Composition, rubber compound, preparation method of rubber compound and tire

A composition and compounding technology, applied in special tires, tire parts, transportation and packaging, etc., can solve other problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

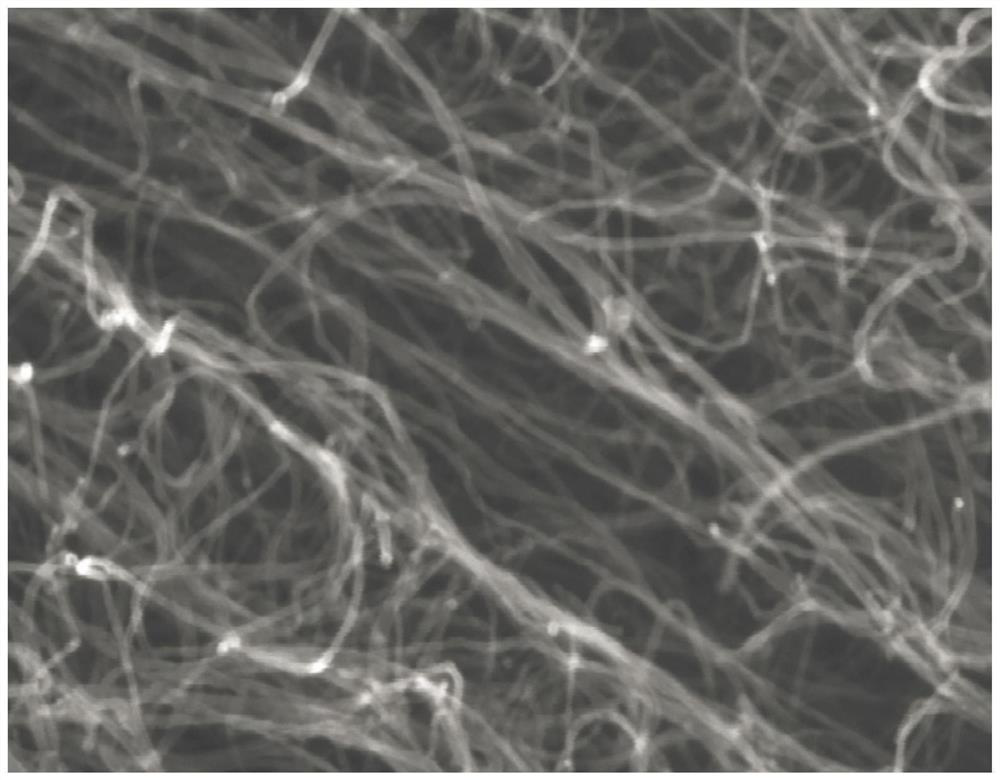

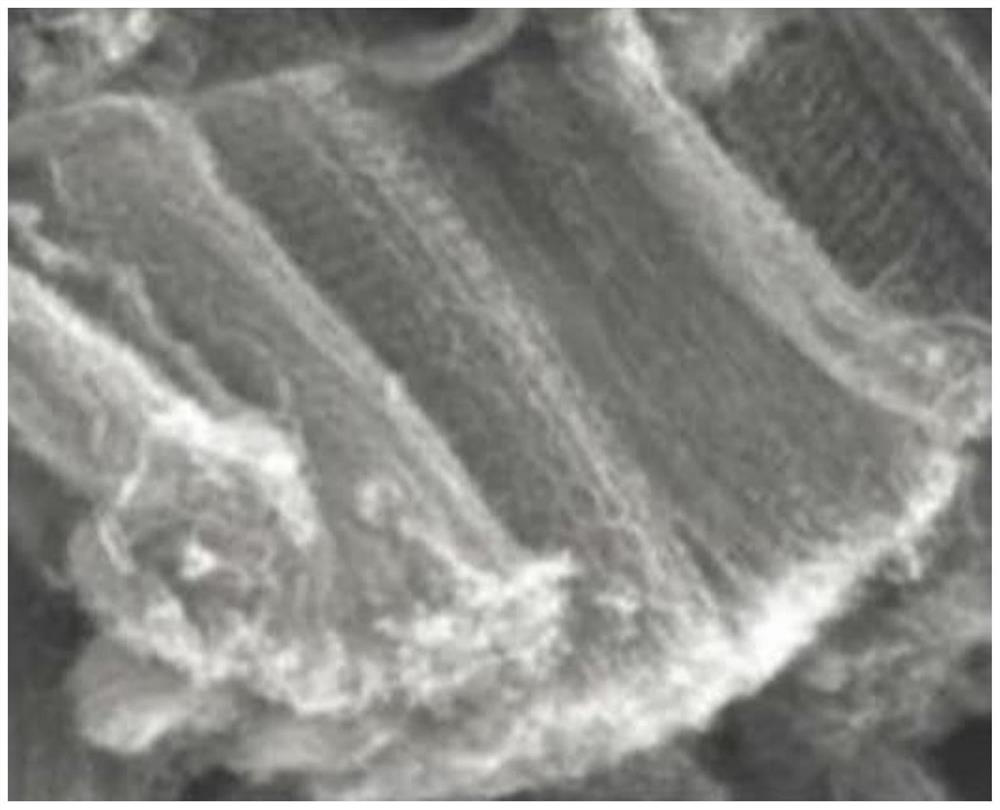

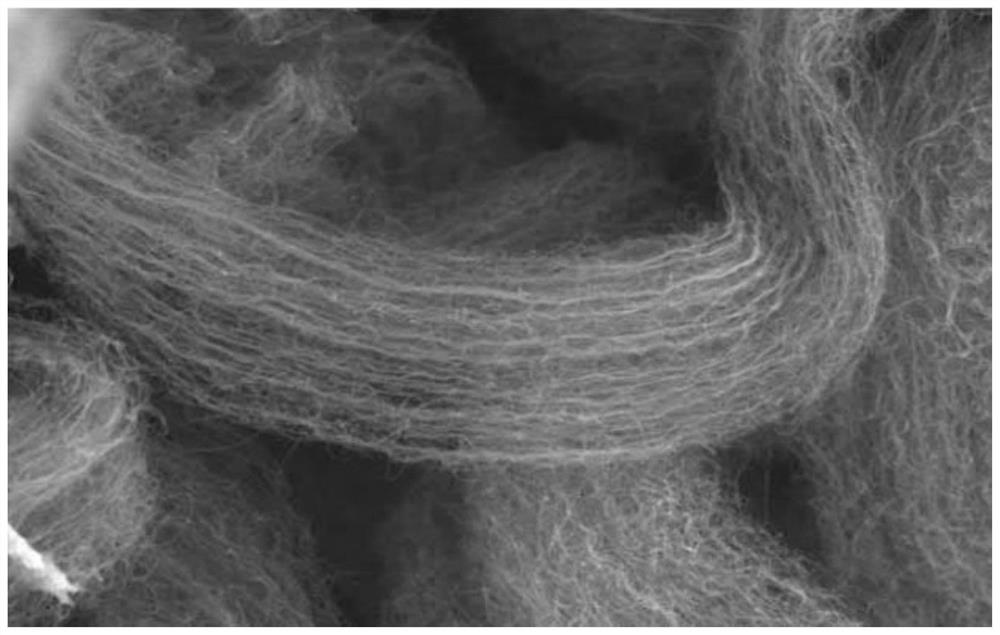

Image

Examples

preparation example Construction

[0086] The present application also provides a preparation method of rubber compound, which includes: one-stage mixing, two-stage mixing and three-stage mixing.

[0087] Among them, the one-stage mixing process includes: at 85rpm, first add 100 parts by weight of rubber to the internal mixer for mixing, lift the bolt at 40s, add 0-35 parts by weight of carbon black, 40-100 parts by weight of white rubber at 50s Mix carbon black (two-thirds of the amount) with 4 to 15 parts by weight of silane coupling agent, lift the plug at 110s, and add 20 to 50 parts of white carbon black (the remaining two-thirds of the amount) at 120s, 1 ~35 parts by weight of carbon nanotubes, 6~60 parts by weight of anti-wet skid resin, 0~35 parts by weight of liquid rubber, 0~6 parts by weight of tackifying resin, 3~4 parts by weight of zinc oxide, 1~2 parts by weight of stearin Acid, 2-10 parts by weight of processing aids and 0-30 parts by weight of process oil were mixed, cleaned in 180s, silanized ...

Embodiment 3

[0128] The formulations of Example 3 and Comparative Example 11 are shown in Table 7.

[0129] The formula of table 7 embodiment 3 and comparative example 11

[0130]

[0131]

[0132] The processing aid SL5044 was purchased from Tongcheng Huaqi Chemical;

[0133] Processing aid SL5044 is a mixture of fatty acid derivatives with different polarities:

[0134] The tackifying resin KORESIN was purchased from BASF;

[0135] The chemical formula of tackifying resin KORESIN is as follows:

[0136]

[0137] Among them, n is 7-8.

[0138] Protective wax SL10140 was purchased from Tongcheng Huaqi Chemical;

[0139] The formula of embodiment 3 and comparative example 11 is mixed according to the following method:

[0140] One stage of mixing: at 85rpm, first add 1 to the internal mixer for mixing, lift the bolt at 40s, add two-thirds of 5, 3 and 6 at 50s, mix, lift the bolt at 110s, add at 120s The remaining one-third of 5, 2, 4, 7, 8, 9, 11 and 12 were mixed, cleaned at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com