Single-component water-soluble insulated enamel paint and preparation method thereof

A technology of water-soluble and water-soluble acrylic acid, which is applied in the direction of coating, etc., can solve problems such as poor stability, inability to apply in the field of electrical insulation treatment, and decline in water resistance of paint films, and achieve strong adhesion, good decorative and beautifying effects, and curing speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

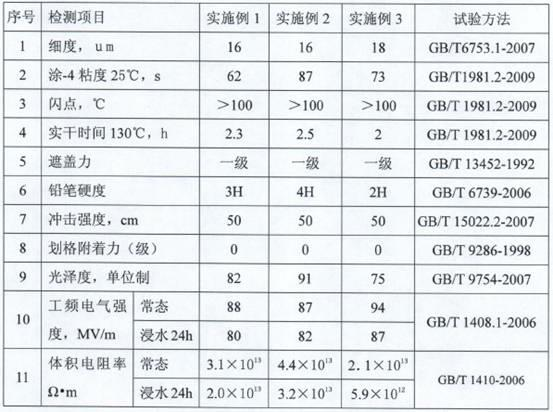

Examples

Embodiment 1

[0029] A one-component water-soluble insulating varnish, comprising 26 parts by weight of water-soluble acrylic resin, 6.5 parts by weight of amino resin curing agent, 36 parts by weight of water, 1.7 parts by weight of neutralizing agent, 2.5 parts by weight of cosolvent, and 31 parts by weight of pigments and fillers , 0.1 part by weight of wetting agent, 0.1 part by weight of dispersant, 0.1 part by weight of defoamer and 0.1 part by weight of leveling agent.

[0030] The water-soluble acrylic resin is HD-AP1041 produced by Beijing Jinhuili Applied Chemical Products Co., Ltd. The amino resin curing agent is HL-5747 full methyl etherified amino resin produced by Taizhou Xinhua Resin Co., Ltd. The water is industrial deionized water, the range of conductivity is 10-0.1us / cm, and the range of resistivity is 1-15MΩ·m. Described neutralizing agent is triethylamine. Described auxiliary solvent is ethanol. The pigment and filler is titanium dioxide. The wetting agent is Disper...

Embodiment 2

[0035] A one-component water-soluble insulating varnish, comprising 33 parts by weight of water-soluble acrylic resin, 11 parts by weight of amino resin curing agent, 28 parts by weight of water, 2.4 parts by weight of neutralizing agent, 5 parts by weight of cosolvent, and 37 parts by weight of pigments and fillers , 0.3 parts by weight of wetting agent, 0.3 parts by weight of dispersant, 0.3 parts by weight of defoamer and 0.3 parts by weight of leveling agent.

[0036] The water-soluble acrylic resin is HD-AP1041 produced by Beijing Jinhuili Applied Chemical Products Co., Ltd., its acid value is 40 mgKOH / g, and its hydroxyl value is 30 mgKOH / g. The amino resin curing agent is SM5717 partially methylated amino resin produced by Jiangsu Sanmu Group Co., Ltd. The water is industrial deionized water, the range of conductivity is 10-0.1us / cm, and the range of resistivity is 1-15MΩ·m. Described neutralizing agent is ethylenediamine. Described auxiliary solvent is butanol. The pi...

Embodiment 3

[0041] A one-component water-soluble insulating varnish, comprising 30 parts by weight of water-soluble acrylic resin, 8 parts by weight of amino resin curing agent, 30 parts by weight of water, 2 parts by weight of neutralizing agent, 4 parts by weight of cosolvent, and 35 parts by weight of pigment and filler , 0.2 parts by weight of wetting agent, 0.2 parts by weight of dispersant, 0.1 part by weight of defoamer and 0.1 part by weight of leveling agent.

[0042] The water-soluble acrylic resin is EA3842 produced by Jiangsu Sanmu Group Co., Ltd. The amino resin curing agent is HL-5747 produced by Taizhou Xinhua Resin Co., Ltd. The water is industrial deionized water, the range of conductivity is 10-0.1us / cm, and the range of resistivity is 1-15MΩ·m. Described neutralizing agent is dimethylethanolamine. The co-solvent is 2 parts by weight of ethylene glycol butyl ether and 2 parts by weight of propylene glycol methyl ether. The pigment and filler is lithopone. Described w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com