Novel environment protection ceramic interior wall paint and method for preparing the same

A technology of interior wall paint and enamel paint, applied in the direction of coating, etc., can solve the problems of high product cost, slow moisture absorption speed, which have not been seen yet, and achieve the effect of product cost reduction, fast moisture absorption speed, and automatic adjustment of indoor humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

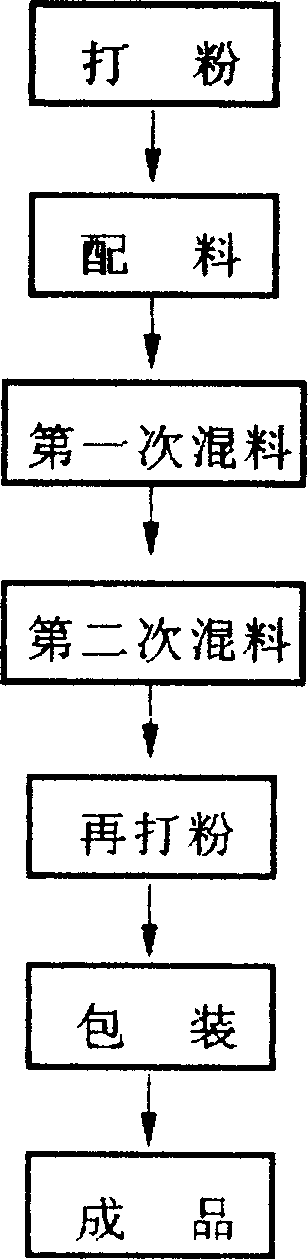

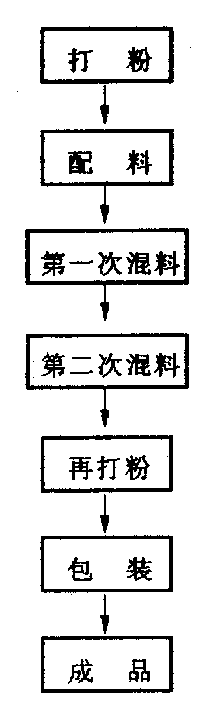

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: get 49.01% unslaked lime, 30.39% water, 0.07% ultramarine blue, 0.28% soda ash, 0.28% borax, 4.83% magnesium sulfate, 1.93% paper tendon, 2.76% plaster powder, 4.83% bleaching powder, 0.22% soda sulfide and 5.4% magnesium oxide (percentage by weight), is processed and produced by the above-mentioned process.

example example 2

[0017] Example 2: Get 55.25% quicklime, 24.51% water, 0.04% ultramarine blue, 0.12% soda ash, 0.12% borax, 4.27% magnesium sulfate, 1.57% paper tendons, 1.47% plaster powder, 4.26% bleaching powder, 8.29% magnesium oxide and 0.1% soda sulfide (percentage by weight), is processed and produced by the above-mentioned process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com