A kind of solvent-free epoxy zinc-rich anticorrosion coating and preparation method thereof

An epoxy zinc-rich, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem that the surface of the coating is prone to pits, pinholes, orange peel, and the thickness of the coating film easily exceeds 150μm , poor storage stability of operational coatings, etc., to achieve excellent anti-corrosion performance, improve resource utilization efficiency, and improve the effect of isolation and shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

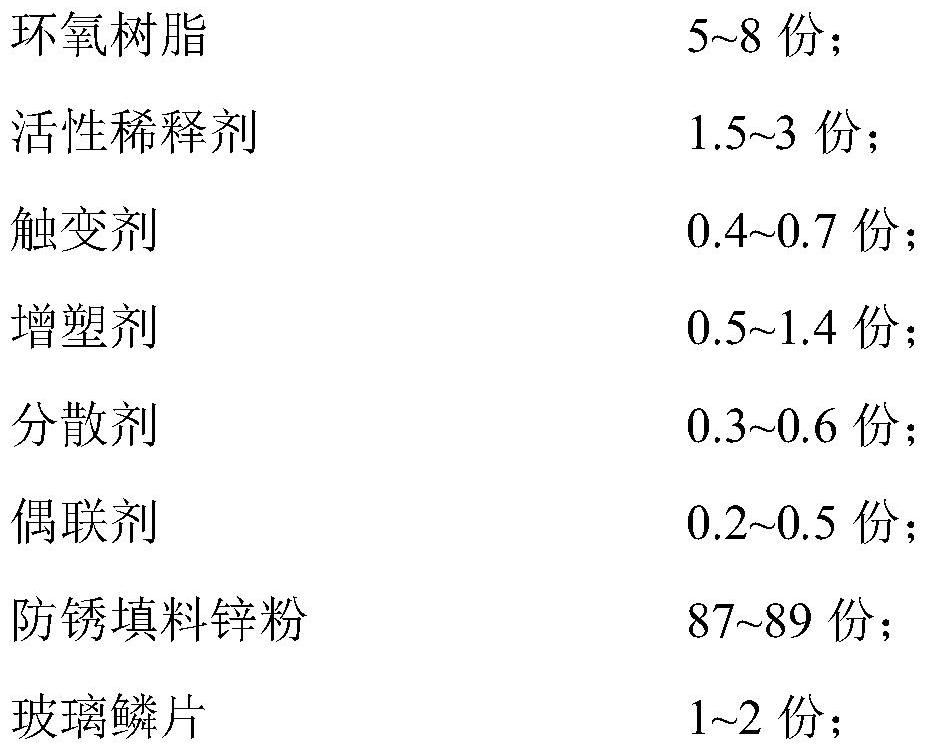

[0040] A solvent-free epoxy zinc-rich anti-corrosion coating, comprising A component and B component, wherein A component is calculated by weight, including:

[0041]

[0042] Component B includes the following components by weight fraction:

[0043] 4 parts of modified phenalkamine curing agent;

[0044] 1 part polyamide curing agent;

[0045] 0.25 parts of curing accelerator;

[0046] The weight ratio of component A to component B is 0.8:1; according to the weight ratio, component A and component B are mixed, stirred evenly and matured for 7-15 minutes before coating.

[0047] The specific preparation method is as follows:

[0048] ① Weigh the raw materials according to the above ratio, add the epoxy resin; then slowly add the active diluent, the stirring speed is 500-800r / min, and stir for 10-15 minutes;

[0049] ②Adjust the stirring speed to 800~1000r / min, add thixotropic agent and coupling agent during the stirring process, then keep stirring at 1000~2500 r / min, ke...

Embodiment 2

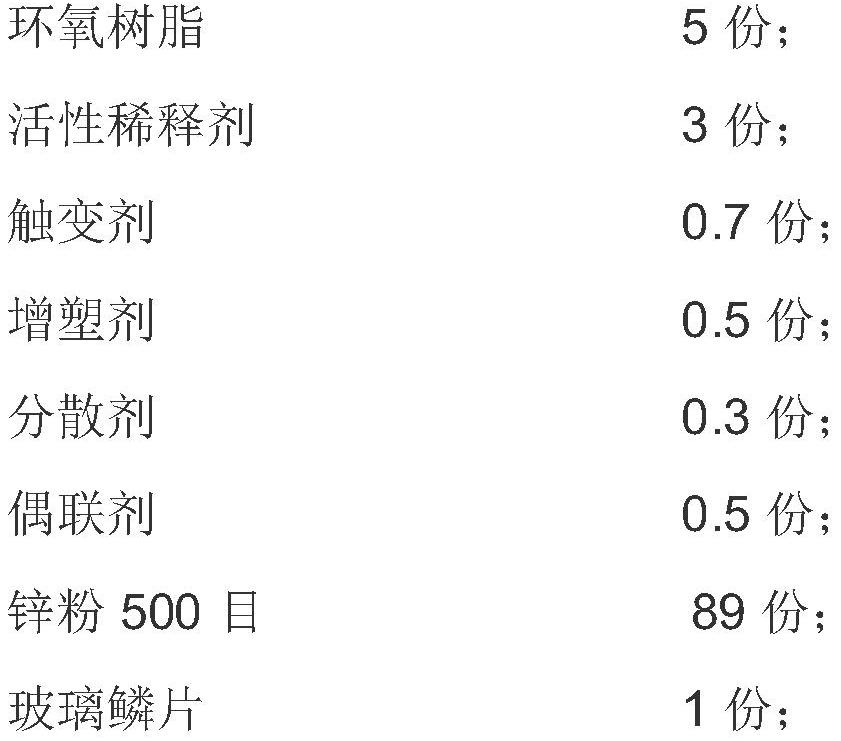

[0055] A solvent-free epoxy zinc-rich anti-corrosion coating, comprising A component and B component, wherein A component is calculated by weight, including:

[0056]

[0057] Contains the following B components by weight:

[0058] 2.5 parts of modified phenalkamine curing agent;

[0059] 2.5 parts of polyamide curing agent;

[0060] 0.4 parts of curing accelerator;

[0061] Preparation method: with embodiment 1.

[0062] The weight ratio of the A component to the B component is 1.2:1; according to the weight ratio, the A component and the B component are mixed, stirred and matured for 7 to 15 minutes before coating.

Embodiment 3

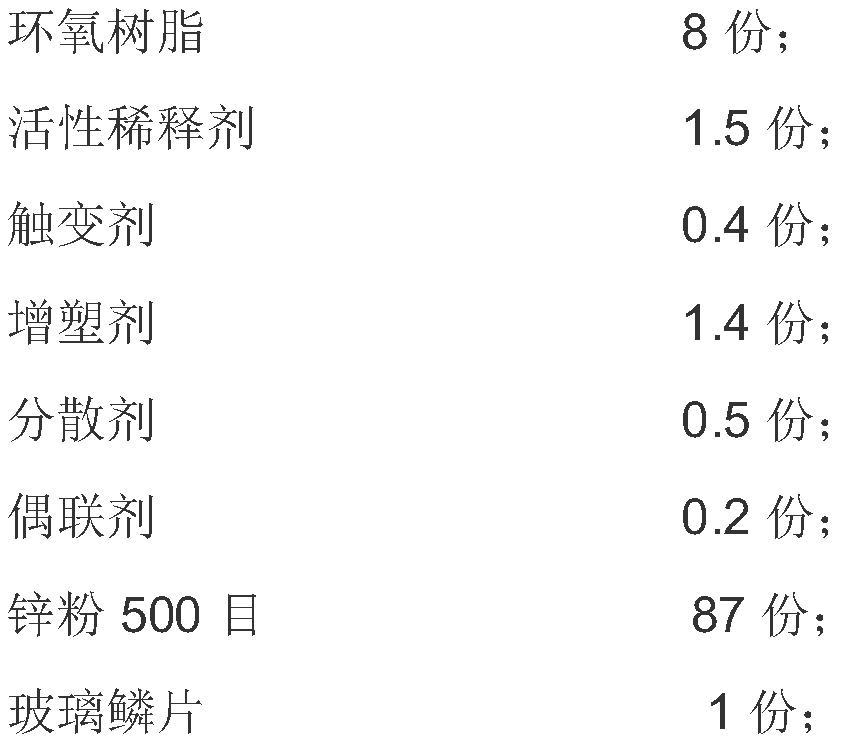

[0064] A solvent-free epoxy zinc-rich anti-corrosion coating, comprising A component and B component, wherein A component is calculated by weight, including:

[0065]

[0066] Contains the following B components by weight:

[0067] 2.5 parts of modified phenalkamine curing agent;

[0068] 2.5 parts of polyamide curing agent;

[0069] 0.3 parts of curing accelerator;

[0070] Preparation method: with embodiment 1.

[0071] The weight ratio of the A component to the B component is 0.95:1; according to the weight ratio, the A component and the B component are mixed, stirred evenly and matured for 7-15 minutes before coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com