Low-compressive creep and high temperature-resistant ethylene propylene rubber material and preparation method thereof

A technology of ethylene-propylene rubber and high temperature resistance, which is applied in the field of rubber, and can solve problems such as the composition of ethylene-propylene rubber materials and mixing methods that cannot be satisfied, and achieve the effects of improving actual use efficiency, preventing agglomeration, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

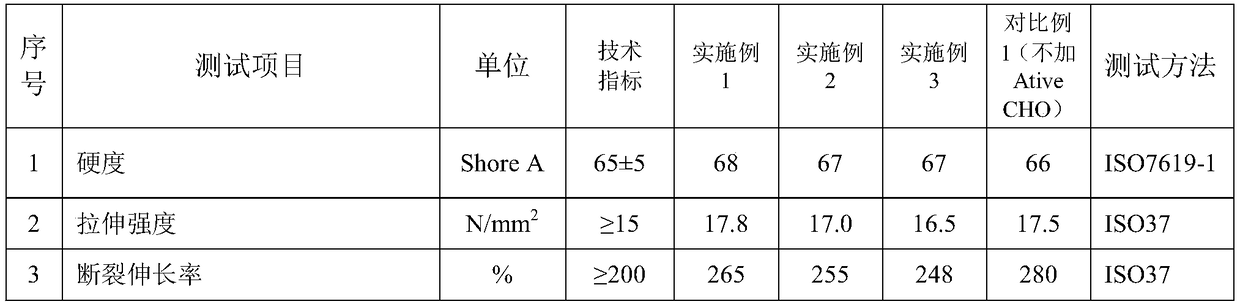

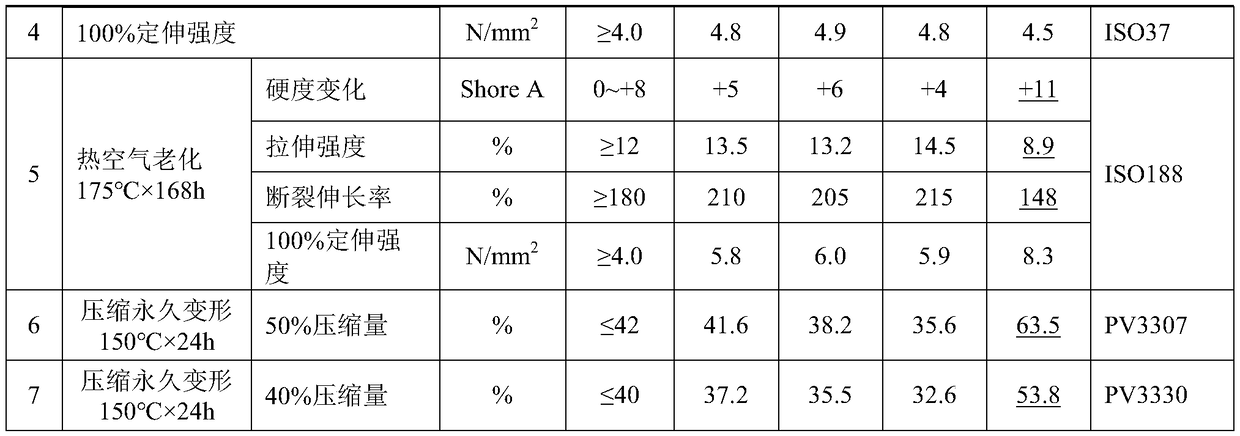

Embodiment 1

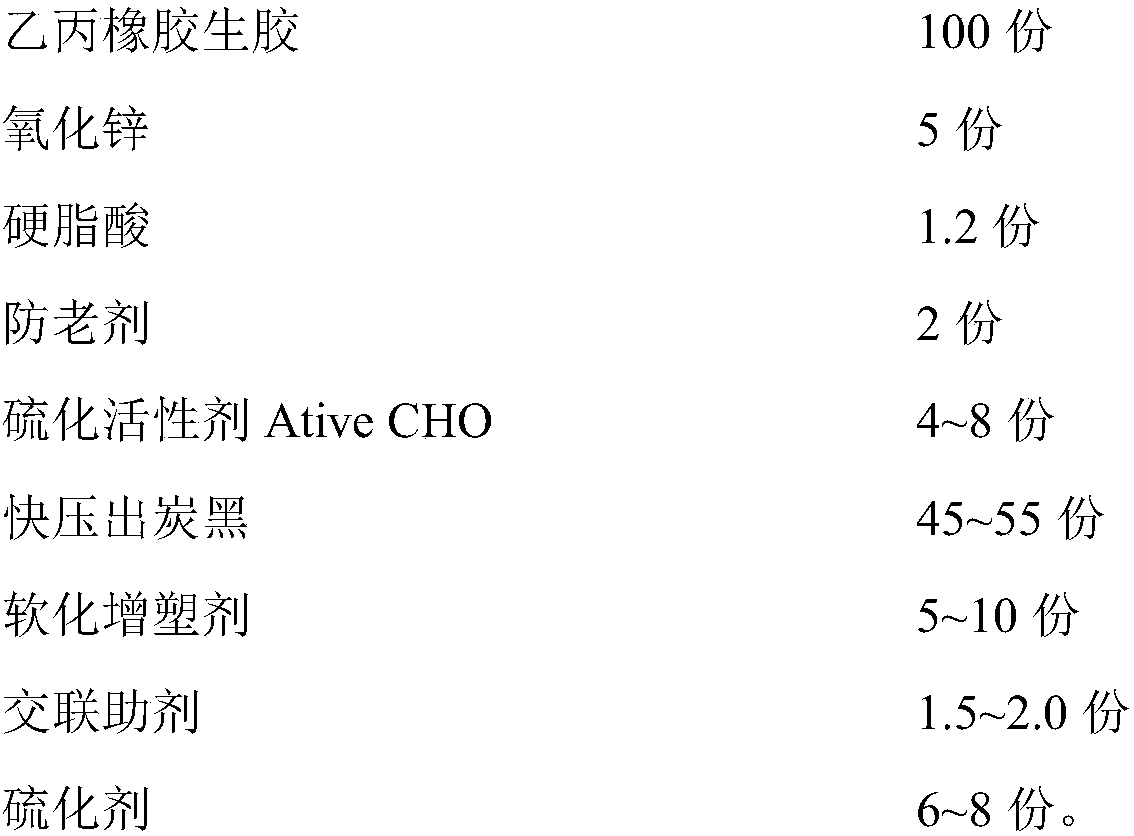

[0046] A low-pressure variable high-temperature resistant ethylene-propylene rubber material of this embodiment includes the following components:

[0047] 100 parts of ethylene-propylene rubber raw rubber, 5 parts of zinc oxide, 1.2 parts of stearic acid, 2 parts of anti-aging agent 445, 6 parts of Active CHO, 55 parts of quick extruded carbon black N550, 10 parts of softening plasticizer S2550, cross-linking aid Agent N308E 1.5 parts and curing agent GF-45 6.0 parts.

[0048] According to the above mass ratio, the preparation method of the low-pressure variable high-temperature resistant ethylene-propylene rubber material is as follows:

[0049] Step 1, preparation of masterbatch rubber: prepare materials according to the formula of low-pressure variable high-temperature resistant ethylene-propylene rubber materials, and put all raw materials except cross-linking aid N308E, vulcanizing agent GF-45 and 1 / 2 amount of Active CHO into the compact In the mixing machine, the temp...

Embodiment 2

[0053] A low-pressure variable high-temperature resistant ethylene-propylene rubber material of this embodiment includes the following components:

[0054] 100 parts of ethylene propylene rubber raw rubber, 5 parts of zinc oxide, 1.2 parts of stearic acid, 2 parts of anti-aging agent 445, 8 parts of Active CHO, 50 parts of quick extruded carbon black N550, 7 parts of softening plasticizer S2550, crosslinking aid Agent N308E 1.8 parts and curing agent GF-45 7.2 parts.

[0055] According to the above mass ratio, the preparation method of the low-pressure variable high-temperature resistant ethylene-propylene rubber material is as follows:

[0056] Step 1, preparation of masterbatch rubber: prepare materials according to the formula of low-pressure variable high-temperature resistant ethylene-propylene rubber materials, and put all raw materials except cross-linking aid N308E, vulcanizing agent GF-45 and 1 / 2 amount of Active CHO into the compact In the mixing machine, the temper...

Embodiment 3

[0060] A low-pressure variable high-temperature resistant ethylene-propylene rubber material of this embodiment includes the following components:

[0061] 100 parts of ethylene propylene rubber raw rubber, 5 parts of zinc oxide, 1.2 parts of stearic acid, 2 parts of anti-aging agent 445, 4 parts of Active CHO, 45 parts of quick extruded carbon black N550, 5 parts of softening plasticizer S2550, cross-linking aid Agent N308E 2.0 parts and curing agent GF-45 8.0 parts.

[0062] According to the above mass ratio, the preparation method of the low-pressure variable high-temperature resistant ethylene-propylene rubber material is as follows:

[0063] Step 1, preparation of masterbatch rubber: prepare materials according to the formula of low-pressure variable high-temperature resistant ethylene-propylene rubber materials, and put all raw materials except cross-linking aid N308E, vulcanizing agent GF-45 and 1 / 2 amount of Active CHO into the compact In the mixing machine, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com