Plant environment-friendly mildew-proof antibacterial coating and preparation method thereof

An anti-mildew, antibacterial and environmentally friendly technology, applied in the field of coatings, which can solve the problems of dosage requirements, skin irritation, and slow decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

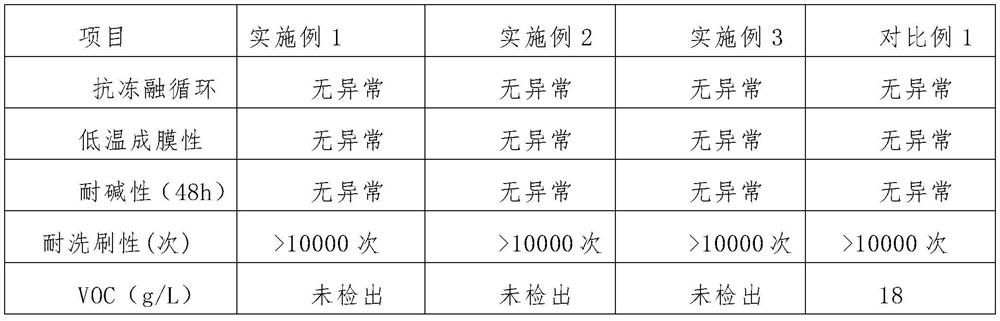

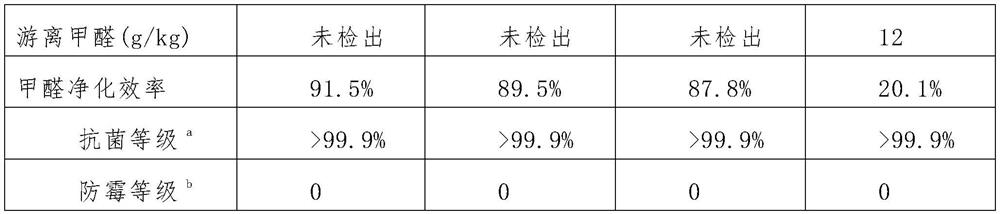

Examples

preparation example Construction

[0034] A kind of preparation method of plant environment-friendly mildew-resistant and antibacterial paint, concrete steps are as follows:

[0035] Step S1: Add water, hydroxyethyl cellulose, and pH adjuster in order to disperse for 2-4 minutes at a speed of less than 600 rpm in the reaction kettle;

[0036] Step S2: Keep the speed of the reaction kettle constant, add natural plant antibacterial and antifungal agents, and disperse for 2-5 minutes;

[0037] Step S3: Increase the speed of the reactor to 600-1000rpm, add water-based wetting agent, water-based dispersant, defoamer, titanium dioxide, calcined kaolin, calcium carbonate, diatomaceous earth, and ultrafine zinc oxide in sequence, and increase the speed of the reactor To 1200-1500rpm, disperse for 15-25min;

[0038] Step S4: Adjust the rotation speed of the reaction kettle to 700-1000 rpm, add emulsion, antifreeze, and film-forming aid in sequence and continue stirring for 10-15 minutes to obtain a finished product.

...

Embodiment 1

[0043] Adjust the speed of the reaction kettle to 500rpm, add 28 parts of water, 0.4 part of hydroxyethyl cellulose, 0.5 part of water-based dispersant, 0.2 part of water-based wetting agent, 1 part of natural plant antibacterial and anti-fungal agent, 0.2 part of water-based defoamer, and Increase the speed of the reaction kettle to 1000rpm, add 18 parts of titanium dioxide, 9 parts of kaolin, 15 parts of calcium carbonate, 13 parts of diatomaceous earth, and 2 parts of ultrafine zinc oxide, continue to increase the speed of the reaction kettle to 1300rpm, and stir for 20min. After mixing evenly, reduce the speed of the reactor to 1000rpm, continue to add 22 parts of emulsion, 0.5 part of antifreeze, 0.8 part of film-forming aid, and 0.3 part of water-based defoamer, and stir for 15 minutes to obtain this product.

Embodiment 2

[0045]Adjust the speed of the reaction kettle to 600rpm, add 30 parts of water, 0.4 parts of hydroxyethyl cellulose, 0.5 parts of water-based dispersant, 0.2 parts of water-based wetting agent, 1.5 parts of natural plant antibacterial and anti-fungal agent, and 0.2 parts of water-based defoamer. Increase the speed of the reaction kettle to 900rpm, add 16 parts of titanium dioxide, 8 parts of kaolin, 13 parts of calcium carbonate, 15 parts of diatomaceous earth, and 1.5 parts of ultrafine zinc oxide, continue to increase the speed of the reaction kettle to 1300rpm, stir for 15 minutes, and mix After uniformity, reduce the speed of the reactor to 1000 rpm, continue to add 23 parts of emulsion, 0.5 part of antifreeze, 0.8 part of film-forming aid, and 0.3 part of water-based defoamer, and stir for 12 minutes. Get this product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com