Alkyd resin for quickly drying alkyd enamel paint and preparation method thereof

A technology of alkyd enamel and alkyd resin, applied in the field of resin, can solve the problems of high cost and achieve the effects of improved product quality, fast drying at room temperature, and increased crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of preparation method of quick-drying alkyd enamel alkyd resin of the present invention comprises the following steps:

[0022] A. Primary esterification: Put 50-55 parts of soybean oil fatty acid, 19.3-20.4 parts of glycerin, 27.1-31.8 parts of terephthalic acid, and 0.03-0.09 parts of hypophosphorous acid into the reactor, close the feeding port, and heat up to 245- 255°C, turn on the cooling water of the reflux condenser, keep warm and reflux for 4-6 hours until the resin liquid is transparent, and the acid value detected by the sampling center control is below 2mgKOH / g; the product is the A-stage resin, and the temperature of the A-stage resin is raised to 245-255 °C, the purpose is that it evaporates together with the water produced in the esterification reaction, cools through the condenser, and then sinks the water through the water separator. The resin in stage A flows back into the kettle, and the reaction is completed in the specified direction. The aci...

Embodiment

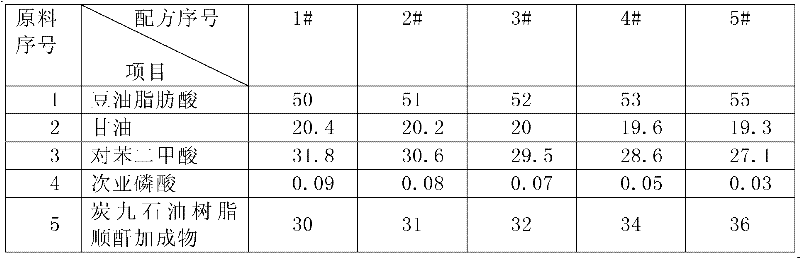

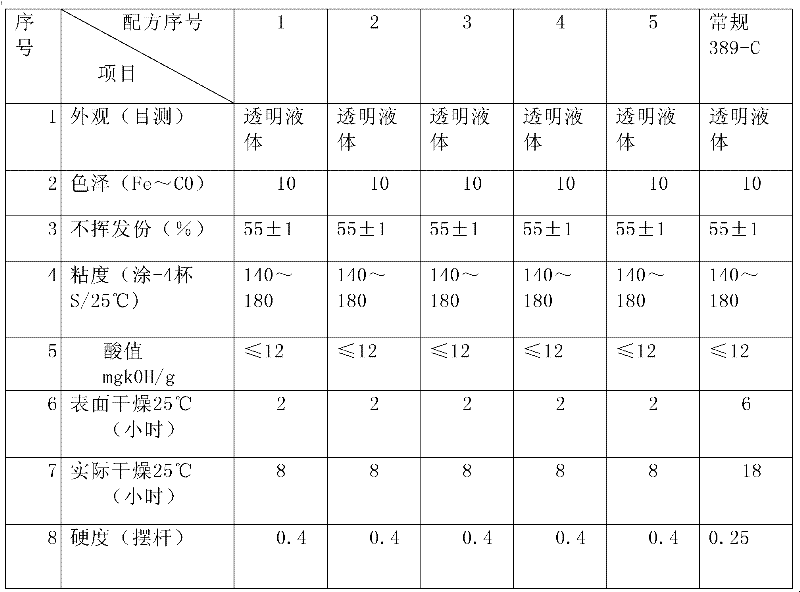

[0030] Put the raw materials listed in the following table 1 according to the ratio of parts by weight into the reaction kettle, close the feeding port, start stirring when the temperature rises, and turn on the cooling water of the reflux condenser when the temperature rises to 245-255°C, and keep the temperature and reflux for 4-6 hours to The resin liquid is transparent, and the acid value detected by the sampling center control is below 2mgKOH / g. After the material is transparent, the temperature is lowered to 180 ° C ~ 200 ° C, and the feeding port is opened. At the same time, the vacuum is turned on, and the volatilized xylene gas is sucked into the recovery tank. , put in 30-36 parts of petroleum resin maleic anhydride adducts, turn off the vacuum, add 2 parts of xylene, adjust the temperature to 210°C-220°C, and keep warm and esterify until the acid value measured by the central control is 20mgKOH / g in the reflux state Hereinafter, the gravitational tube viscosity is 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com