A kind of anticorrosion and antimildew water-based epoxy curing agent and preparation method thereof

A water-based epoxy, anti-corrosion and anti-mold technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of general anti-corrosion and anti-mold performance, expensive raw materials, high cost, etc., to reduce later maintenance Cost, improve corrosion resistance, good anti-fouling and anti-mildew performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

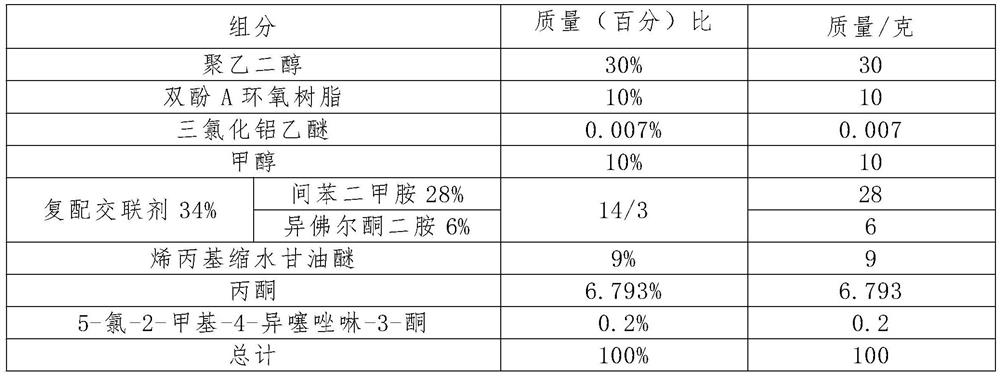

[0027] The present embodiment provides a high corrosion environment-friendly waterborne epoxy curing agent, component mass, and component is a curing agent as follows:

[0028]

[0029] Embodiment, bisphenol A epoxy resin epoxy value 0.4 embodiment, the polyethylene glycol molecular weight of 4,000, mass compound crosslinker-xylylenediamine and isophoronediamine ratio 14 / 3.

[0030] The present embodiment also provides a method of preparing a waterborne epoxy curing agent, antiseptic mildew, comprising the steps of:

[0031] (1) with stirring at room temperature, 30 g of polyethylene glycol melted in a water bath heated to 50 deg.] C, then 10 g of bisphenol A epoxy resin mixed;

[0032] (2) heating the material in the previous step, to be heated up to 85 ℃ dropwise 0.007 g of aluminum chloride ether solution, to heat the reaction system was dissolved, then cooled to room temperature, quenched with 10 g of a methanol, stirred for 30 min;

[0033] (3) the previous step were heated...

Embodiment 2

[0036] The present embodiment provides a high corrosion environment-friendly waterborne epoxy curing agent, component mass, and component is a curing agent as follows:

[0037]

[0038] Embodiment, bisphenol A epoxy resin epoxy value 0.48, the molecular weight of polyethylene glycol 5000, mass-xylylenediamine and isophorone diamine compound ratio of crosslinking agent present embodiment 12 / 5.

[0039] The present embodiment also provides a method of preparing a waterborne epoxy curing agent, antiseptic mildew, comprising the steps of:

[0040] (1) with stirring at room temperature, 25 g of polyethylene glycol was heated to 60 deg.] C water bath melted, then added 20 g of bisphenol A epoxy resin mixed;

[0041] (2) heating the material in the previous step, to be heated up to 95 deg.] C was added dropwise 0.002 g of boron trifluoride ether solution, 8 grams of the reaction was quenched incubation mixture was dissolved to the system, and then cooled to room temperature, was added ...

Embodiment 3

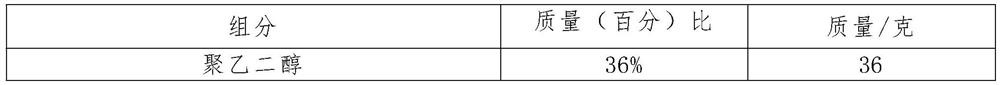

[0045] The present embodiment provides a high corrosion environment-friendly waterborne epoxy curing agent, component mass, and component is a curing agent as follows:

[0046]

[0047]

[0048] In this embodiment, the hydrogenated epoxy value of 0.52 epoxy resins, polyethylene glycol molecular weight of 6000, the mass ratio of m-xylylenediamine and isophorone diamine compound crosslinker was 5 / 3.

[0049] The present embodiment also provides a method of preparing a waterborne epoxy curing agent, antiseptic mildew, comprising the steps of:

[0050] (1) with stirring at room temperature, 36 g of polyethylene glycol was heated to 70 deg.] C water bath melted, 18 g of hydrogenated epoxy resin was then added uniformly mixed;

[0051] (2) heating the material in the previous step, to be heated up to 100 deg.] C was added dropwise 0.004 g of aluminum chloride ether solution, to heat the reaction system was dissolved, then cooled to room temperature, quenched with 5 g of a methanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com