High voltage discharge processing device for metal foil surface treatment

A high-voltage discharge and surface treatment technology, which is applied to the surface coating device, surface pretreatment, electrode manufacturing, etc., can solve the problem of affecting the electrical parameters of the pole piece, the metal foil adhesion is not strong, and the fast wide width cannot be realized. Problems such as double-sided sleeve coating to achieve the effect of reducing battery internal resistance, reducing thermal effects, and reducing the increase in dynamic internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

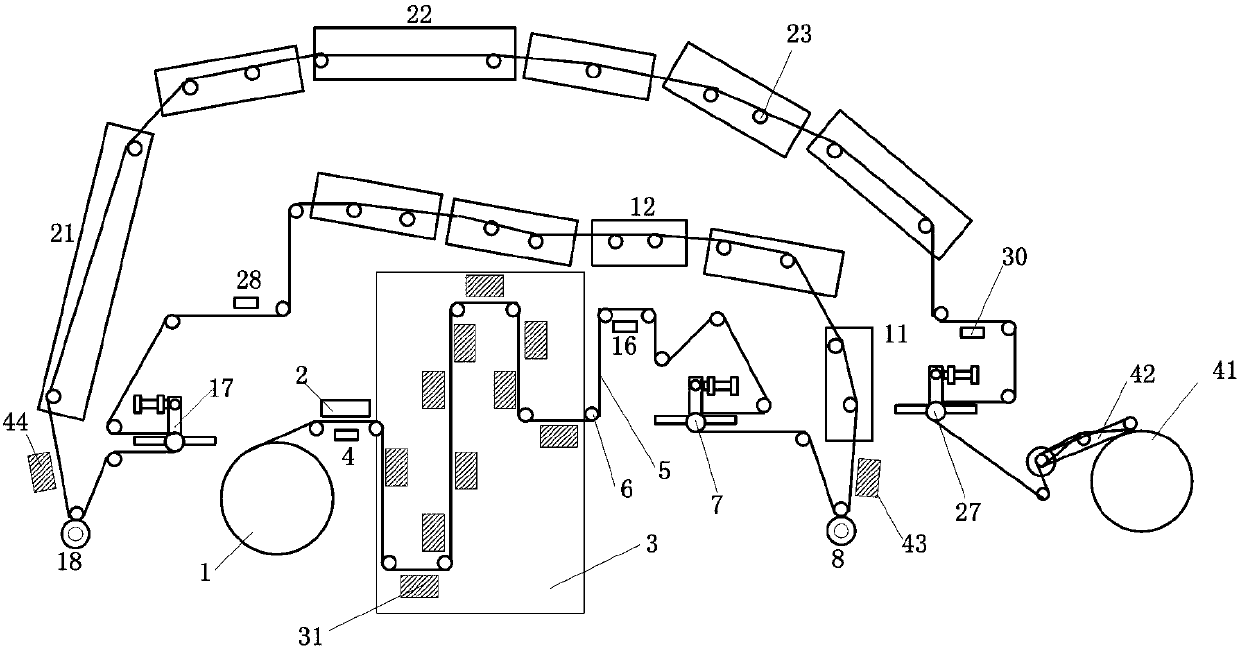

[0031] The present invention will be described in detail below by taking a wide-width pole piece double-sided sleeve coating machine for power batteries / supercapacitors as an example.

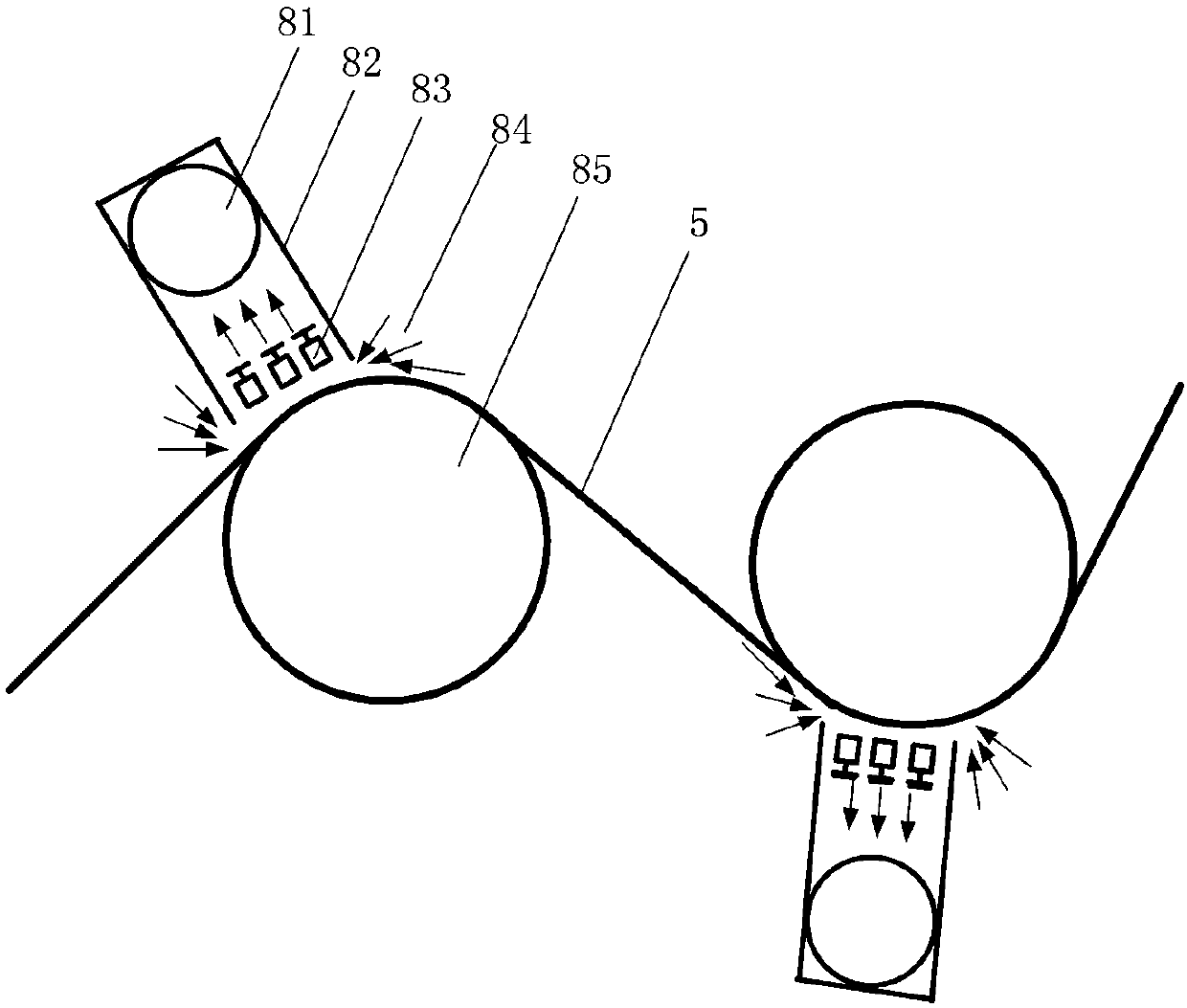

[0032] The double-sided sleeve coating machine for wide-width pole pieces for power batteries / supercapacitors is to coat the dispersed nano-conductive graphite and carbon-coated particles uniformly and delicately, with the positions of the front and back sides corresponding, and one-time coating on aluminum foil or copper foil , In high-energy storage equipment such as large-capacity power batteries and super capacitors, especially power batteries / supercapacitors that require short charging time, large power storage capacity, and long cycle life have made a leap in technology.

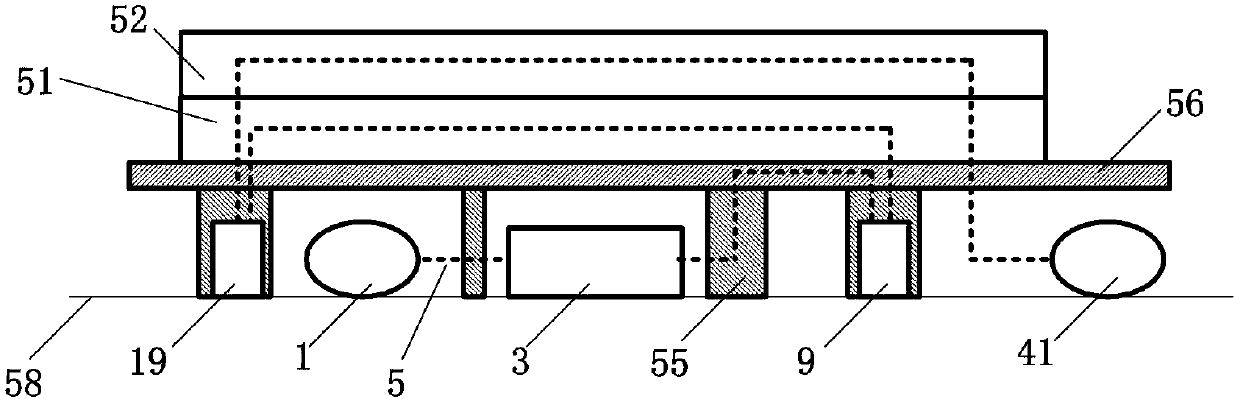

[0033] Such as figure 1 As shown, the coating machine of the present invention includes a lower drying tunnel 51 arranged above the frame structure, an upper drying tunnel 52 and an unwinding unit arranged below the fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com