Production process and molding equipment for 3D (three-dimensional) battery cover

A molding equipment and manufacturing process technology, applied in the direction of battery cover/end cover, battery pack components, battery box/jacket, etc., can solve the problems of damaged molding surface, easily damaged battery cover, no bright effect, etc. The effect of high molding yield and improving surface brightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

[0031] The manufacturing process of a 3D battery cover of the present invention is achieved through the following steps:

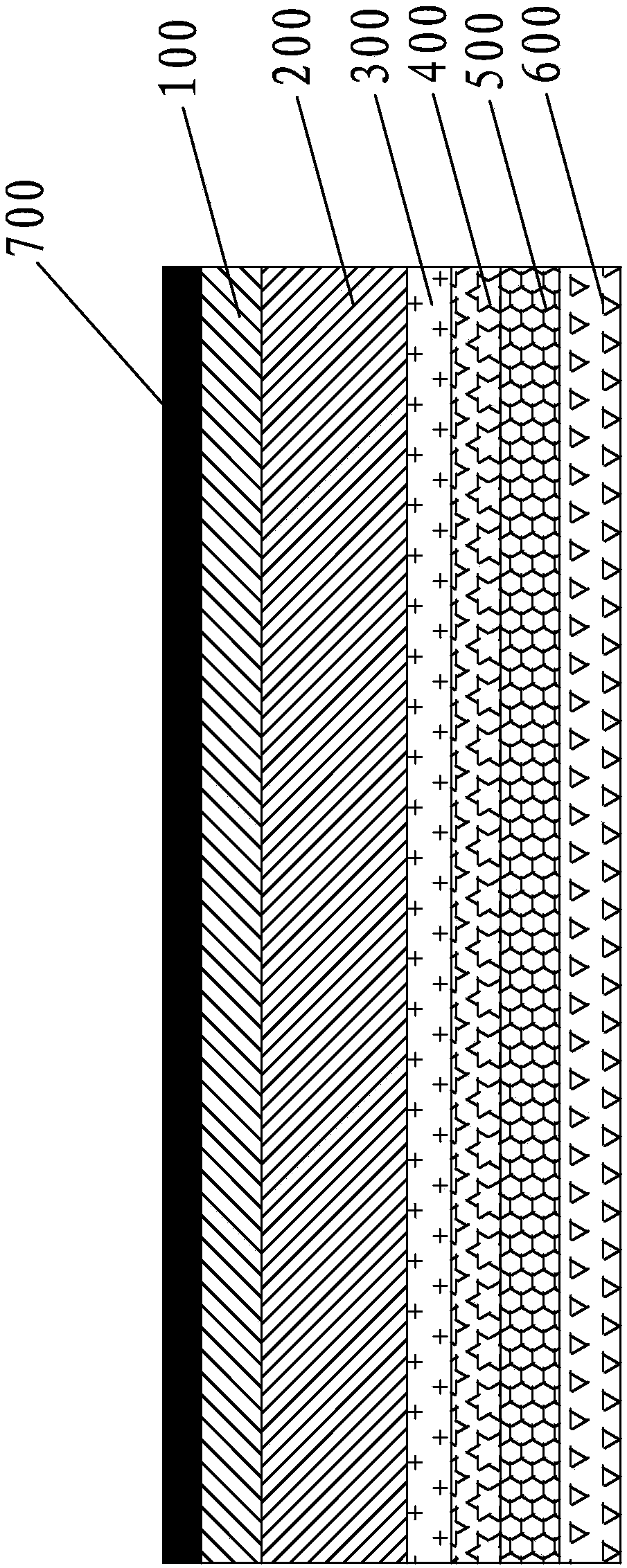

[0032] 1. Sheet composite, such as figure 1 As shown, the PMMA film 100 and the PC film 200 are compounded together to form a composite board, and the thickness of the PMMA film 100 is thinner than the thickness of the PC film 200, the PMMA film 100 is above the PC film 200, and the two completely overlap;

[0033] 2. Printing: A LOGO pattern printing layer 300 is printed on the bottom surface of the PC film 200, and then a UV transfer texture pattern layer 400 is transferred on the LOGO pattern printing layer 300 by UV glue, that is, using UV glue and UV printing process The pattern printing layer 300 is printed with a pattern texture, such as a grating texture, and then an optical film layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com