High sulfur copper ore collecting agent

A collector, copper ore technology, applied in solid separation, flotation and other directions, can solve problems such as unsatisfactory separation of copper and sulfur, loss of enterprises and society, and failure of beneficiation results to meet design requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

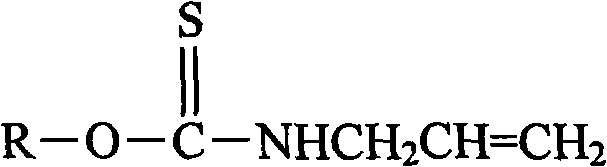

Image

Examples

Embodiment 1

[0021] a, preparation of isobutyl allyl thiocarbamate

[0022] Add 28.7Kg of commercially available isothiocyanate into a closed stainless steel reaction kettle heated by heat conduction oil, control the temperature at 110-120°C, stir and dehydrate for 2 hours to make the water in it evaporate completely, then add 19.7g of tetrabutyl titanate, Keep the reaction temperature at 115-125°C, and start to add isobutanol dropwise. The amount of isobutanol added is 21.4Kg, and the dropwise addition is completed in 1.8-2.2 hours. Keep the temperature at 110-120°C and continue the reaction for 3 hours to complete the reaction. Stand overnight and cool down to After room temperature, fill it into a plastic-lined iron drum, and the obtained brown oily product is isobutyl allyl thiocarbamate. The effective content of isobutyl allyl thiocarbamate in this reaction can reach 75%, and the yield is about 90%. .

[0023] b, preparation of thiazonitrile ester

[0024] Add 17Kg of carbon disulfi...

Embodiment 2

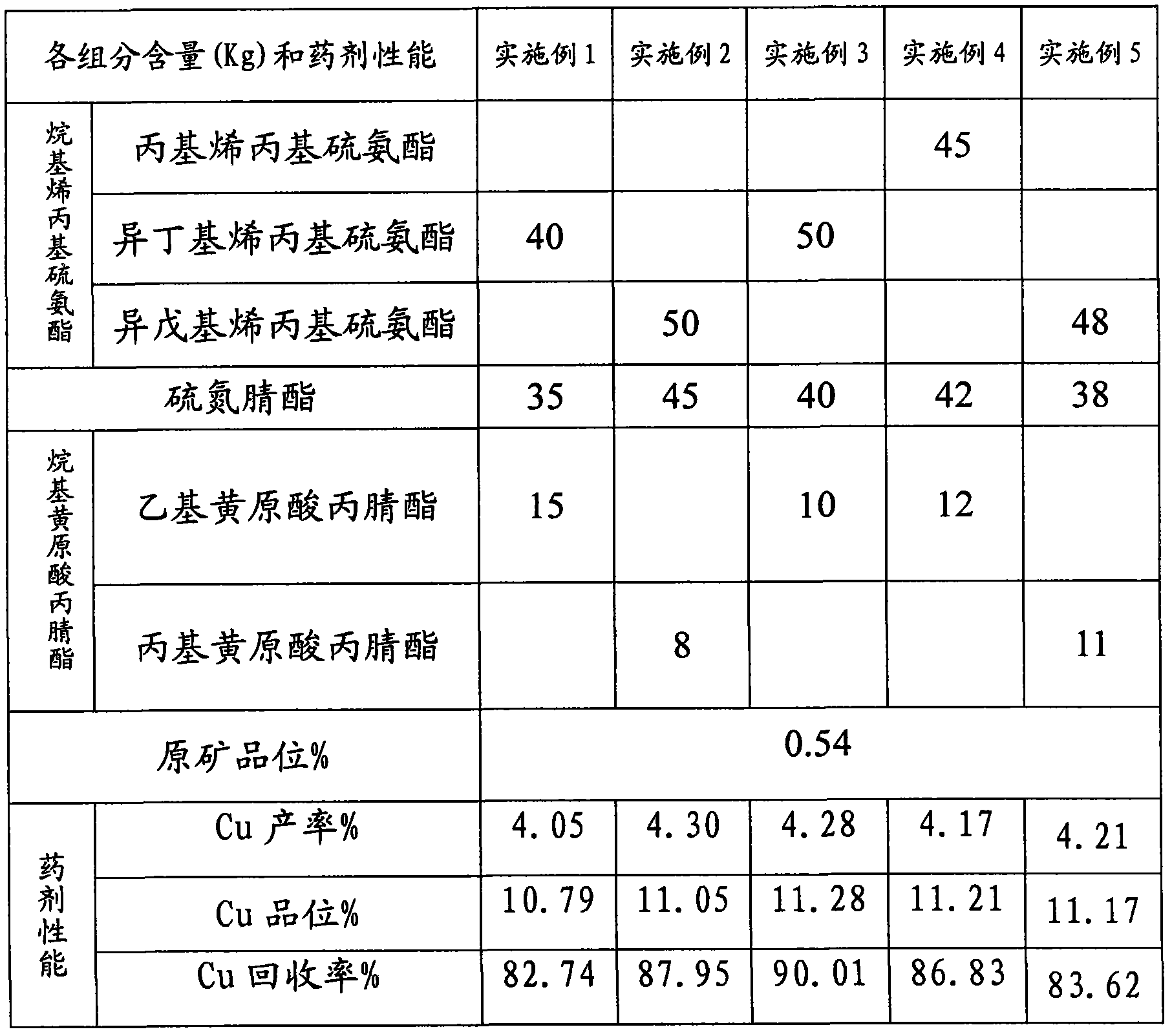

[0029] Add the content of each component specified in the following Table 1 into the stirring tank, and stir and mix at room temperature for 50 minutes to obtain the collector composition of the present invention. Then the collector was used for beneficiation test of copper ore, and the test results are listed in Table 1.

Embodiment 3

[0031] Add the content of each component specified in the following Table 1 into the stirring tank, and stir and mix at room temperature for 45 minutes to obtain the collector composition of the present invention. Then the collector was used for beneficiation test of copper ore, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com