Graphene/alkane composite coating for aluminum alloy plate strip and preparation method thereof

A technology of aluminum alloy strips and composite coatings, which is applied in the direction of coatings, anti-corrosion coatings, and devices for coating liquid on the surface, which can solve the problems of poor corrosion resistance and environmental protection of conversion coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

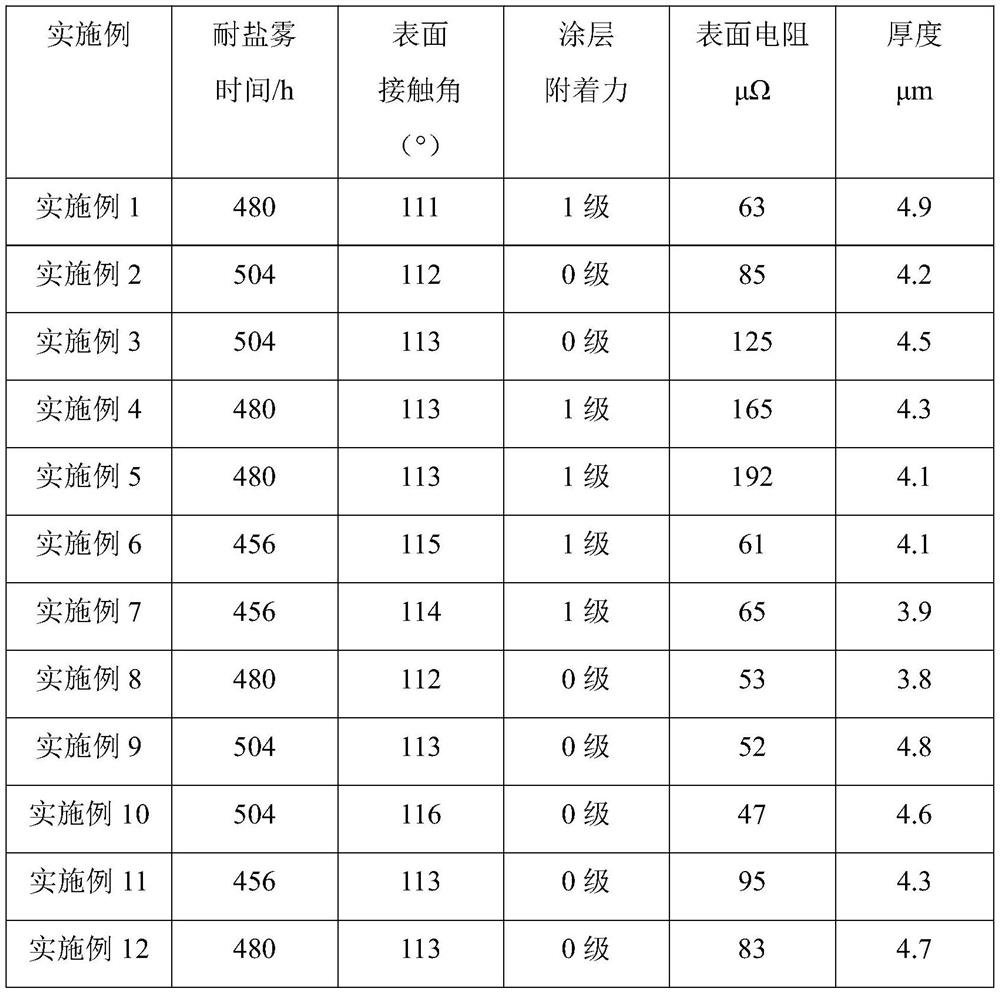

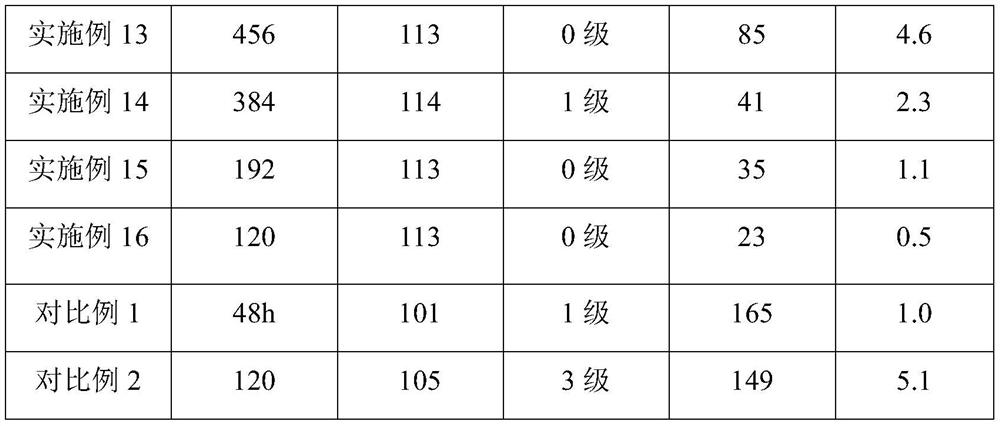

Examples

Embodiment 1

[0036] A kind of preparation method of graphene / alkane composite coating for aluminum alloy strip comprises the following steps:

[0037] (1) Surface pretreatment: The aluminum alloy plate with a width of 50 cm is subjected to alkali washing, degreasing, and hot air drying.

[0038] (2) Coating preparation: add graphene with a surface oxygen / carbon ratio of 1:30 to n-dodecane and n-tridecane (mass ratio 2:1), stir mechanically for 30 minutes, and then place it under low-temperature circulating water conditions for ultrasonication Disperse for 30 minutes, keep the temperature of the coating at 35°C to 45°C, prepare graphene dispersion A; add N-β-(aminoethyl)-γaminopropyltrimethoxysilane coupling agent to graphene dispersion under stirring In liquid A, continue mechanical stirring and aging for 12 hours to prepare graphene dispersion B; add graphene dispersion B to n-dodecane and n-tridecane, and mechanically stir for 30 minutes to prepare a coating. Graphene accounts for 0.01%...

Embodiment 2~5

[0041] Examples 2-5: Different from Example 1, the surface oxygen / carbon ratios of graphene (according to the examples) are 1:15, 1:10, 1:5, 1:1.

Embodiment 6-8

[0042] Embodiment 6-8: Different from Embodiment 1, the coupling agent (according to the embodiment) is γ-aminopropylmethyldiethoxysilane, anilinomethyltriethoxysilane, diethylamino Substituted methyltriethoxysilane and aminopropyltriethoxysilane, the mass ratio is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com