Metal texture-simulated coating and preparation method thereof

A texture coating and metal imitation technology, applied in polyester coatings, polycarbonate coatings, metal-free paints, etc., can solve problems such as inability to produce metal effects, air pollution in the car, and easy residual monomers in coatings. High metal texture, excellent mechanical properties, high surface gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

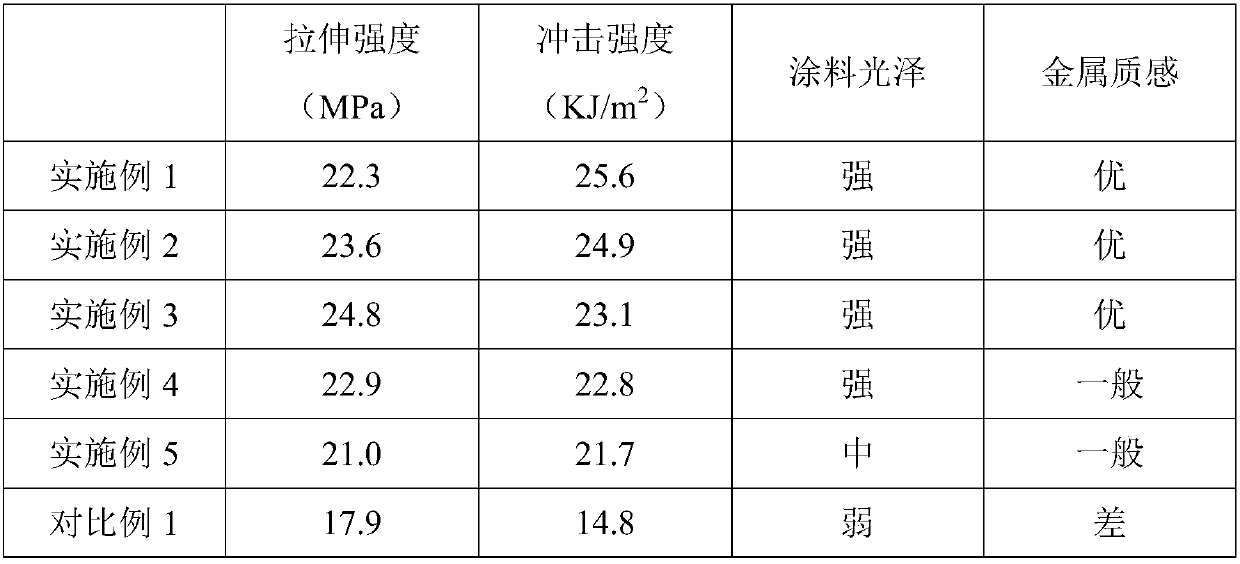

Examples

Embodiment 1

[0027] A metal-like texture paint, comprising the following parts by weight: 110 parts by weight of acrylic resin emulsion, 35 parts by weight of flake aluminum powder with a particle diameter of 10 microns, 18 parts by weight of talcum powder with a particle diameter of 30 microns, phosphite 4 parts by weight, 15 parts by weight of ethylene-propylene copolymer, 5 parts by weight of ethylene-octene copolymer grafted maleic anhydride, and 2 parts by weight of diethylenetriaminopropyltrimethoxysilane.

[0028] Wherein, the particle diameter of the flake metal pigment is 1-50 microns.

[0029] The preparation method of described imitation metallic texture paint, the steps are as follows:

[0030] (1) Add flake aluminum powder and ethylene-octene copolymer grafted maleic anhydride to acrylic resin emulsion, add diethylenetriaminopropyltrimethoxysilane, mix in a mixer for 50min, and then add talc powder , ultrasonically disperse at 60°C for 30 minutes, and then stand still for 40 ...

Embodiment 2

[0033] A metal-like texture paint, made of the following parts by weight: 120 parts by weight of polyethylene terephthalate emulsion, 40 parts by weight of flaky aluminum powder with a particle diameter of 50 microns, and 40 parts by weight of aluminum powder with a particle diameter of 35 microns 15 parts by weight of barium sulfate, 5 parts by weight of hindered phenolic antioxidant, 18 parts by weight of ethylene-octene copolymer, 3 parts by weight of ethylene-octene copolymer grafted maleic anhydride, aminoethylaminopropyl triethoxy 5 parts by weight of base silane.

[0034] The preparation method of described imitation metallic texture paint, the steps are as follows:

[0035] (1) Add flake aluminum powder and ethylene-octene copolymer grafted maleic anhydride to polyethylene terephthalate emulsion, add aminoethylaminopropyl triethoxysilane, and Mix in medium for 45 minutes, then add barium sulfate, ultrasonically disperse at 60°C for 30 minutes, and then stand still for...

Embodiment 3

[0038] A kind of imitation metallic texture paint, is made of following material by weight: polycarbonate latex 100 weight parts, particle diameter is 30 weight parts of flake copper powder of 5 micrometers, particle diameter is 20 weight parts of calcium carbonate of 40 micrometers, 3 parts by weight of benzophenones, 10 parts by weight of ethylene-octene copolymer, 6 parts by weight of polypropylene grafted maleic anhydride, and 1 part by weight of diethylenetriaminopropyltrimethoxysilane.

[0039] The preparation method of described imitation metallic texture paint, the steps are as follows:

[0040] (1) Add flake copper powder and polypropylene grafted maleic anhydride in the polycarbonate emulsion, add divinyltriaminopropyltrimethoxysilane, mix in the mixer for 60min, then add calcium carbonate, at 60 Ultrasonic dispersion at ℃ for 25 minutes, and then stand still for 35 minutes to obtain the mixed system 1;

[0041] (2) Add benzophenones and ethylene-octene copolymer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com