Antibacterial and antifungal shell powder coating

A technology of antibacterial and antifungal, antibacterial and antifungal agent, applied in the direction of antifouling/underwater coating, coating, paint containing biocide, etc., can solve the problems of unfavorable irritating smell, poor antifungal effect, etc., and achieve environmental protection Antibacterial and antifungal effect, good antibacterial and antifungal effect, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

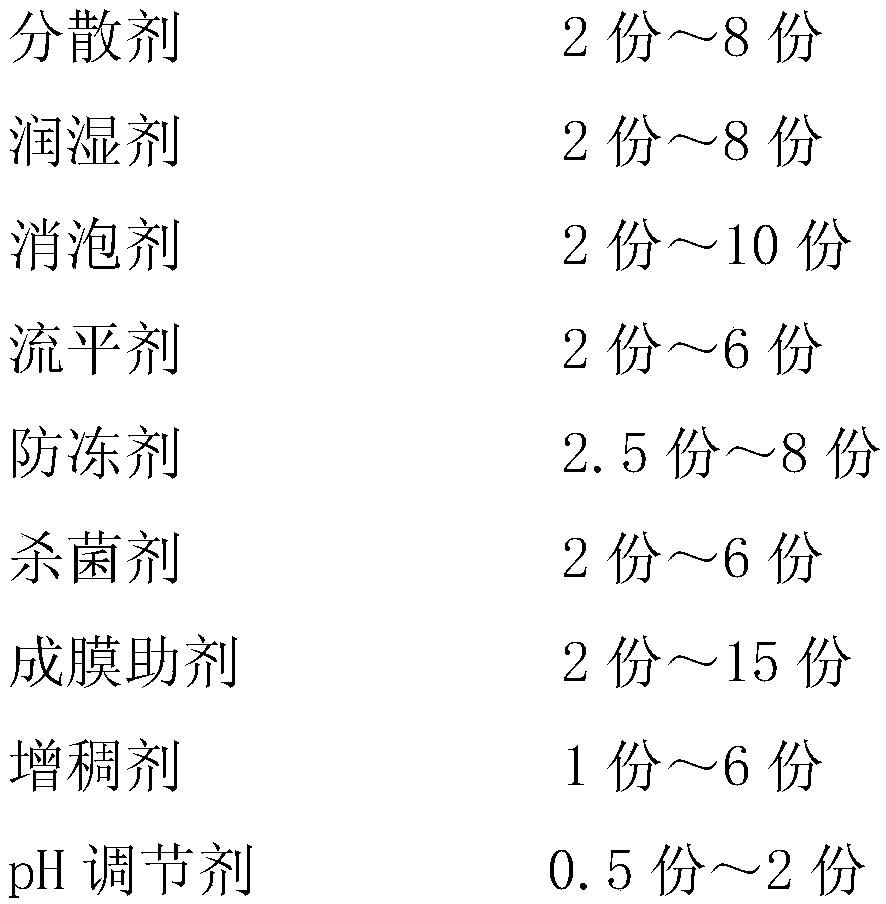

[0041] A preparation method for antibacterial and mildew-proof shell powder coating, comprising the following steps:

[0042] Step 1. According to the proportion, mix the deionized water, dispersant, wetting agent, defoamer, leveling agent, antifreeze, bactericide, and film-forming aid in the raw materials evenly to obtain a mixed liquid;

[0043] Step 2. According to the proportion, add antibacterial and antifungal agent, shell powder, heavy calcium carbonate, light calcium carbonate, titanium dioxide and beat at high speed to make the powder mix evenly to obtain a mixed slurry;

[0044] Step 3: Add emulsion, pH regulator and thickener according to the proportion and mix evenly to obtain the antibacterial and mildew-proof shell powder coating.

[0045] The preparation method of described antibacterial antifungal agent, comprises the following steps:

[0046] Step 1. Mix the molecular sieve and nano-zinc oxide evenly according to the proportion, and calcinate the obtained mix...

Embodiment 1

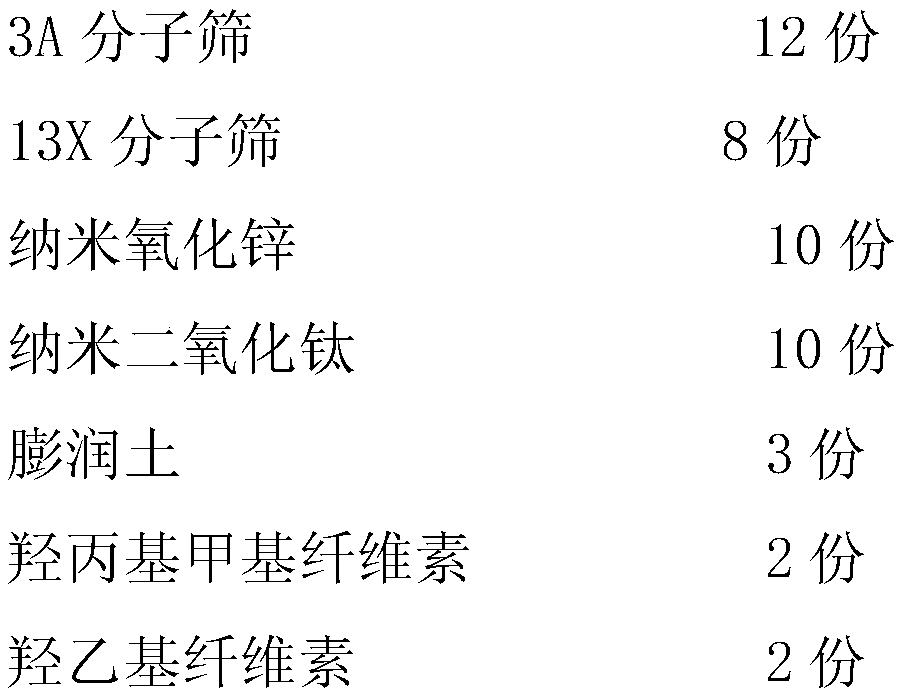

[0050] 1. Composition of antibacterial and antifungal agents

[0051]

[0052] According to the formula quantity of this example, 3A molecular sieve and 13X molecular sieve were mixed with nano-zinc oxide evenly, calcined at 600° C. for 2.5 hours, and nano-zinc oxide was loaded on the molecular sieve at high temperature. After the calcined powder cools down, use a dry powder grinder to grind the powder for 1 hour, so that the calcined mixed powder I can be better mixed with other powders. Then mix the mixed powder I with nano-titanium dioxide, and calcine it at a temperature of 300°C for 4 hours. After the calcined powder cools down, use a dry powder mill to grind the powder for 0.5 hours, so that the calcined mixed powder II can be more Blends well with other powders. Finally, add bentonite, hydroxypropylmethylcellulose and hydroxyethylcellulose, mix in a powder mixer for 0.5h, and discharge to obtain an antibacterial and antifungal agent.

[0053] 2. Preparation of antiba...

Embodiment 2

[0058] 1. Composition of antibacterial and antifungal agents

[0059]

[0060] According to the formula quantity in this example, the activated molecular sieve powder and nano-zinc oxide were evenly mixed, calcined at a temperature of 400°C for 4 hours, and the nano-zinc oxide was loaded on the molecular sieve at high temperature. After the calcined powder cools down, use a dry powder grinder to grind the powder for 1 hour, so that the calcined mixed powder I can be better mixed with other powders. Then mix the mixed powder I with nano-titanium dioxide, and calcined at 400°C for 2 hours. After the calcined powder cools down, use a dry powder grinder to grind the powder for 0.5 hours, so that the calcined mixed powder II can be more Blends well with other powders. Finally, add bentonite, hydroxypropylmethylcellulose and hydroxyethylcellulose, mix in a powder mixer for 0.5h, and discharge to obtain an antibacterial and antifungal agent.

[0061] 2. Preparation of antibacter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com