Chitosan/attapulgite composite material and preparation method thereof

A technology of attapulgite and composite materials, applied in chemical instruments and methods, lubricating compositions, other chemical processes, etc., can solve the problem of single types, etc., and achieve the effects of easy separation, difficult secondary pollution, and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S1. be that 0.5kg weight average molecular weight is 600,000, the chitosan powder that degree of deacetylation is greater than 85% is dissolved in the glacial acetic acid aqueous solution of 1% in 25L volume fraction, obtains the chitosan solution that concentration is 20g / L; Disperse 0.3kg of attapulgite modified by acidification in appropriate pure water to obtain attapulgite suspension;

[0039] S2. then add the glycerol of 0.125kg in the chitosan solution, stir in the stirrer and obtain the first solution;

[0040] S3. Slowly add the attapulgite suspension to the first solution under stirring, and after stirring evenly, obtain the second mixed solution;

[0041] S4. Pour the second mixed solution into the mold and freeze at -2-5°C for 5-6 hours, and finally freeze-dry at minus 70-80°C for about 48 hours to obtain the chitosan / attapulgite composite material.

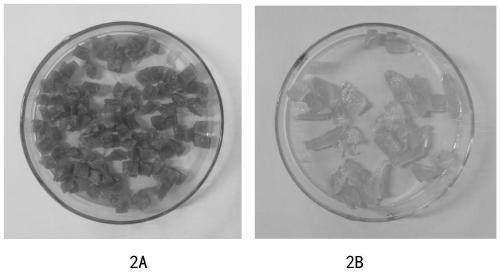

[0042] This embodiment also provides a decolorization system for degraded transformer oil circulation, such...

Embodiment 2

[0045] S1. 0.5kg weight-average molecular weight is 1,000,000, the chitosan powder that degree of deacetylation is greater than 85% is dissolved in 25L volume fraction and is the glacial acetic acid aqueous solution of 1%, obtains the chitosan solution that concentration is 20g / L; Disperse 0.3kg of attapulgite modified by acidification in appropriate pure water to obtain attapulgite suspension;

[0046] S2. then add the glycerol of 0.125kg in the chitosan solution, stir in the stirrer and obtain the first solution;

[0047] S3. Slowly add the attapulgite suspension to the first solution under stirring, and after stirring evenly, obtain the second mixed solution;

[0048] S4. Pour the second mixture into the mold and freeze at -2-5°C for 5-6 hours, and finally freeze-dry at minus 70-80°C for about 48 hours to obtain the chitosan / attapulgite composite material.

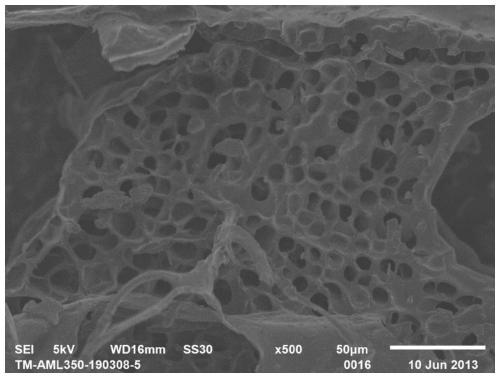

[0049] The chitosan / attapulgite composite material prepared by the present embodiment is scanned under a scanning el...

Embodiment 3

[0053] S1. 0.5kg weight-average molecular weight is 1,000,000, the chitosan powder that degree of deacetylation is greater than 85% is dissolved in 25L volume fraction and is the glacial acetic acid aqueous solution of 1%, obtains the chitosan solution that concentration is 20g / L; Disperse 0.3kg of attapulgite modified by acidification in appropriate pure water to obtain attapulgite suspension;

[0054] S2. then add the glycerol of 0.125kg in the chitosan solution, stir in the stirrer and obtain the first solution;

[0055] S3. Slowly add the attapulgite suspension to the first solution under stirring, and after stirring evenly, obtain the second mixed solution;

[0056] S4. Pour the second mixture into the mold and freeze at -2-5°C for 5-6 hours, and finally freeze-dry at minus 70-80°C for about 48 hours to obtain the chitosan / attapulgite composite material.

[0057] This embodiment also provides a circulating decolorization system for degraded transformer oil. The differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com