Flotation reagent system for fine wolframite in gravity concentration tailings

A technology for gravity separation of tailings and flotation reagents, applied in flotation, solid separation and other directions, can solve problems such as high toxicity, seriousness, poor selectivity, etc. The effect of improving tungsten grade and tungsten recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

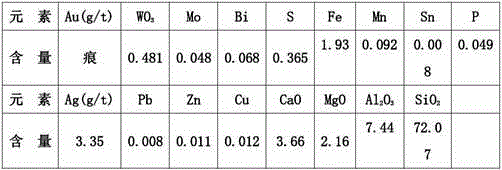

[0019] The sample is the gravity separation tailings of Xialong Tungsten Concentrator. The sample mainly contains tungsten, molybdenum, bismuth, sulfur and iron. Through the optical microscope identification of the sample ore, it is found that the content of metal minerals in tungsten fine mud is relatively small, accounting for only 1.91%. The main metal minerals are wolframite, scheelite, pyrite, pyrrhotite, pyrrhotite, Molybdenum ore, bismuthite, etc.; the contents are 0.58%, 0.19%, 0.43%, 0.32%, 0.07%, 0.05% respectively; the content of non-metallic minerals is relatively high, accounting for 98.09%. The chemical multi-element analysis results of the samples are shown in Table 1.

[0020] Table 1 Sample chemical multi-element analysis results (%).

[0021]

[0022] The sample was sieved through four sieves of 0.105mm, 0.075mm, 0.053mm, and 0.038mm to obtain 5 grades of products, and chemical analysis and lump ore inspection were carried out for each grade. According t...

Embodiment 2

[0029] The test sample is the overflow sample of Xialong Tungsten Industry's primary and secondary fine mud concentrated through a thickener, containing WO 3 , Mo, and Bi are 0.747%, 0.108%, and 0.107%, respectively. In the sample, wolframite mainly exists in the form of monomer, accounting for 94.32%, followed by gangue, accounting for 3.36%, and a small part of it is associated with pyrite and limonite. The particle size of wolframite is relatively fine, mainly distributed in the particle size range from -0.037mm to +0.010mm, accounting for 78.43%, see Table 4 for details.

[0030] Table 4 Statistical results of wolframite particle size (%).

[0031]

[0032] The sample contains molybdenum and bismuth with grades of 0.108% and 0.107% respectively. The sulfide is first floated to obtain the mixed concentrate of molybdenum and bismuth, and then molybdenum and bismuth are separated to obtain molybdenum concentrate and bismuth concentrate. The fine-grained wolframite is re...

Embodiment 3

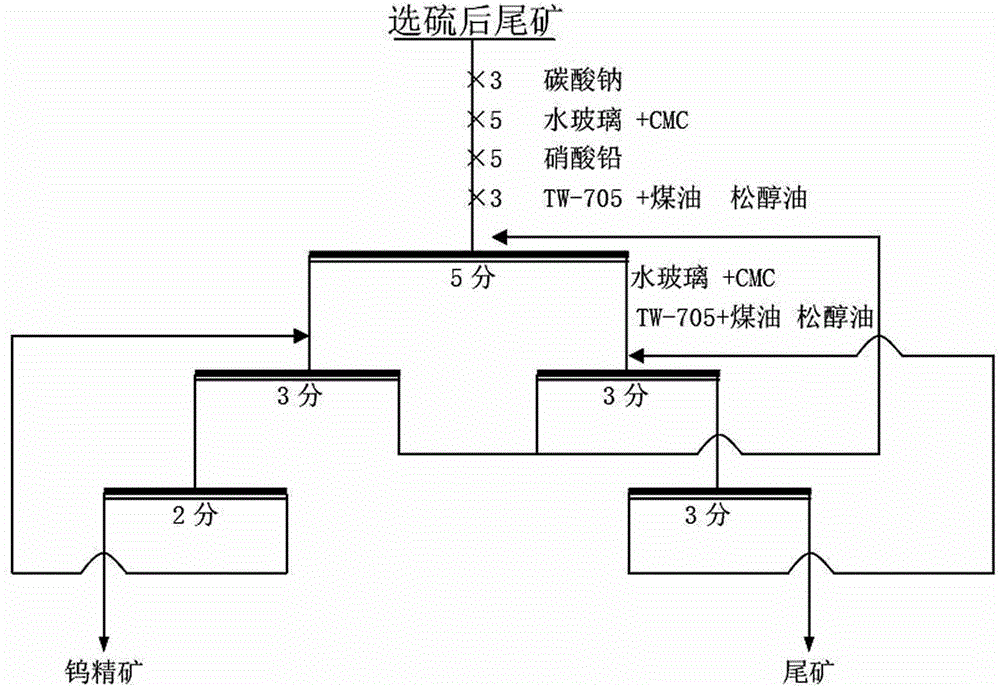

[0036] The sample is a raw material produced by a flotation plant in Dayu, which contains WO 3 0.527% slime. Using the technological process of one roughing, two sweepings, two beneficiations and the flotation agent system of the present invention, the mineral processing technical indicators obtained are shown in Table 6. The main technical parameters are: control the pulp concentration to 34%, add sodium carbonate 450g / t, at this time the pH value of the pulp is 7.8, and the stirring time is 3 minutes; add gangue inhibitor and fine mud dispersant, water glass + CMC cellulose , the dosage is 550g / t, and the stirring time is 5 minutes; the activator lead nitrate of wolframite is added, the dosage is 300g / t, and the stirring time is 5 minutes; the collector is TW-705+auxiliary collector kerosene, The dosage is 550g / t; the foaming agent is terpineol oil, the dosage is 25g / t, and the stirring time is 3 minutes.

[0037] Table 6 Fine Sludge Wolframite Flotation Index (%)

[0038...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com