Anti-flaming static electricity conducting organic silicon nano ceramic coating used for coal-mine gas drainage pipeline

A nano-ceramic, coal mine gas technology, applied in conductive coatings, pipeline protection, anti-corrosion coatings, etc., can solve the problems of poor anti-static, flammable, low mechanical strength of protective coatings, etc., to achieve high surface energy, improve corrosion resistance. , Outstanding effect of conducting static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

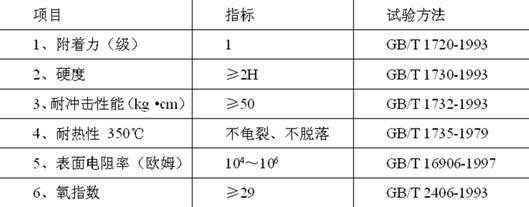

Image

Examples

Embodiment 1

[0030] 30 parts of pure silicone resin (purchased from Zhonghao Chenguang Chemical Research Institute), 15 parts of zinc phosphate, 10 parts of silicon carbide (particle diameter, that is, particle size 50-100nm), 25 parts of mica powder, 7 parts of graphite, organic bentonite (Purchased from Liupanshui Shenyuan Mining Co., Ltd.) 2 parts were mixed with 11 parts of solvent xylene, and ground on a sand mill for 2 hours to obtain a flame-retardant and electrostatically conductive coating.

[0031] How to use: Spray the paint on the surface of the pipe, and treat it at 300°C for 2 hours after the surface is dry to form a coating.

Embodiment 2

[0033] Mix 20 parts of pure silicone resin, 13 parts of zinc phosphate, 7 parts of aluminum oxide (particle size 50-300nm), 30 parts of talcum powder, 5 parts of graphite, 1 part of organic bentonite and 24 parts of solvent toluene. Grind on a sand mill for 2.5 hours to obtain a flame retardant and static conductive coating.

[0034] How to use: Spray the paint on the surface of the pipe, and treat it at 350°C for 40 minutes after the surface is dry to form a coating.

Embodiment 3

[0036] 40 parts of pure silicone resin, 10 parts of zinc phosphate, 5 parts of silicon dioxide (particle size 50-300nm), 10 parts of kaolin, 8 parts of conductive carbon black, fumed silica (purchased from Jining Qingyun Chemical Co., Ltd.) 3 1 part is mixed with 24 parts of solvent xylene, and ground on a pin-type sand mill for 2 hours to obtain a flame-retardant and static-conductive coating.

[0037] How to use: Spray the paint on the surface of the pipe, and treat it at 320°C for 70 minutes after the surface is dry to form a coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com