Waterborne two-component light-color in-tank electrostatic conduction anticorrosive paint and preparation method thereof

An anti-corrosion coating, two-component technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of carbon black in the paint film, restrictions on popularization and application, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

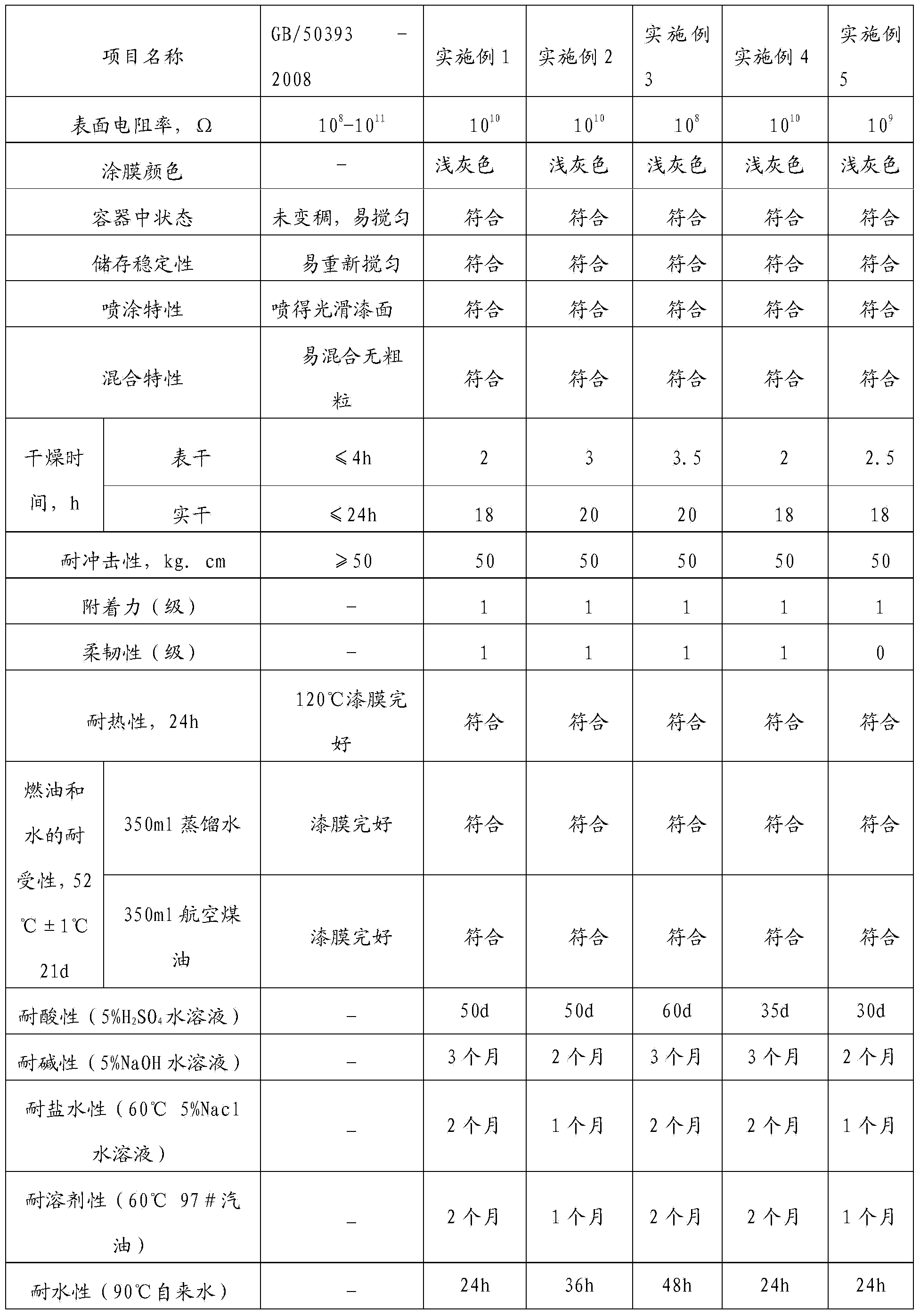

Embodiment 1

[0031] A water-based two-component light-colored anti-static anti-corrosion coating in a tank. Its components and mass percentages are as follows: 13.2% of tap water, 41% of water-based epoxy emulsion, 11% of water-based epoxy curing agent, 16.8% of light-colored conductive filler, 8% composite iron-titanium powder, 4% rutile titanium dioxide, 3% talc powder, 0.2% anti-settling agent, 0.2% wetting and dispersing agent A, 0.3% wetting and dispersing agent B, 1% film-forming aid, Anti-flash rust agent 0.1%, thickener 0.5%, defoamer A 0.2%, defoamer B 0.2%, leveling agent 0.3%. Its preparation method is as follows:

[0032] 1) Under the stirring condition of 400r / min, add 7.5% tap water, 0.2% wetting and dispersing agent A, 0.3% wetting Dispersant B, 0.5% film-forming aid, 0.2% defoamer A, stirred for 5 minutes; under stirring at 600r / min, add 0.2% anti-settling agent, 8% composite iron-titanium powder, 4% rutile titanium dioxide, 3% talc powder, then disperse at high speed for...

Embodiment 2

[0037] A water-based two-component light-colored anti-static anti-corrosion coating in a tank, its components and mass percentages are as follows: 20% of tap water, 30% of water-based epoxy emulsion, 7% of water-based epoxy curing agent, 18% of light-colored conductive filler, Composite iron-titanium powder 12.4%, rutile titanium dioxide 1%, barite powder 7%, anti-sedimentation agent 0.2%, wetting and dispersing agent A0.3%, wetting and dispersing agent B0.2%, film-forming aid 1.5% , Anti-flash rust agent 0.4%, thickener 1.2%, defoamer A0.3%, defoamer B0.3%, leveling agent 0.2%. Its preparation method is as follows:

[0038] 1) Under the stirring condition of 100r / min, add 10.3% tap water, 0.3% wetting and dispersing agent A, 0.2% wetting Dispersant B, 0.3% defoamer A, 0.75% film-forming aid, stirred for 5 minutes; under stirring at 800r / min, add 0.2% anti-settling agent, 12.4% anti-rust pigment, 1% titanium dioxide, 7% weight Spar powder, then disperse at high speed for 30 ...

Embodiment 3

[0043] A water-based two-component light-colored anti-static anti-corrosion paint in a tank, its components and mass percentages are as follows: 17% of tap water, 38% of water-based epoxy emulsion, 10% of water-based epoxy curing agent, 9% of light-colored conductive filler, 15% flaky mica powder, 1.5% rutile titanium dioxide, 6% barite powder, 0.1% anti-sedimentation agent, 0.3% wetting and dispersing agent A, 0.2% wetting and dispersing agent B, 1% film-forming aid , Anti-flash rust agent 0.6%, thickener 1%, defoamer A0.1%, defoamer B0.1%, leveling agent 0.1%. Its preparation method is as follows:

[0044] 1) Under the stirring condition of 300r / min, add 10.3% tap water, 0.3% wetting and dispersing agent A, 0.2% wetting Dispersant B, 0.1% defoamer A, 0.5% film-forming aid, stirred for 5 minutes; under stirring at 700r / min, add 0.1% anti-settling agent, 15% anti-rust pigment, 1.5% titanium dioxide, 6% weight Spar powder, then disperse at a high speed for 30 minutes at a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com