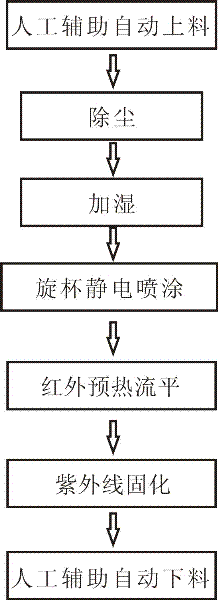

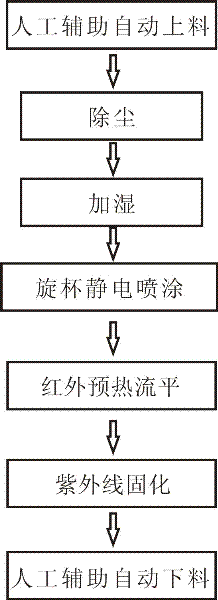

Production process of electrostatic coating on wooden doors

An electrostatic coating and production process technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problem that the corners of the wooden door leaf cannot be effectively coated, the coating environment has serious VOC pollution, and the wooden door is polished Problems such as high personnel density can improve the environment of the work area, reduce the number of polishing personnel and polishing workload, and improve the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Under the same film thickness requirements, the paint rate of the electrostatic rotary cup is 30%-45% higher than that of the air spray gun, which greatly reduces the waste of paint. When the waste of paint is more serious, the greater the waste paint, the disposal The more waste gas is produced, the greater the impact on the environment and energy use, that is, when the paint utilization rate increases by 30%-45%, the environmental pollution and energy consumption are relatively reduced by 30%-45% %; when spraying with electrostatic rotary cup, the paint film thickness error is between 5%-10%, while when using an air gun, it is between 20%-30%. The larger the film thickness error is, the worse the surface roughness of the workpiece will be. The workload during grinding is heavy and the dust generated will cause environmental pollution. On the contrary, the smaller the error of paint film thickness, the smaller the workload of grinding and the less dust generated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com