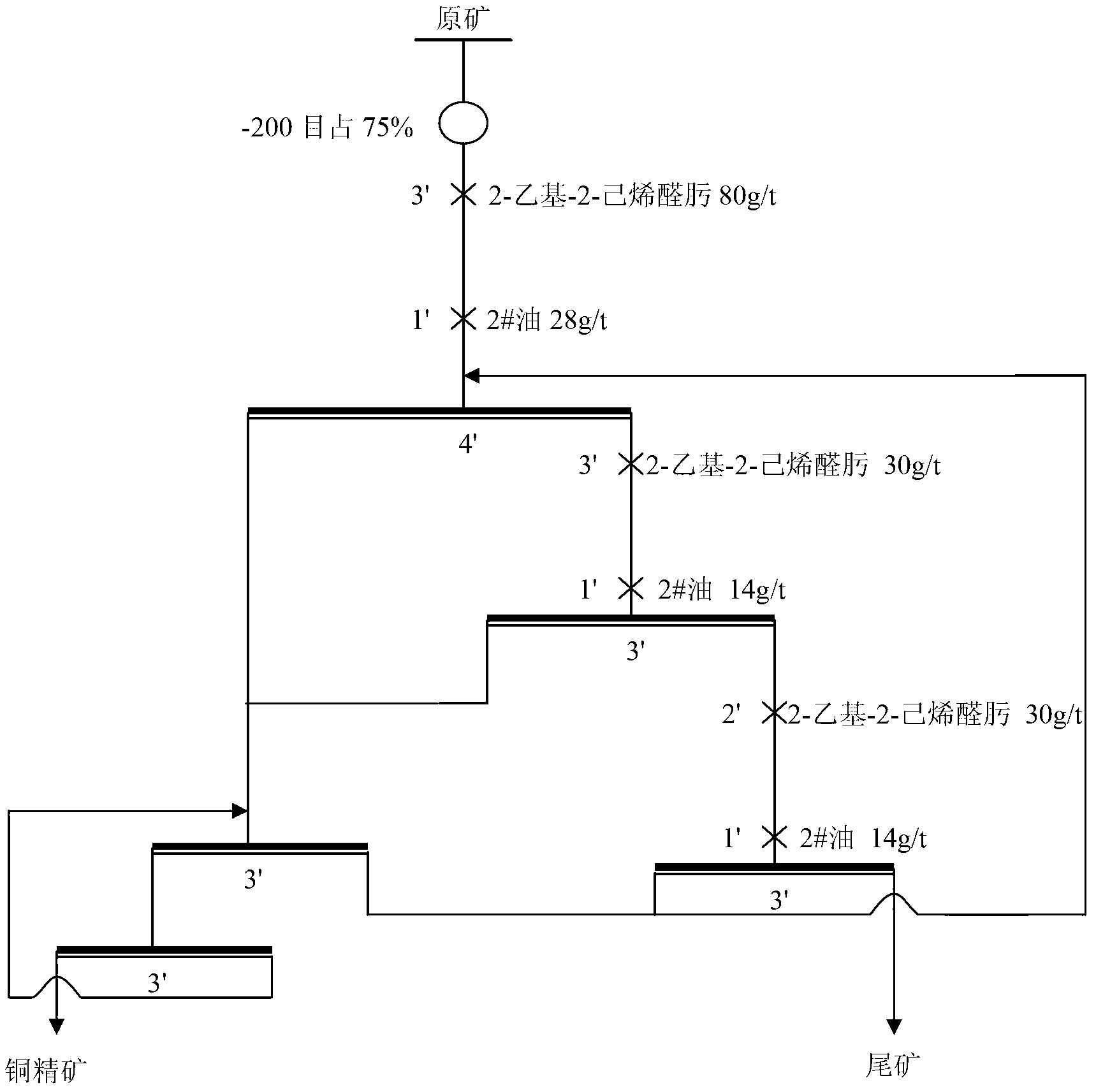

[0032] Embodiment 2, the application of 2-ethyl-2-hexenal oxime in sulfide-copper oxide ore flotation

[0033] The oxidation rate of a sulfide-oxidized copper ore is about 30%, the copper grade is 1.08%, the ore is ground to 75% and less than 200 mesh, and 80g of 2-ethyl-2-hexenaldoxime is added to the ore per ton in the first stage of roughing, Foaming agent No. 2 oil 28g, 2-ethyl-2-hexenaldoxime 30g per ton of ore feed for the second stage roughing, 14g of foaming agent No. Base-2-hexenaldoxime 30g, foaming agent No. 2 oil 14g, carry out the second roughing, the second selection, the first sweeping flotation experiment, the flotation process flow chart is attached image 3. Table 2 shows the results of the flotation comparison experiment between the 2-ethyl-2-hexenaldoxime collector and the commonly used butyl xanthate collector in the present invention. It can be seen from the table that the flotation recovery rate of 2-ethyl-2-hexenal oxime for copper sulfide-copper oxid...

Embodiment 3

[0036] Embodiment 3, the application of 2-ethyl-2-hexenal oxime in scheelite flotation

[0037] A high-sulfur scheelite ore WO 3 The grade is 0.46%, and the ore is ground until 80% is less than 200 meshes. First, desulfurization flotation is carried out. For desulfurization flotation, 40g butyl xanthate, 10g butylamine black medicine, and 36g foaming agent No. 2 oil are added to the ore per ton, and then Add 3000g of sodium carbonate, 2500g of water glass, 400g of 2-ethyl-2-hexenaldoxime per ton of ore for roughing flotation of scheelite, add 200g of 2-ethyl-2-hexene per ton of ore for sweeping For aldoxime, add 500g of water glass per ton of ore for the first selection, and add 300g of water glass per ton of ore for the second selection. The flotation process flow chart is attached Figure 4 . After a rough selection, a sweep, and two selection operations, WO will be obtained 3 Tungsten rough concentrate with a grade of 10.59% and a recovery rate of 86.27%. Table 3 shows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com