Acrylic acid modified water-based stoving varnish alkyd resin and preparation method thereof

A technology of alkyd resin and acrylic acid, which is applied in the direction of coating, etc., can solve the problems of gloss, hardness, and chemical resistance that cannot meet the needs of users, the quality of water-based resins is uneven, and the environmental protection performance is insufficient, so as to reduce environmental pollution. Burden, superior chemical resistance, superior abrasion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

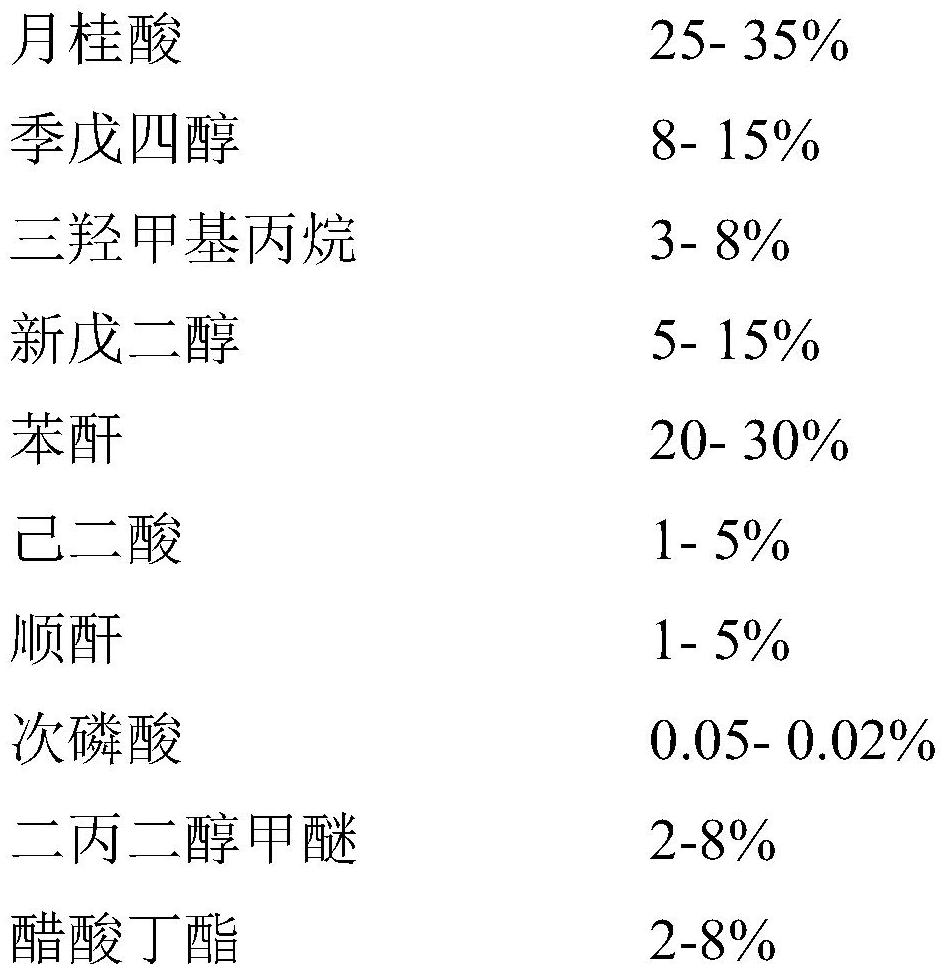

[0024] one step reaction

[0025] a. Add 30.4% lauric acid, 12.4% pentaerythritol, 6.6% trimethylolpropane, 8.96% neopentyl glycol, 0.8% maleic anhydride, 2.5% adipic acid, 26.9% phthalic anhydride and 1% hypophosphorous acid into the reactor , raise the temperature to 155-160°C for 1 hour; within 2 hours, raise the temperature to 205°C and maintain, the gas phase drops below 80°C, add the reflux solvent butyl acetate 5.1% for reflux reaction, maintain reflux at 205°C, detect the solid acid value and viscosity, and reach After the index cools down;

[0026] b. Cool down to 175°C, then add 1.2% maleic anhydride, the raw material in a, keep the reaction at 165-175°C for 1 hour, check the acid value and viscosity index, cool to 110-115°C after passing, add 4.14% dipropylene glycol methyl ether Dilute to form a semi-finished product;

[0027] two-step reaction

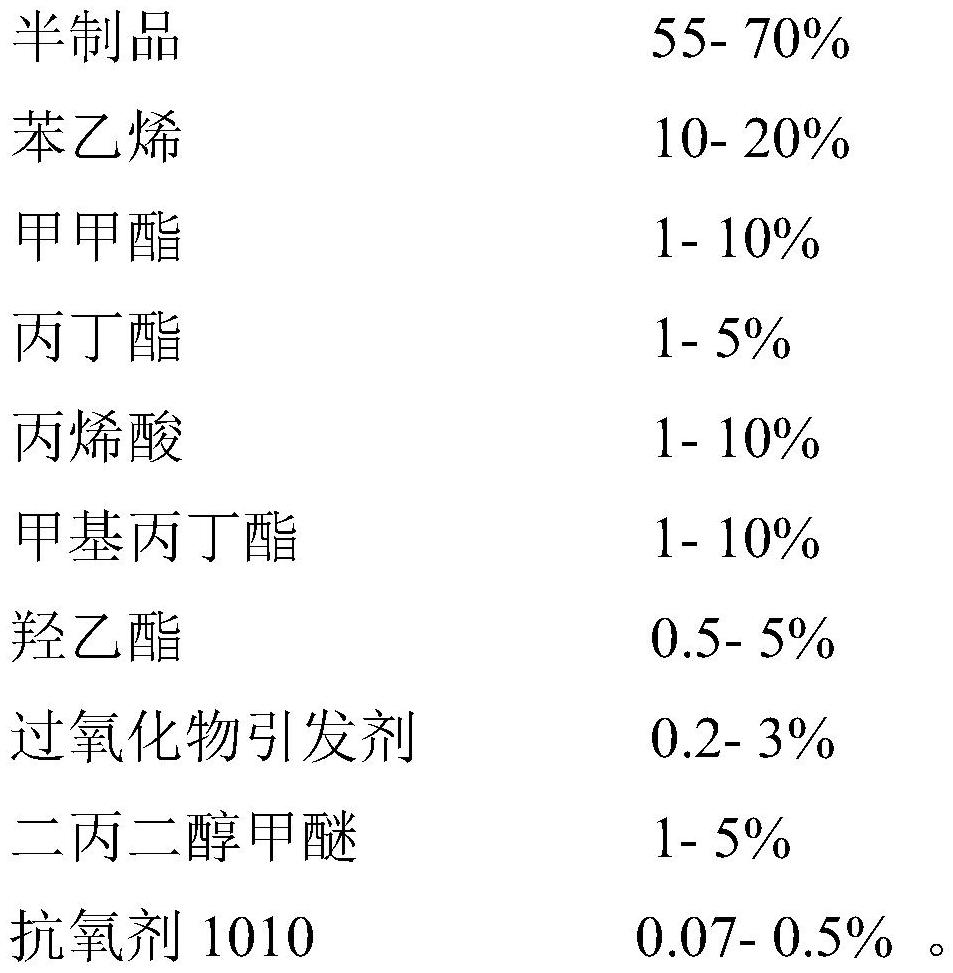

[0028] c. Put 62.9% of semi-finished products, 3% of dipropylene glycol methyl ether and 0.14% of antioxidant 1010 in...

Embodiment 2

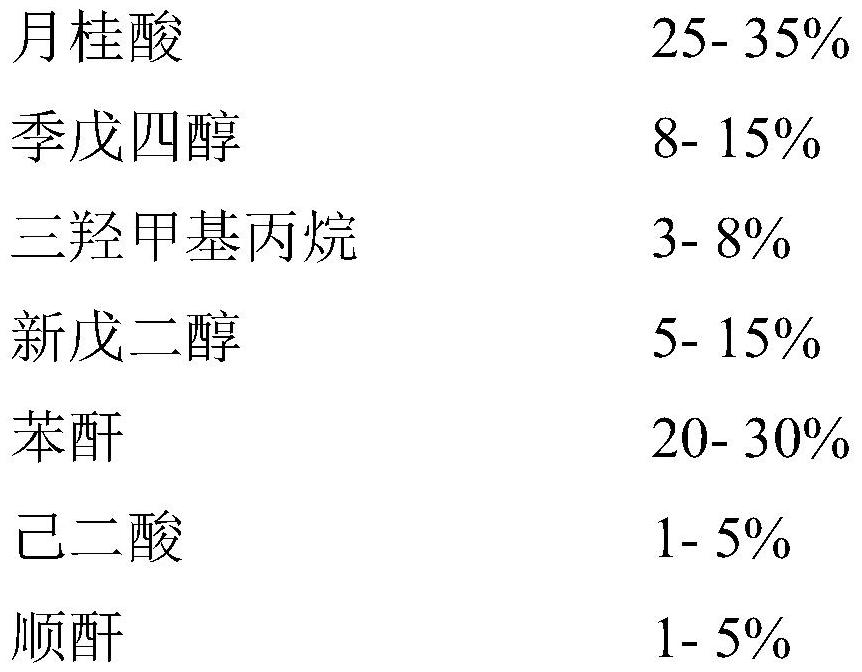

[0031] one step reaction

[0032] a. Add 28.4% lauric acid, 11.4% pentaerythritol, 7.6% trimethylolpropane, 9.96% neopentyl glycol, 1.5% maleic anhydride, 4.5% adipic acid, 27.2% phthalic anhydride and 1% hypophosphorous acid into the reactor , raise the temperature to 155-160°C for 1 hour, then raise the temperature to 205°C for 2 hours, then add the reflux solvent butyl acetate 5.1% for reflux reaction, and maintain the reflux at 205°C to detect the solid acid value and viscosity. After the index cools down;

[0033] b. Cool down to 175°C, then add 1.2% maleic anhydride as the raw material in a, keep the reaction at 165-175°C for 1 hour, check the acid value viscosity index, cool to 110-115°C after passing, add dipropylene glycol methyl ether 2.14 % diluted to form a semi-finished product;

[0034] two-step reaction

[0035] c. Put 59.9% of semi-finished products, 3% of dipropylene glycol methyl ether and 0.14% of antioxidant 1010 into the reactor, add 4.4% of acrylic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com