Super-weatherproof heavy-duty high-solid thermal insulating electrostatic conducting coating system

A heavy-duty, high-solid technology, used in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as poor weather resistance and lack of electrostatic conductivity, achieve good wear resistance, excellent thermal insulation effect, and reduce metal surface. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

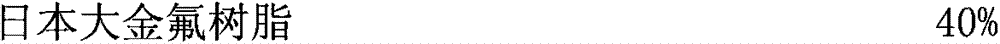

[0018] Example: A super weather-resistant heavy-duty anti-corrosion high-solid heat-insulating and electrostatically conductive coating system, including a bottom coating, an intermediate coating and a surface coating. The bottom coating is coated with an epoxy zinc-rich primer, and the intermediate coating The first layer is coated with epoxy mica iron oxide paint, and the surface coating is coated with fluorocarbon topcoat.

[0019] a. The composition of the epoxy zinc-rich primer is as follows,

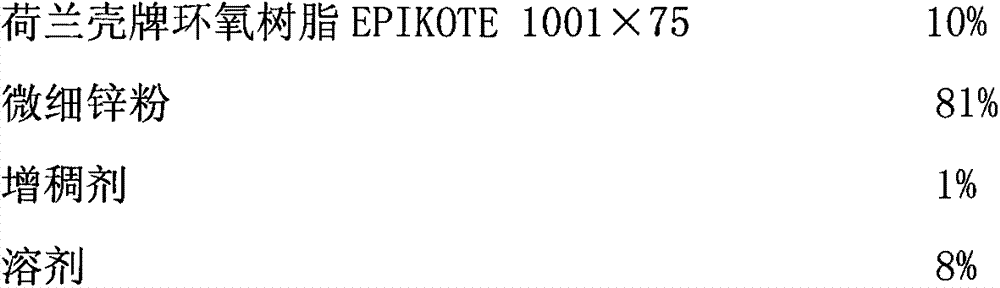

[0020] A component:

[0021]

[0022] Wherein, the thickener is organic bentonite and hydrogenated castor oil, and the solvent is mixed by trimethylbenzene, n-butanol and xylene;

[0023] B component:

[0024] Polyamide 56.8%

[0025] Solvent 43.2%

[0026] Wherein the solvent is formed by mixing trimethylbenzene and n-butanol;

[0027] A component and B component are mixed according to the volume ratio of 4:1.

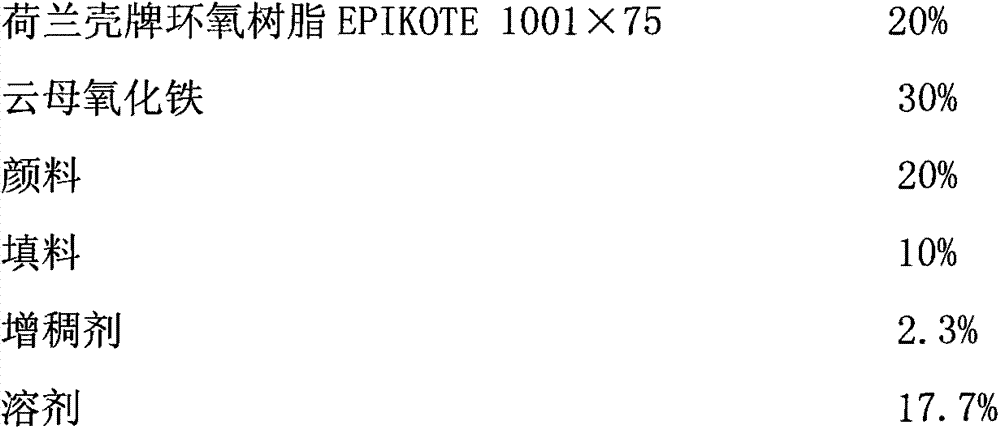

[0028] b. The composition of epoxy mica iron oxide paint is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com