Beneficiation method for silicate and carbonate type fluorite ores

A beneficiation method and carbonate technology, which is applied in the mineral beneficiation of carbonate type fluorite ore and the field of silicate, can solve the problems of high impurity content and low recovery rate of concentrate products, and achieve easy on-site implementation and control, The effect of reducing the content of silica and calcium carbonate and reducing the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

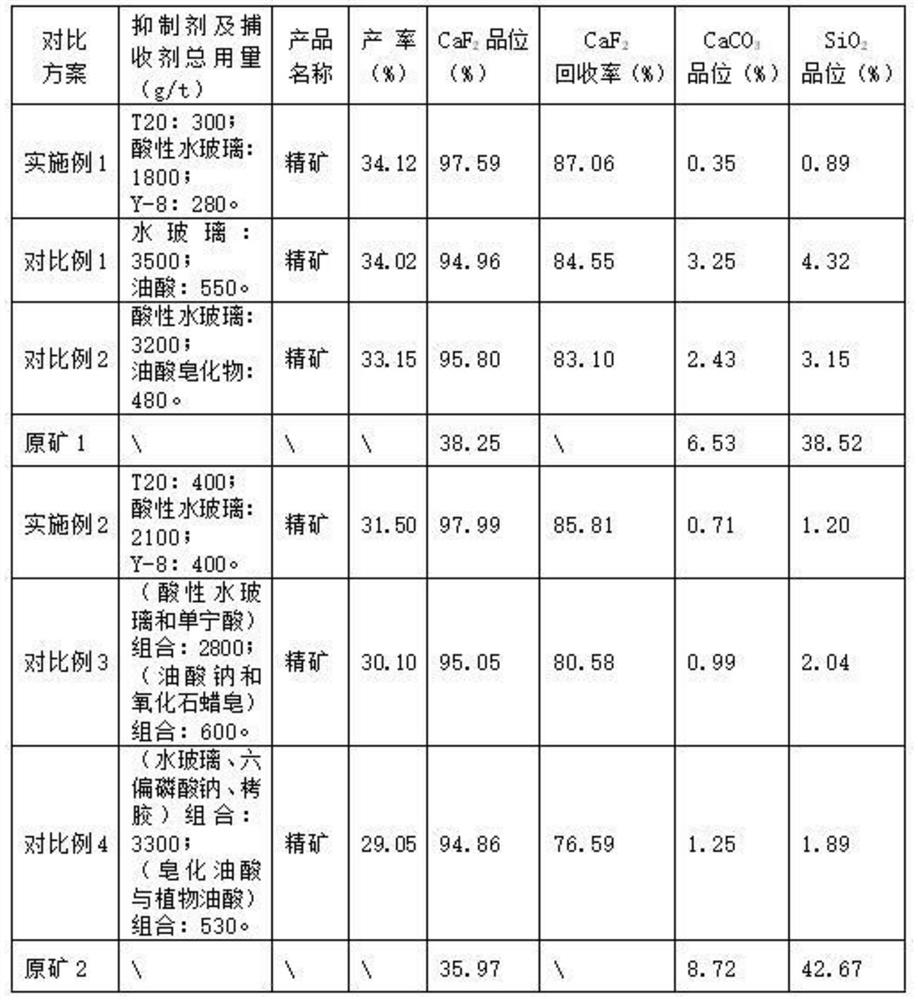

[0028] A certain fluorite mine in Gansu has a relatively simple mineral composition. The ore mineral is only fluorite, the gangue mineral is mainly quartz, a small amount of calcite, clay mineral kaolin, etc. Some fluorite (approximately 10%) is mixed with gangue minerals such as quartz, clay minerals, and calcite. The particle size is fine and the intercalation relationship is complicated, making it difficult for the monomer to dissociate. Raw ore (ie, raw ore 1 in Table 1) test ore sample CaF 2 Grade 38.25%, CaCO 3 Grade 6.53%, SiO 2 The grade is 38.52%.

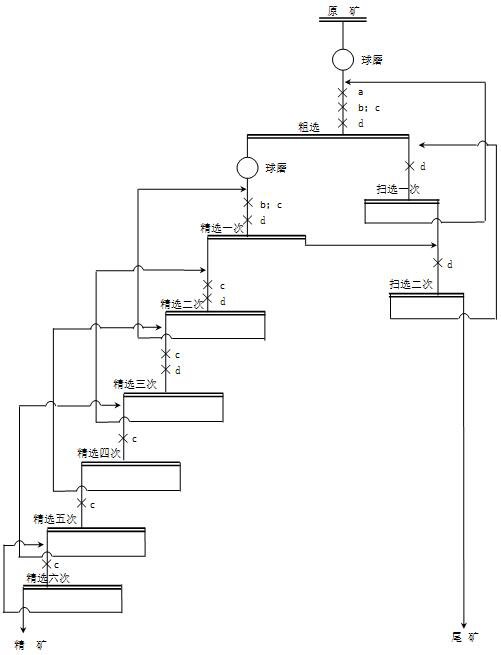

[0029] Step 1. Grinding: Grinding the ore to a particle size of 74μm or less, accounting for 60%;

[0030] Step 2. Rough separation operation: heat the pulp to 20°C, use sulfuric acid (a) as the pH adjuster, the amount of sulfuric acid (a) is 350g / t, and use gangue inhibitor T20( b) Combined with acid water glass (c), the dosage of gangue inhibitor T20(b) is 200g / t, the dosage of acid water glass (c) is 600g / t, and the dosage ...

Embodiment 2

[0043] A fluorite mine in Inner Mongolia has a relatively simple mineral composition, and the useful mineral is fluorite. Gangue minerals are mainly quartz, a small amount of mica, calcite, chlorite, kaolin, etc. Fluorite has a close relationship with quartz inlays, and the two are mainly adjacent and connected, and partly wrapped. Raw ore (ie, raw ore 2 in Table 1) CaF 2 Grade is 35.97%, SiO 2 Grade is 42.67%, CaCO 3 The grade is 8.72%.

[0044] Step 1. Grinding: Grinding the ore to a particle size below 74μm, accounting for 70%;

[0045] Step 2. Rough separation operation: heat the pulp to 25℃, use sulfuric acid as pH adjuster, sulfuric acid (a) dosage is 500g / t, gangue inhibitor T20(b) and gangue inhibitor Combination of acid water glass (c), the dosage of gangue inhibitor T20(b) is 250g / t, the dosage of acid water glass (c) is 800g / t, and the dosage of collector Y-8(d) is 180g / t. Rough separation of fluorite ore, the PH value of the pulp is 7, and the flotation time is 10 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com