Rutile flotation collector composition and application thereof

A collector and composition technology, which is applied in the field of rutile flotation, can solve the problems of poor flotation selectivity, high chemical cost, environmental pollution, etc., and achieve the effects of reducing dosage, improving flotation recovery rate, and improving collection capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

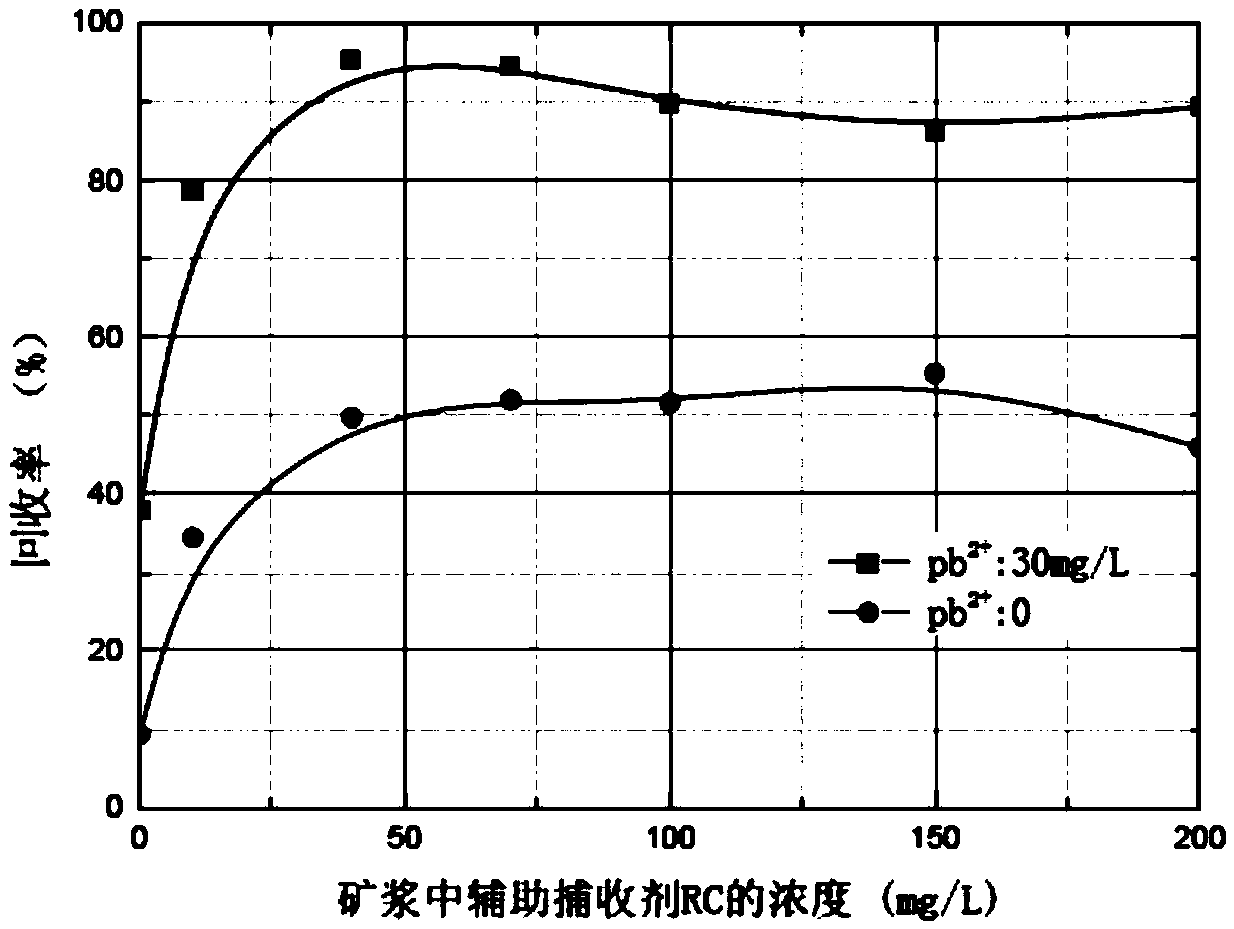

[0025] The impact of the consumption of embodiment 1 auxiliary collector RC on rutile flotation effect

[0026] A rutile flotation collector composition is composed of main collector salicylhydroxamic acid and auxiliary collector RC. The auxiliary collector RC is prepared by the following method: water, kerosene and TX-100 (HLB: 13.4) are mixed at a mass ratio of 100:5:0.15 to obtain an oil-water mixture; the oil-water mixture is placed in a high-shear dispersing emulsifier Disperse in 10000r / min rotation speed for 10min to obtain rutile auxiliary collector RC.

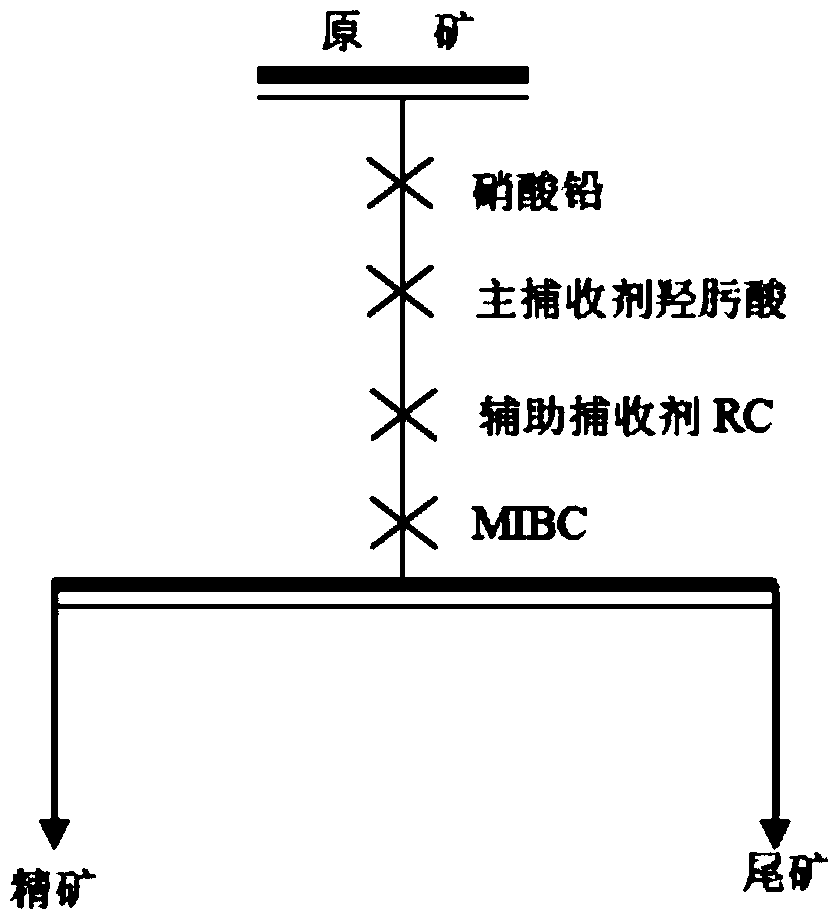

[0027] The application of the rutile flotation collector composition in the rutile flotation of this embodiment specifically comprises the following steps:

[0028] (1) Preparation of rutile pulp: Add 3 g of rutile single mineral with a particle size of -74 to +38 μm and 90 mL of distilled water into a 100 mL hanging tank flotation machine, stir and adjust the slurry at a speed of 1080 r / min to obtain rutile pulp;

...

Embodiment 2

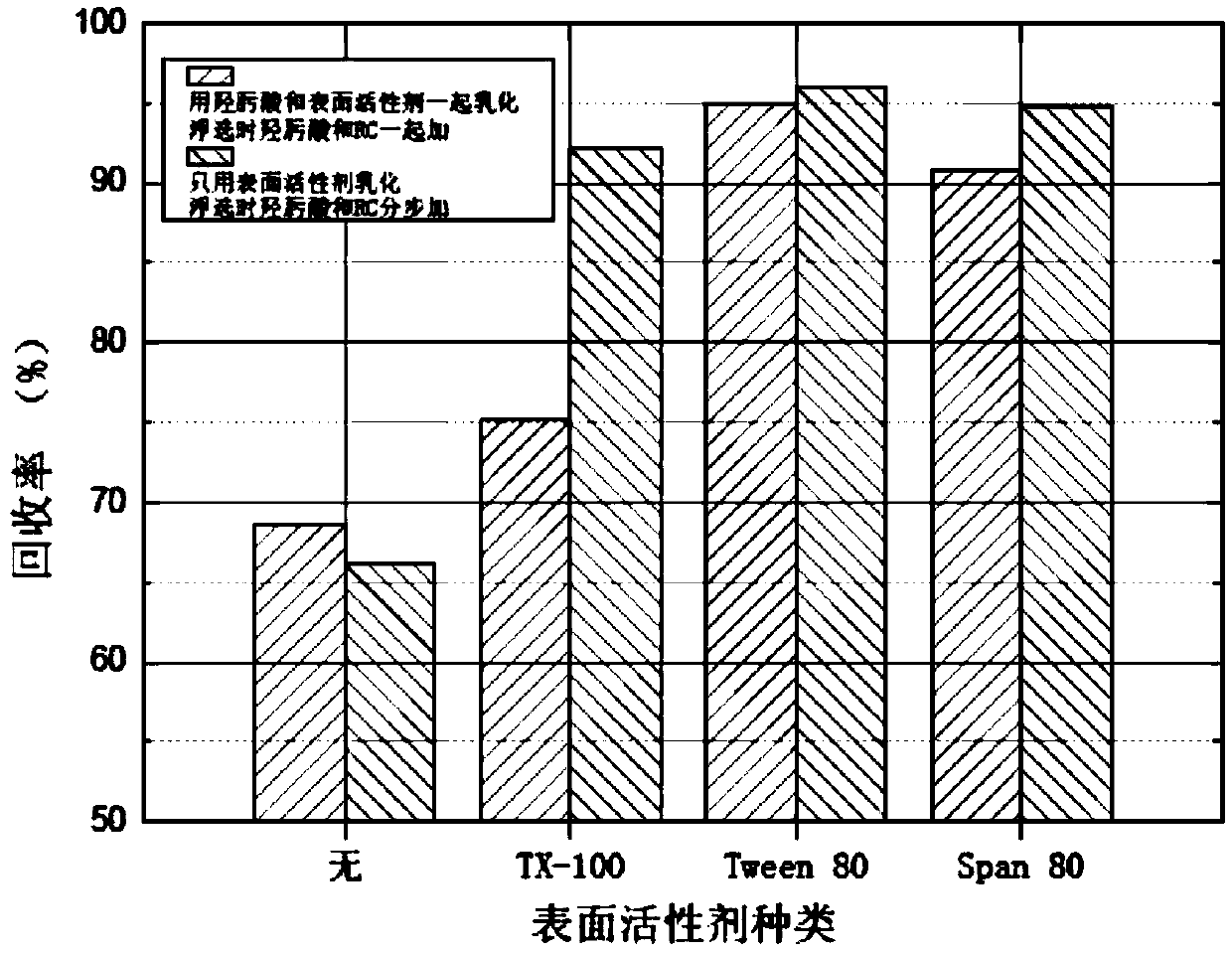

[0031] The impact of the surfactant type of the auxiliary collector RC on the flotation effect of rutile

[0032] A rutile flotation collector composition is composed of main collector salicylhydroxamic acid and auxiliary collector RC. The auxiliary collector RC is prepared by the following method: water, surfactant and diesel oil are mixed at a mass ratio of 100:0.03:1 to obtain an oil-water mixture; the oil-water mixture is placed in a high-shear dispersing emulsifier at 10000r / min Disperse for 10 minutes at a rotating speed to obtain rutile auxiliary collector RC; the surfactant is blank, TX-100 (HLB13.4), Tween80 (HLB: 15) or Span80 (HLB: 4.3), and the blank is used as a control.

[0033] The application of the rutile flotation collector composition in the rutile flotation of this embodiment specifically comprises the following steps:

[0034] (1) Preparation of rutile pulp: Add 3 g of rutile single mineral with a particle size of -74 to +38 μm and 90 mL of distilled wate...

Embodiment 3

[0037] The impact of the surfactant dosage of embodiment 3 auxiliary collector RC on rutile flotation effect

[0038] A rutile flotation collector composition is composed of main collector salicylhydroxamic acid and auxiliary collector RC. The auxiliary collector RC is prepared by the following method: water, Tween80 and kerosene are mixed in a mass ratio of 100:0:1, 100:0.003:1, 100:0.01:1, 100:0.03:1, or 100:0.05 : 1 mixed to obtain an oil-water mixture; the oil-water mixture was placed in a high-shear dispersing emulsifier and dispersed for 10 min at a rotating speed of 10000r / min to obtain the rutile auxiliary collector RC.

[0039]The application of the rutile flotation collector composition in the rutile flotation of this embodiment specifically comprises the following steps:

[0040] (1) Preparation of rutile pulp: Add 3 g of rutile single mineral with a particle size of -74 to +38 μm and 90 mL of distilled water into a 100 mL hanging tank flotation machine, stir and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com