Static-conducting connecting structure of coupling for double-layered pipes

A connection structure and electrostatic conduction technology, applied in the direction of pipeline connection layout, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient oil leakage detection, corrosion resistance, poor leakage resistance, safety accidents, etc., to achieve The effect of overcoming the damage of the conveying pipeline, good static conductivity, and reliable sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

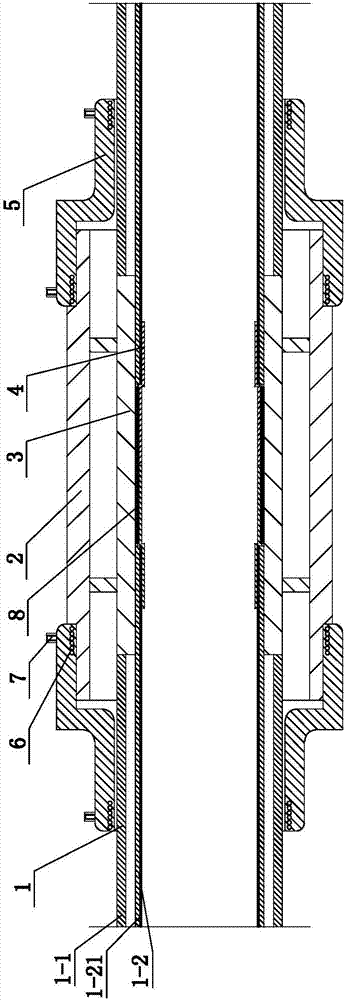

[0026] Such as figure 1 As shown, the present invention is used to connect a double-layer oil delivery pipeline 1 composed of an oil delivery outer pipe 1-1 and an oil delivery inner tube 1-2 whose inner wall is coated with a first electrostatic conductive layer 1-21, wherein the oil delivery inner tube 1-2 are used as delivery pipes for fuel oil.

[0027] The structure of the first embodiment: including the external connecting pipe 2 and the internal connecting pipe 3 connected to each other, the external connecting pipe 2 and the internal connecting pipe 3 are straight pipes, and the two ports of the internal connecting pipe 3 are respectively provided with static conductive materials. Made the plugin 4.

[0028] The plug-in 4 is in the shape of a tube, one end of the plug-in 4 is sealed in the inner connecting pipe 3, the oil delivery inner pipe 1-2 is sealed and sleeved on the other end of the plug-in 4, and the oil delivery outer tube 1-1 is set in the oil delivery inner...

no. 2 example

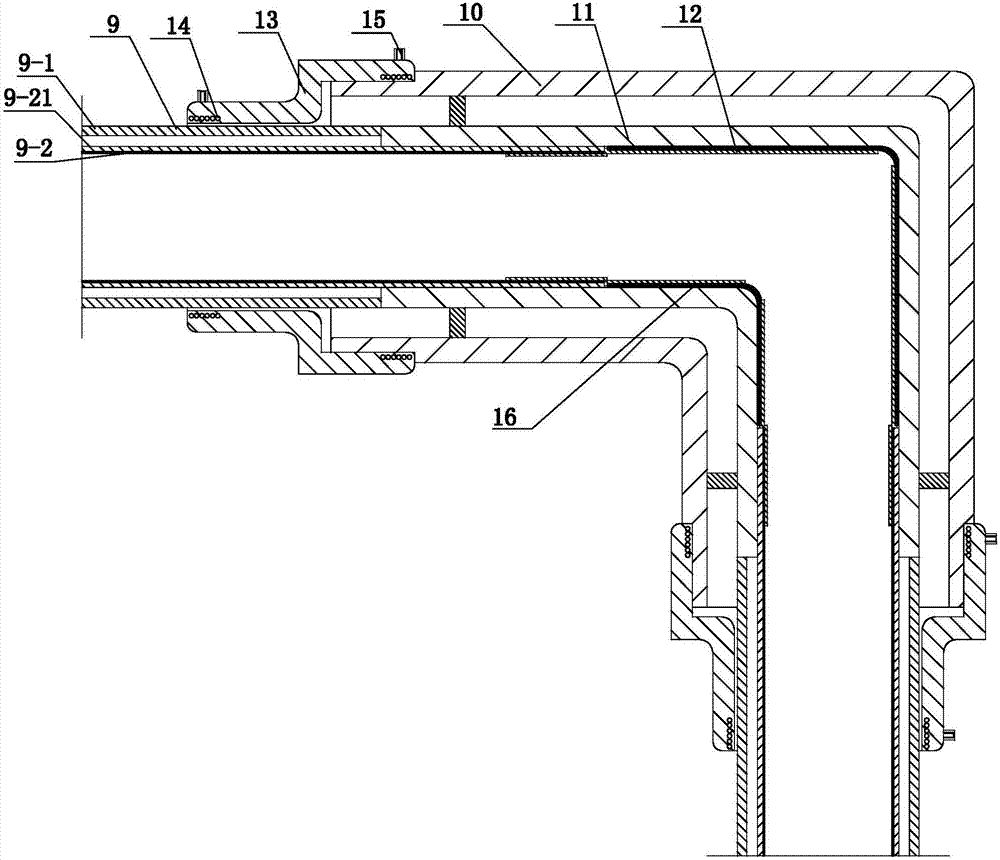

[0033] Such as figure 2 As shown, the present invention is used to connect the double-layer oil delivery pipeline 9 composed of the oil delivery outer pipe 9-1 and the oil delivery inner tube 9-2 whose inner wall is coated with the first electrostatic conductive layer 9-21, wherein the oil delivery inner tube 9-2 is used as the delivery pipe of fuel oil.

[0034] The structure of the second embodiment: including the external connecting pipe 10 and the internal connecting pipe 11 connected to each other, the external connecting pipe 10 and the internal connecting pipe 11 are all 90 ° elbows, and the two ports of the internal connecting pipe 11 are respectively provided with static electricity. Insert 12 made of conductive material.

[0035] The plug-in 12 is in the shape of a tube, one end of the plug-in 12 is sealed and sleeved in the inner connecting pipe 11, the oil delivery inner pipe 9-2 is sealed and sleeved on the other end of the plug-in 12, and the oil delivery outer...

no. 3 example

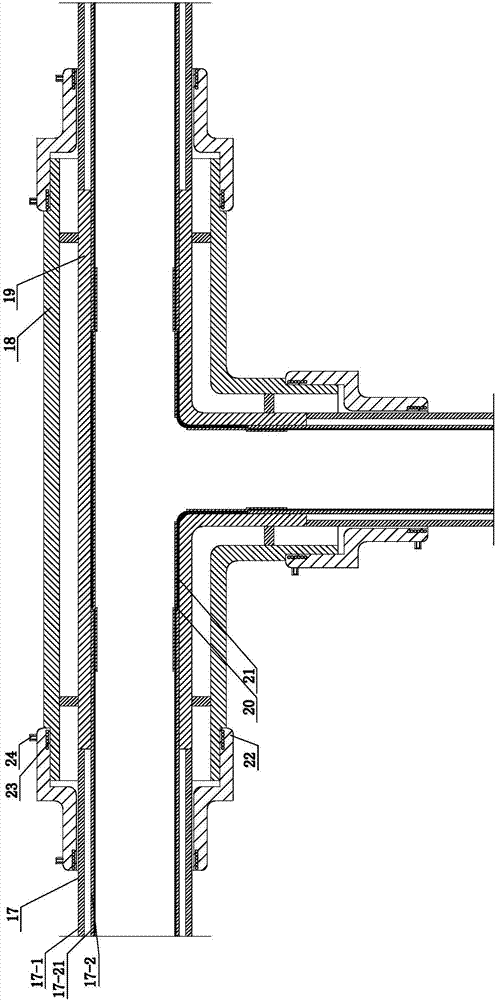

[0040] Such as image 3 As shown, the present invention is used to connect a double-layer oil delivery pipeline 17 composed of an oil delivery outer pipe 17-1 and an oil delivery inner tube 17-2 whose inner wall is coated with a first electrostatic conductive layer 17-21, wherein the oil delivery inner tube 17-2 is used as the delivery pipe of fuel oil.

[0041] The structure of the third embodiment: including the external connecting pipe 18 and the internal connecting pipe 19 connected to each other. Insert 20 made of conductive material.

[0042]The plug-in 20 is in the shape of a tube, one end of the plug-in 20 is sealed and sleeved in the inner connecting pipe 19, the oil delivery inner pipe 17-2 is sealed and sleeved on the other end of the plug-in 20 respectively, and the oil delivery outer tube 17-1 is sleeved in the oil delivery Outside the pipe 17-2, there is a gap between them to form a double-layer oil delivery pipeline 17. At the same time, the 360 ° penetratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com