Primer matched paint and preparation method thereof

A primer and coating technology, which is applied in the direction of anti-corrosion coatings, magnetic coatings, chemical instruments and methods, etc., can solve the problems of machine position occupation, long coating process cycle, high energy consumption, etc., and achieve improved salt spray resistance and reduced VOC emission, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A primer supporting coating, which is composed of light-curing fluorine-containing aircraft skin enamel and ultraviolet light-curing acrylic polyurethane primer, wherein,

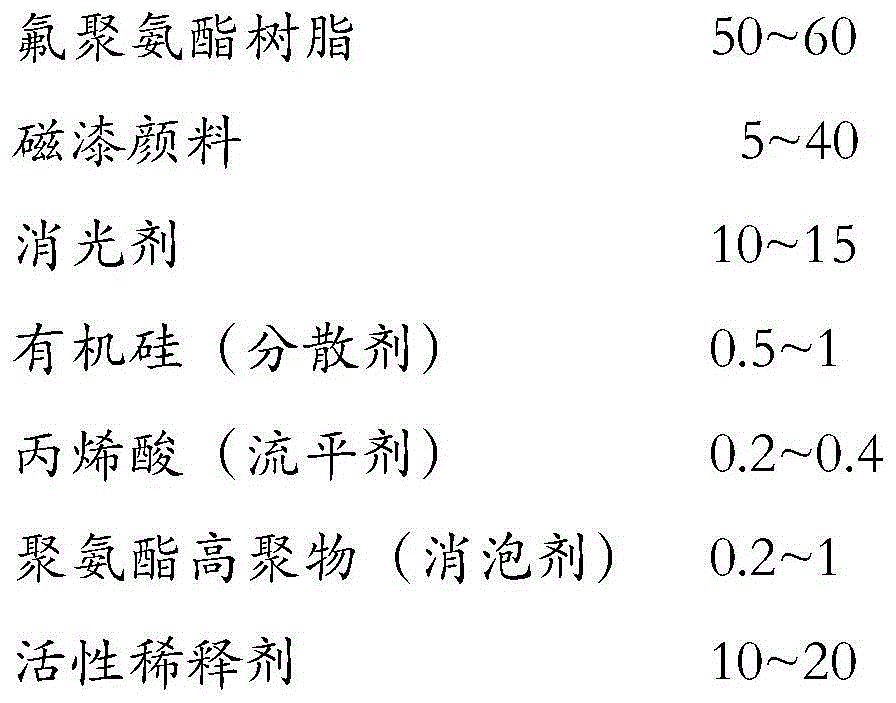

[0027] The light-curing fluorine-containing aircraft skin enamel is composed of the following components, in parts by weight (parts):

[0028]

[0029]

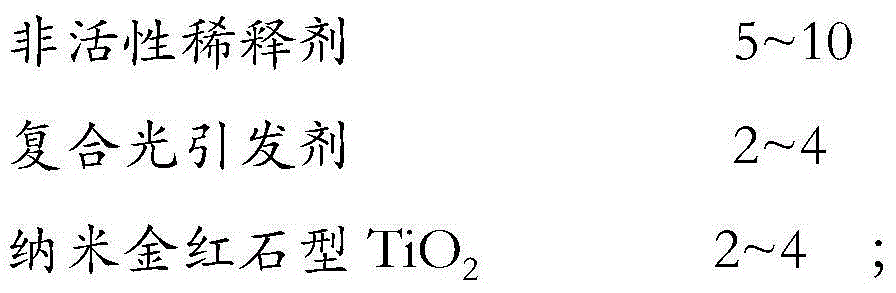

[0030] Described ultraviolet curing acrylic polyurethane primer is made up of following components, by its weight parts (parts),

[0031]

[0032] The enamel pigment is phthalocyanine blue (blue); the reactive diluent consists of 3 parts by weight of butyl methacrylate, 5 parts of ethylene glycol dimethacrylate, trimethylolpropane triacrylic acid 2 parts of esters are mixed; the non-reactive diluent is formed by mixing 4 parts of butyl acetate and 4 parts of xylene in parts by weight; the composite photoinitiator is composed of isopropylthia Anthrone (ITX) 1.8 parts, 2-methyl-1-(4-methylmercaptophenyl)-2-morpholine-1-propanone (907) 1.7 pa...

Embodiment 2

[0035] A primer supporting coating, which is composed of light-curing fluorine-containing aircraft skin enamel and ultraviolet light-curing acrylic polyurethane primer, wherein,

[0036] The photocurable fluorine-containing aircraft skin enamel is composed of the following components, in parts by weight:

[0037]

[0038]

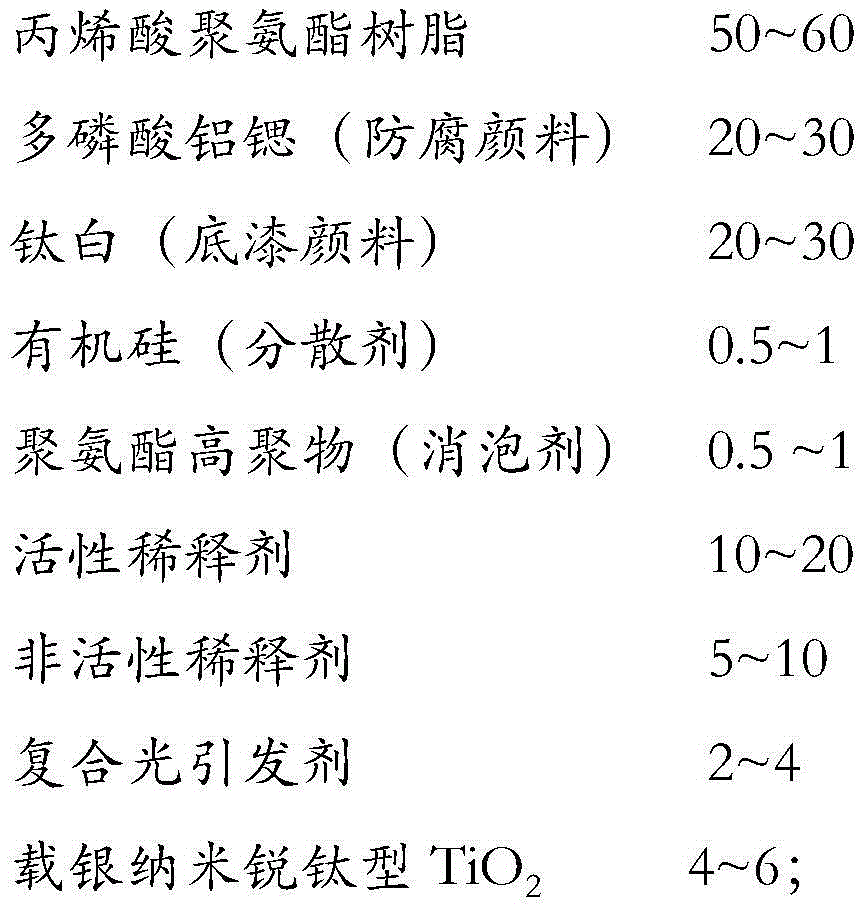

[0039] The UV-curable acrylic polyurethane primer consists of the following components, in parts by weight,

[0040]

[0041] The enamel pigment is a complex color obtained by compounding titanium dioxide (white) and organic pigment red (red) in a weight ratio of 2:1; the reactive diluent consists of 4 parts by weight of butyl methacrylate , 4 parts of ethylene glycol dimethacrylate, and 1 part of trimethylolpropane triacrylate; the inactive diluent is prepared by mixing 3 parts of butyl acetate and 5 parts of xylene in parts by weight. into; the composite photoinitiator consists of 2 parts by weight of isopropylthioxanthone (ITX), 2-methyl-1-(4-m...

Embodiment 3

[0044] A primer supporting coating, which is composed of light-curing fluorine-containing aircraft skin enamel and ultraviolet light-curing acrylic polyurethane primer, wherein,

[0045] The photocurable fluorine-containing aircraft skin enamel is composed of the following components, in parts by weight:

[0046]

[0047] The UV-curable acrylic polyurethane primer consists of the following components, in parts by weight,

[0048]

[0049] The enamel pigment is carbon black (black); the reactive diluent consists of 2 parts by weight of butyl methacrylate, 6 parts of ethylene glycol dimethacrylate, 3 parts of trimethylolpropane triacrylate parts by weight; the non-reactive diluent is mixed by 5 parts by weight of butyl acetate and 3 parts by xylene; (ITX) 1.5 parts, 2-methyl-1-(4-methylmercaptophenyl)-2-morpholine-1-propanone (907) 2 parts, 4-dimethylaminobenzoic acid ethyl ester (EDAB) 2 parts , 2 parts of benzophenone (BP) and 1 part of active tertiary amine (P115); 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com