Conductive epoxy resin lawn pigment and coating process thereof

A technology of epoxy resin and floor coatings, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of failing to meet the requirements of conductive type, oil resistance, poor decoration, unstable conductive effect, etc., and achieve static conductive Excellent effect, smooth surface, beneficial to industrial production and popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

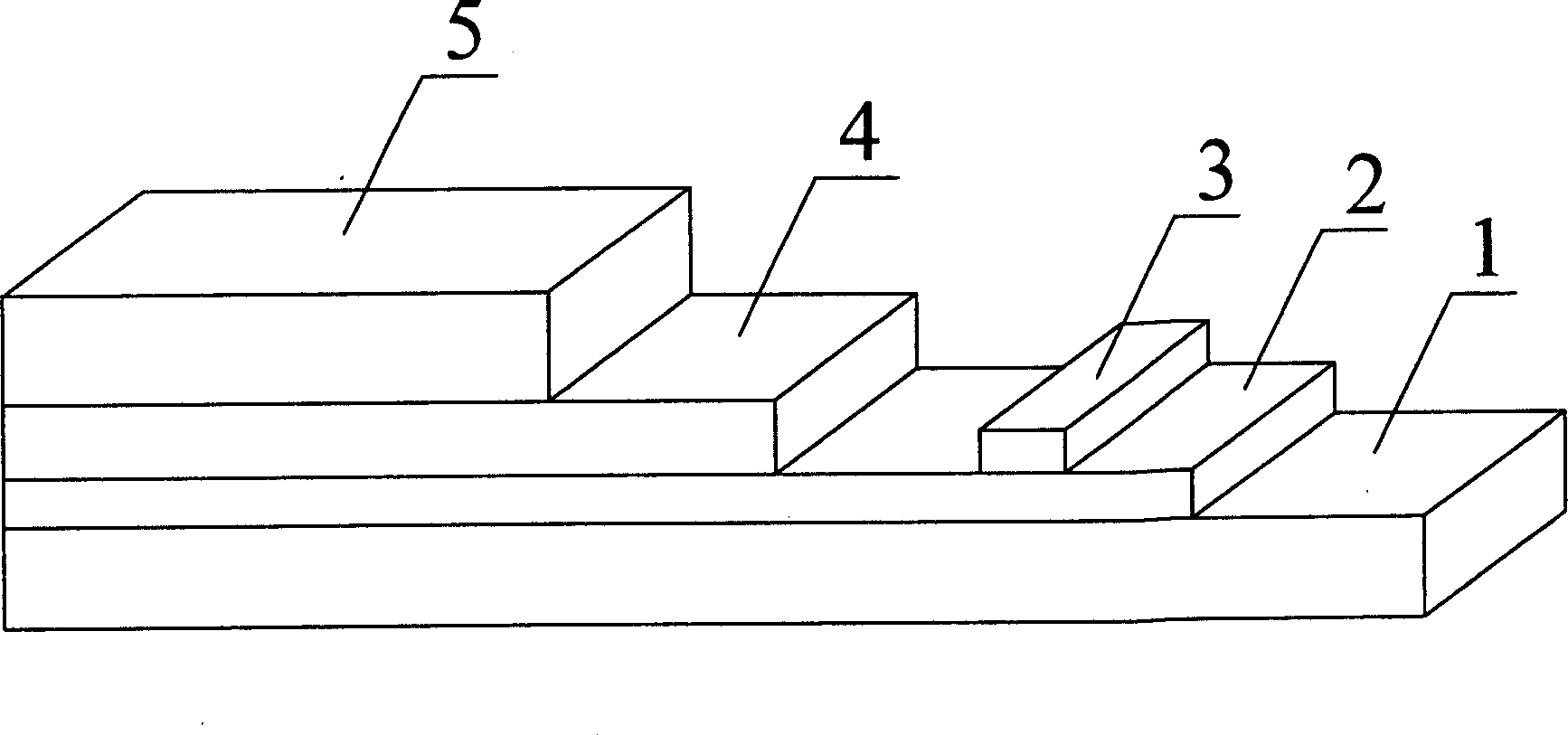

Method used

Image

Examples

Embodiment 1

[0053] The formula is: topcoat component A: epoxy resin E-51 55%, titanium dioxide 3%, chromium oxide green 2%, quartz powder 18%, active diluent AGE 6%, inactive toughening diluent phthalate Dibutyl formate 2%, benzyl alcohol 2%, wetting and dispersing agent EFKA4010 0.5%, rheology agent BYK4050.1%, defoamer EFKA2720 0.6%, leveling agent PERENOL F60 0.8%, conductive short fiber pulp 10%; Primer A component: epoxy resin E-44 55%, xylene 10%, n-butanol 10%, conductive graphite powder 25%. After the product is obtained according to the above-mentioned production process, the surface of the insulating asbestos board substrate is coated according to the above-mentioned coating process. After the paint film is cured, the surface is smooth and beautiful, without floating color, blooming, bubbles and swirls. After 48 hours, the surface resistance of the sample is 7×10 4 Ω, the volume resistance is 5×10 4 Ω, in line with industry standard SJ / T11294-2003.

Embodiment 2

[0055] The floor of the workshop on the first floor of a microelectronics factory is painted with the electrostatic conductive epoxy resin floor paint and the painting process of the present invention. The production list of topcoat component A is: epoxy resin E-51 550Kg, titanium dioxide 30Kg, chromium oxide green 20Kg, quartz powder 180Kg, active diluent AGE 60Kg, inactive toughening diluent dibutyl phthalate 20Kg , Benzyl alcohol 20Kg, wetting and dispersing agent EFKA4010 5Kg, rheology agent BYK405 1Kg, defoamer EFKA2720 6Kg, leveling agent EFKA3777 8Kg, conductive short fiber pulp 100Kg; Primer component A production list: epoxy resin E-44550Kg , xylene 100Kg, n-butanol 100Kg, conductive graphite powder 250Kg. After the product is obtained according to the above-mentioned production process, it is painted according to the above-mentioned coating process. After the paint film is cured, the surface is smooth and beautiful, without floating color, blooming, bubbles and swir...

Embodiment 3

[0057] The formula is: Topcoat A component: epoxy resin E-51 58%, titanium dioxide 2%, chromium oxide green 4%, heavy calcium carbonate 14%, active diluent AGE 5.5%, inactive toughening diluent o Dibutyl phthalate 2%, benzyl alcohol 1.5%, wetting and dispersing agent DEUCHEM904S 0.4%, rheological agent 4200-20 0.1%, defoamer DEUCHEM6800 0.7%, leveling agent L-1982 0.8%, conductive short fiber Slurry 11%; primer A component: epoxy resin E-44 50%, xylene 10%, n-butanol 10%, conductive graphite powder 30%. After the product is obtained according to the above-mentioned production process, the surface of the insulating asbestos board substrate is coated according to the above-mentioned coating process. After the paint film is cured, the surface is smooth and beautiful, without floating color, blooming, bubbles and swirls. After 48 hours, the surface resistance of the floor is 8×10 4 Ω, the volume resistance is 7×10 4 Ω, in line with industry standard SJ / T11294-2003.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com