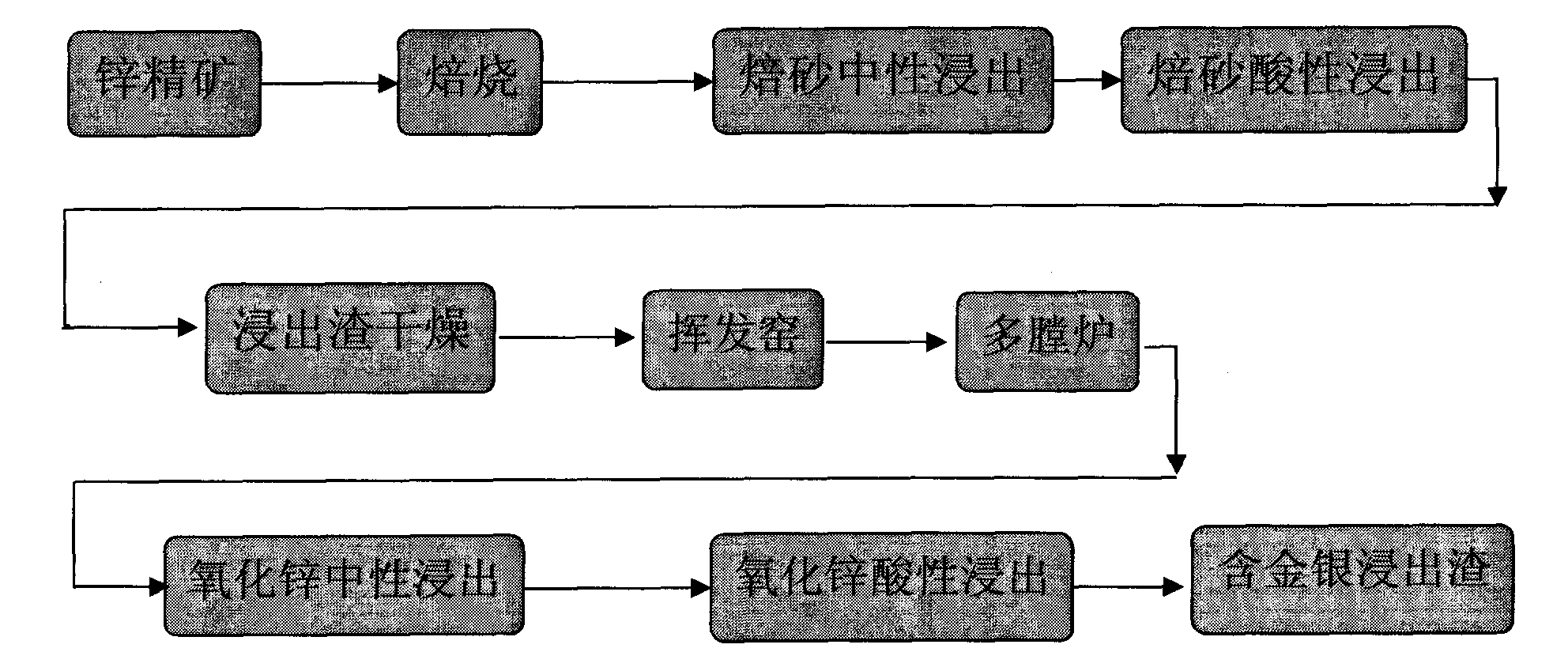

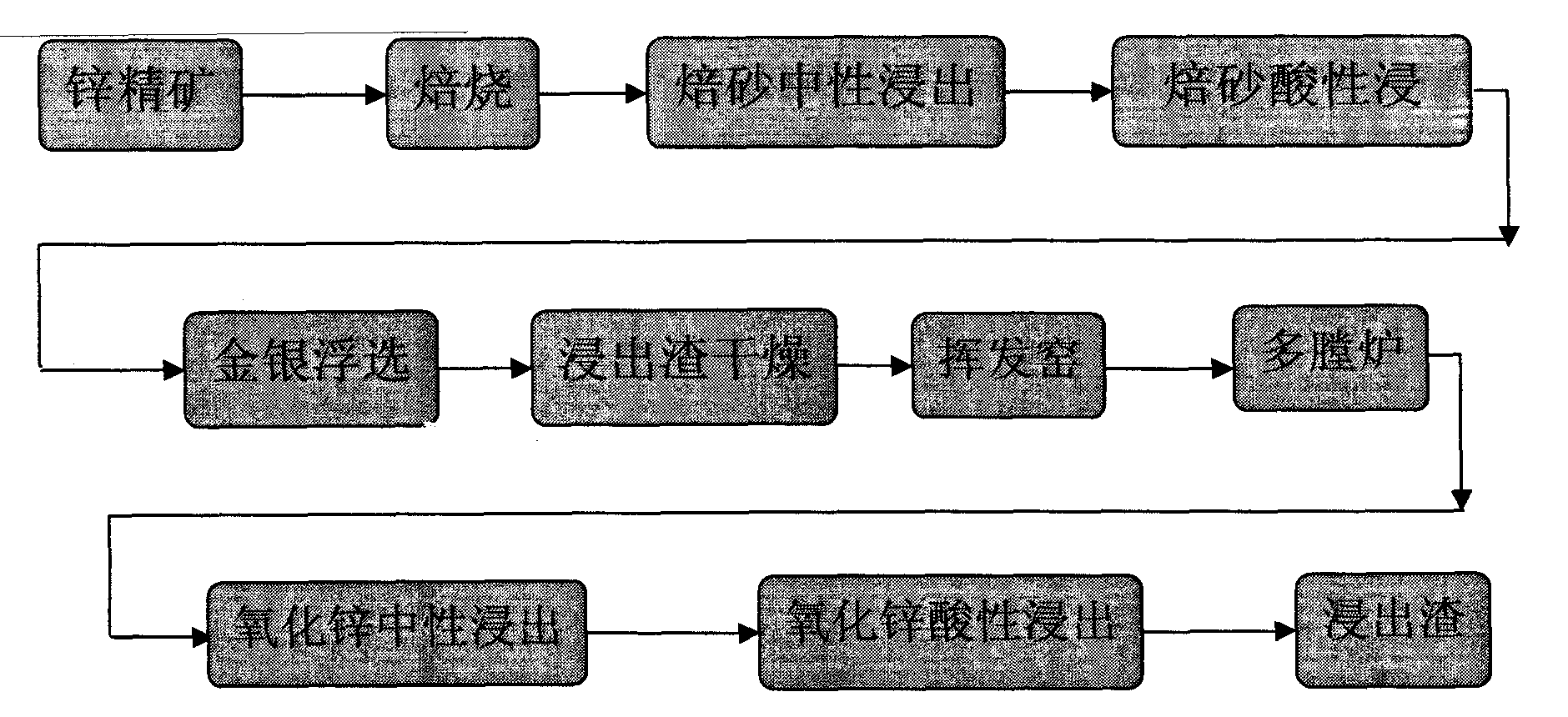

Process for reclaiming gold and silver by floatation from acid leaching ore pulp in wet zinc smelting

A technology of hydrometallurgy and ore pulp, which is applied in flotation, solid separation, etc., can solve the problems of waste of valuable resources and achieve the effects of maintaining concentration, reliable collection, and ensuring flotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A zinc hydrometallurgy company handles 600t of zinc concentrate calcine per day, and the pH of the pulp after acid leaching is 3-4, and the pulp is directly flotation for gold and silver.

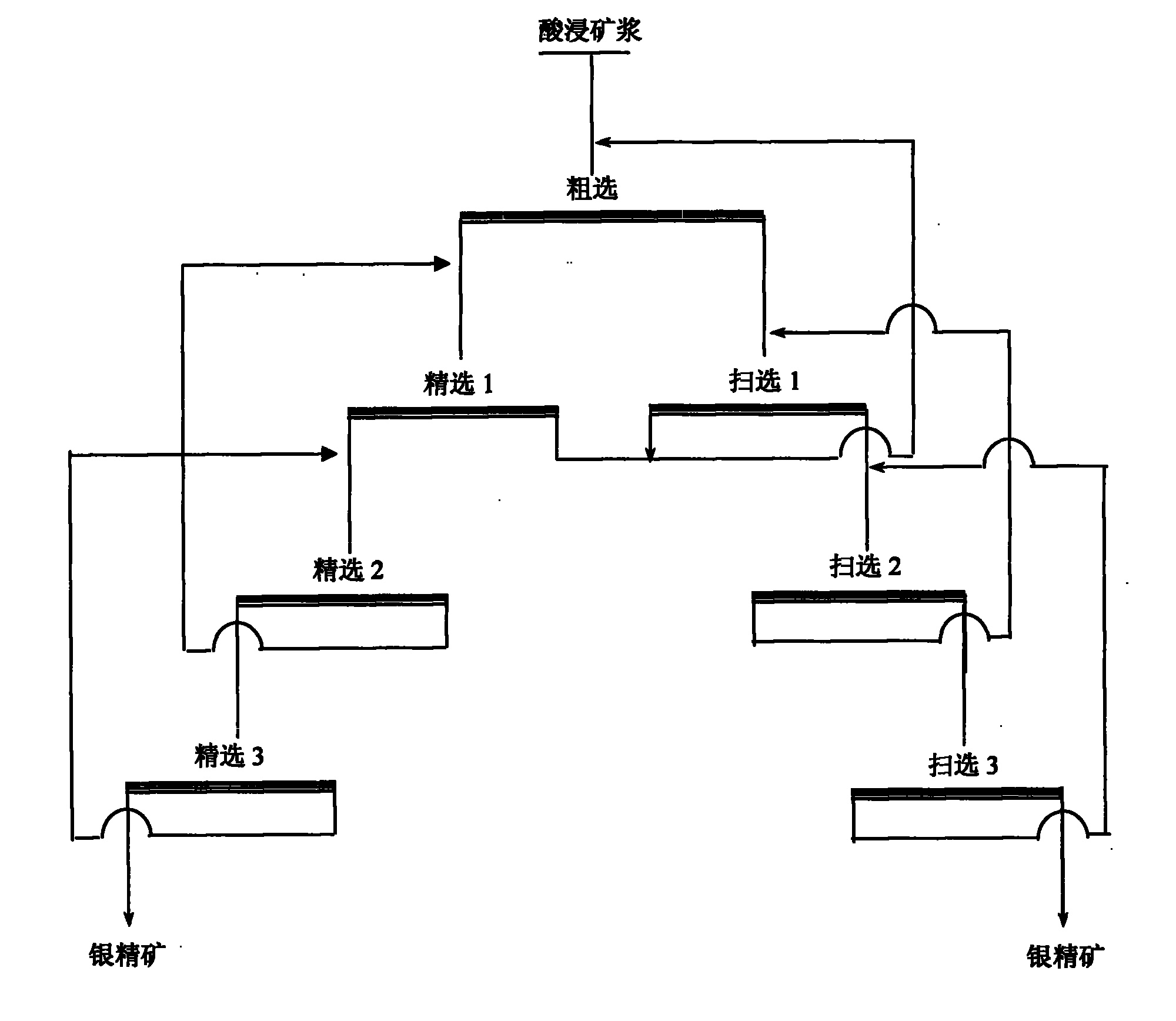

[0025] Flotation process such as image 3 As shown, the process features are:

[0026] ① Lead out the pulp after acid leaching of zinc concentrate calcine and send it into the pulp mixing tank, add an appropriate amount of zinc oxide regulator to the pulp, adjust the pH value of the pulp to 4-5, and then add capture to the pulp The collector is mixed with butyl xanthate and butylamine black drug, and the two components are mixed at a ratio of 1:1. The amount of collector is 200g / t; the foaming agent is 2# oil, the dosage is 60g / t;

[0027] ② Send the pulp in the mixing tank to the flotation system;

[0028] ③ In the flotation system, the new technology of point distribution and dosing is adopted, that is: in addition to the roughing process, the processes of fine one, fine two, fi...

Embodiment 2

[0033] A zinc industry company, with an annual output of 150,000 tons of zinc metal hydrometallurgy process, the acid leaching pulp pH is 3 to 4, and the flotation recovery of gold and silver is carried out.

example 1

[0034] Flotation process flow is the same as example 1, and the process features are:

[0035] ① Lead out the ore pulp after acid leaching of zinc concentrate calcine and send it into the pulp mixing tank, add collector and foaming agent to the pulp, and stir fully. The collector is sodium methyl isobutyl xanthate and No. 25 black drug composite collector, the two components are mixed at a ratio of 1:0.6, the total amount of collector is 240g / t; the foaming agent is ether alcohol, and the total amount is 60g / t;

[0036] ② Send the pulp in the mixing tank to the flotation system;

[0037] ③ In the flotation system, the new technology of point distribution and dosing is adopted, that is: in addition to the roughing process, the processes of fine one, fine two, fine three, sweep one, sweep two and sweep three in the flotation process are respectively Add composite collector and foaming agent, the amount of collector is 20g / t, 10g / t, 10g / t, 30g / t, 20g / t and 10g / t; the amount of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com