Heavy corrosion resistant, heat insulating and static conductive coating

It is a static conductive and heavy-duty anti-corrosion technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc. It can solve problems such as human health damage, fire safety hazards, environmental pollution, etc., achieve strong adhesion, reduce coating costs, The effect of excellent shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

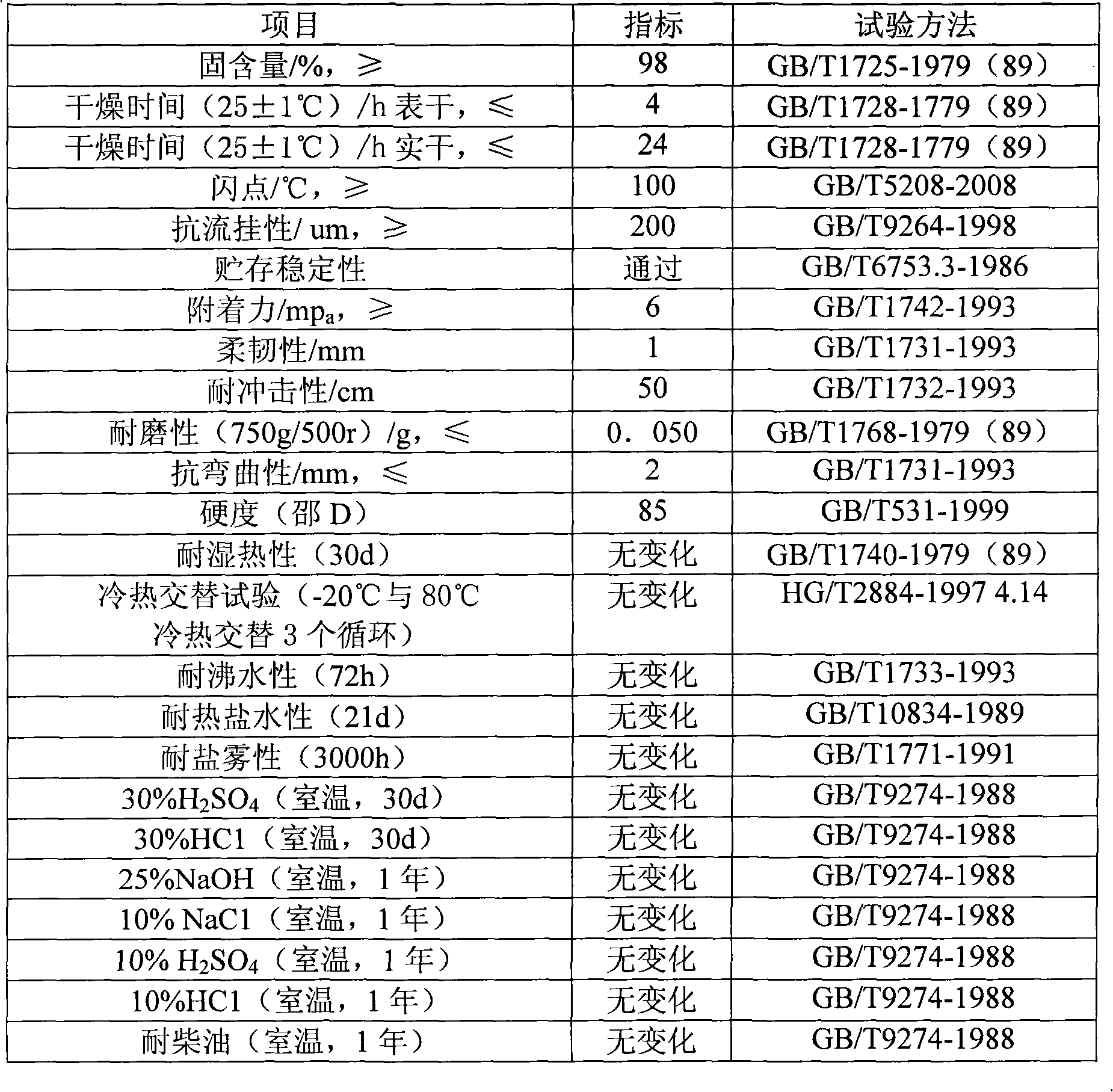

[0042] Example: A heavy-duty anti-corrosion heat-insulating and static-conductive coating: using acrylic modified epoxy resin as the base material, using reactive and non-reactive diluents as solvents, and using liquid polysulfide rubber as a toughening agent, in functional pigments and fillers Prepare component A with the cooperation of auxiliary agents; use modified amine synthesized from cashew nut shell liquid as curing agent, and form component B with the cooperation of accelerator and hydrophilic agent. After mixing components A and B at a weight ratio of 2:1 , formulated into a two-component heavy-duty anti-corrosion, heat-insulating, and static-conductive coating: the composition of each component in the formula is as follows, of which component A is:

[0043] Modified epoxy resin BYD-7201 40%

[0044] Polysulfide rubber JLY-121 2%

[0045] Reactive diluent 6286 5%

[0046] Non-reactive diluent NX-2020 10%

[0047] Ultrafine silica-alumina-based hollow microspheres ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com