Primer-topcoat type epoxy zinc powder coating and preparation method thereof

An epoxy zinc, bottom surface technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., to reduce the variety of coatings, avoid cumbersome processes, and improve the effect of decorative appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

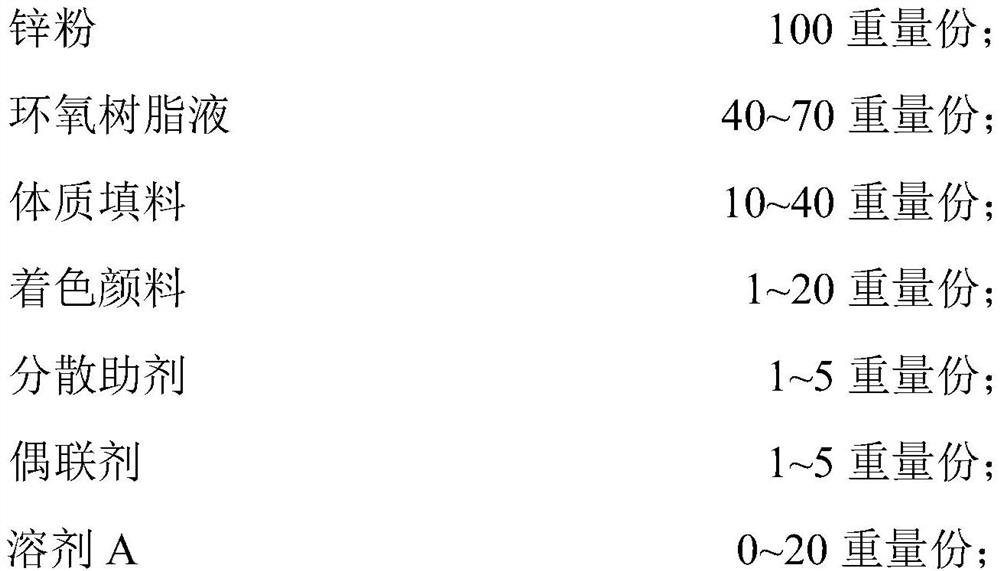

[0094] The composition of component A is as follows:

[0095] Taking zinc powder as 100 parts by weight,

[0096]

[0097]

[0098] Wherein epoxy 601 resin liquid (mass concentration 50%) is made by mixing epoxy 601 resin and solvent C with a mass ratio of 1:1; solvent A and solvent C are xylene: cyclohexanone: ethylene glycol butyl A mixed solvent with a mass ratio of ether of 1:0.5:0.5;

[0099] The preparation method of component A: add epoxy 601 resin liquid, red powder, dispersing aid, coupling agent and solvent according to the stated formula into the stirring container, and stir for 10 minutes until uniform at a speed of 800r / min; add body filler, Stir for 10 minutes until uniform; use a sand mill to grind to a fineness of less than 50 microns; under stirring, add the 500-mesh zinc powder of the formula, the speed is 1500r / min, stir for 30 minutes until uniform, filter through a filter, measure and pack, Obtain the A component.

[0100] The formula composition ...

Embodiment 2

[0116] The composition of component A is as follows:

[0117] Taking zinc powder as 100 parts by weight,

[0118]

[0119] Wherein epoxy 601 resin liquid (mass concentration 50%) is made by mixing epoxy 601 resin and solvent C with a mass ratio of 1:1; solvent A and solvent C are xylene: cyclohexanone: ethylene glycol butyl A mixed solvent with a mass ratio of ether of 1:0.5:0.5;

[0120] Preparation method of component A: add epoxy 601 resin solution, phthalocyanine blue, dispersing aid, coupling agent and solvent according to the stated formula into the stirring container, and stir for 10 minutes until uniform at a speed of 800r / min; add body filler , stir for 10 minutes until uniform; use a sand mill to grind to a fineness of less than 50 microns; under stirring, add the 500-mesh zinc powder of the formula, the speed is 1500r / min, stir for 30 minutes until uniform, filter through a filter, measure and pack , to obtain component A.

[0121] The formula composition of B...

Embodiment 3

[0137] Taking zinc powder as 100 parts by weight,

[0138]

[0139]

[0140] Wherein epoxy 604 resin liquid (mass concentration 50%) is made by mixing epoxy 601 resin and solvent C with a mass ratio of 1:1; solvent A and solvent C are xylene: the mass ratio of cyclohexanone is 1 : 0.5 mixed solvent;

[0141] Preparation method of component A: add epoxy 604 resin solution, phthalocyanine blue, dispersing aid, coupling agent and solvent according to the stated formula into the stirring container, and stir for 20 minutes until uniform at a speed of 1000r / min; add body filler , stir for 20 minutes until uniform; use a sand mill to grind to a fineness of less than 50 microns; under stirring, add the 800-mesh zinc powder of the stated formula at a speed of 2000r / min, stir for 30 minutes until uniform, filter through a filter, and measure and pack , to obtain component A.

[0142] The formula composition of B component is as follows:

[0143] Prepare the phenalkamine curing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com