UV radiation curing heat dissipation paint containing graphene and preparation method of paint

A heat-dissipating coating and radiation curing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor compatibility of resin systems, poor thermal conductivity, poor heat dissipation, and easy agglomeration of graphene to achieve excellent thermal conductivity , good flexibility, avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

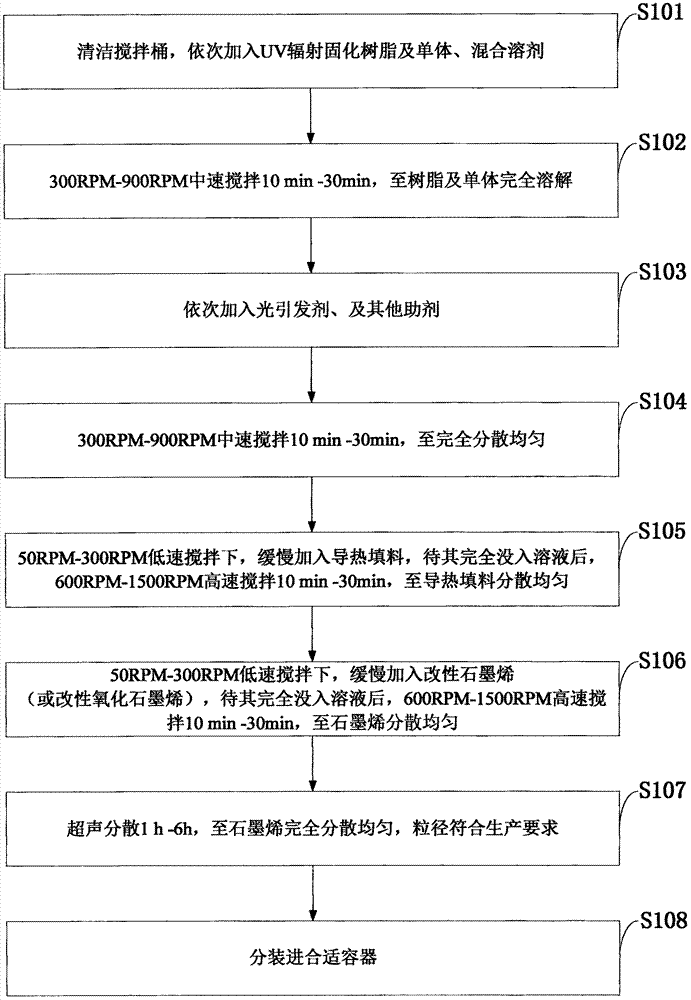

[0056] Such as figure 1 As shown, the preparation method of the graphene-containing UV radiation curable heat dissipation coating provided by the embodiment of the present invention includes the following steps:

[0057] S101: Clean the mixing tank, add UV radiation curing resin, monomer, and mixed solvent in sequence;

[0058] S102: Stir at medium speed of 300RPM-900RPM for 10min-30min, until the resin and monomer are completely dissolved;

[0059] S103: Add photoinitiator and other additives in sequence;

[0060] S104: 300RPM-900RPM medium speed stirring for 10min-30min, until completely dispersed and uniform;

[0061] S105: Under 50RPM-300RPM low-speed stirring, slowly add the thermally conductive filler, after it is completely submerged in the solution, stir at 600RPM-1500RPM for 10-30min at high speed until the thermally conductive filler is evenly dispersed;

[0062] S106: Under 50RPM-300RPM low-speed stirring, slowly add modified graphene (or modified graphene oxide). After it is...

Embodiment 1

[0086] The graphene-containing UV radiation curable heat dissipation coating of the present invention is composed of 35% UV radiation curable resin and monomer, 58% mixed solvent, 3% photoinitiator, 3.9% auxiliary agent and 0.1% modified graphene or Modified graphene oxide composition.

[0087] The specific composition of each component is as follows:

[0088] Among them, 35% of UV radiation curing resins and monomers can use 20% of difunctional urethane acrylate resin and 15% of hexafunctional urethane acrylate resin.

[0089] For 58% of the mixed solvent, 30% ethyl acetate, 15% ethanol, 8% butyl acetate, and 5% propylene glycol methyl ether acetate can be used.

[0090] For 3% of the photoinitiator, 1% of the photoinitiator 200 and 2% of the photoinitiator 1173 can be used.

[0091] Among them, 3.9% of additives can be used 0.3% of leveling agent BYK-333, 0.6% of leveling agent Tego-410, 1% of ultraviolet absorber Tinuvin-292, and 2% of polythiol.

[0092] Among them, 0.1% of modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com