Wide-breadth pole piece two-sided position-sleeving coating machine for power battery and supercapacitor

A technology for supercapacitors and power batteries, which is applied in the manufacture of battery electrodes, hybrid/electric double-layer capacitors, and devices for coating liquid on the surface. Problems such as fast wide width and double-sided sleeve coating can achieve the effect of reducing battery internal resistance, reducing thermal effect, and reducing cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

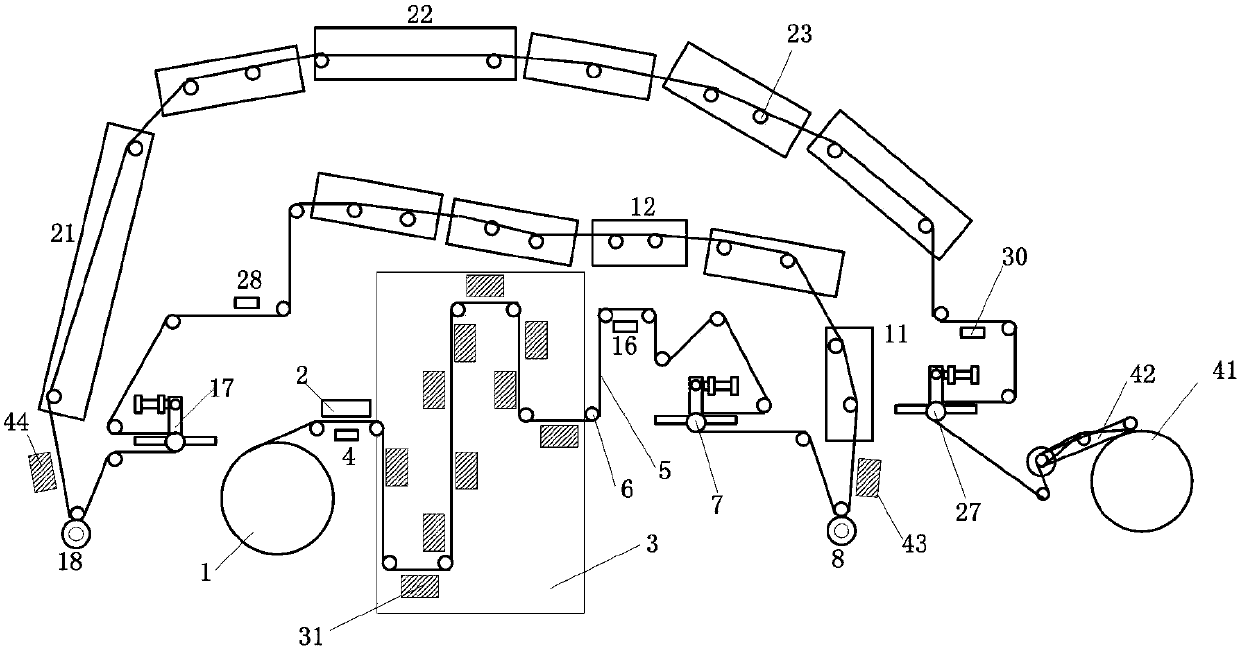

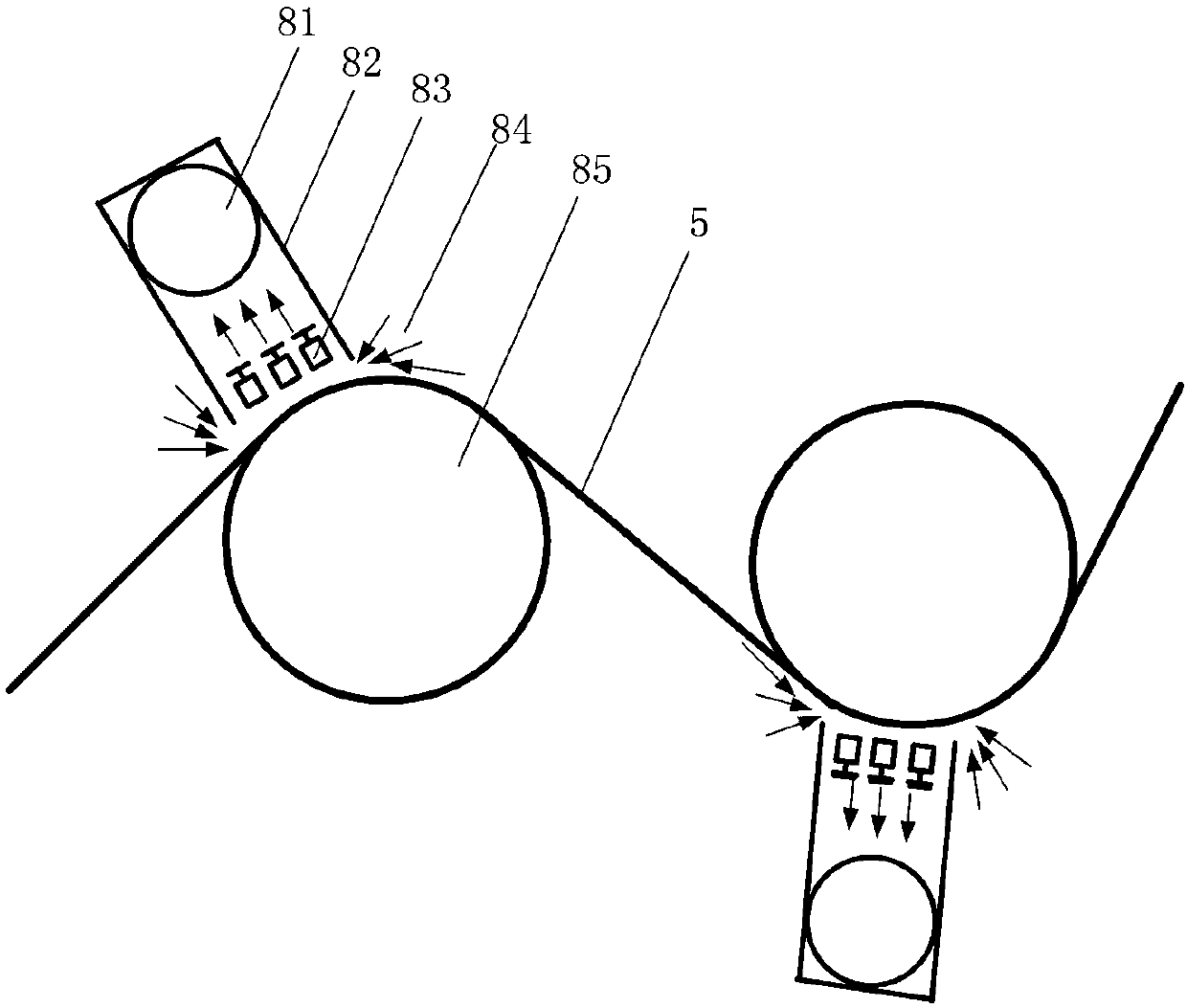

[0035] The wide-width pole piece double-sided sleeve coating machine for power batteries and supercapacitors is to coat the dispersed nano-conductive graphite and carbon-coated particles uniformly and delicately, with the front and back sides corresponding, and one-time coating on aluminum foil or copper foil , In high-energy storage equipment such as large-capacity power batteries and super capacitors, especially power batteries and super capacitors that require short charging time, large power storage capacity, and long cycle life, there has been a dramatic technological improvement.

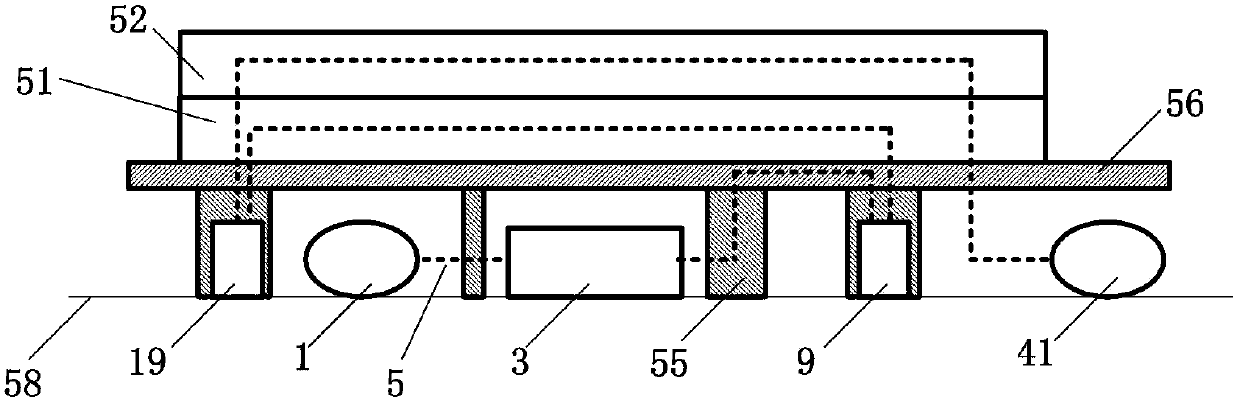

[0036] Such as figure 1 As shown, the coating machine of the present invention includes a lower drying tunnel 51 arranged above the frame structure, an upper drying tunnel 52 and an unwinding unit arranged below the frame structure, a winding unit, a high-voltage discharge treatment device 3, and a front coating device 9 and the reverse side coating device 19, the frame structure includes a st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com