Waterborne polyurethane enamel paint and preparation method and application method thereof

A technology of polyurethane and polyurethane emulsion, applied in polyurea/polyurethane coatings, magnetic coatings, coatings, etc., can solve the problems of large color difference in batches of natural colored sand, excessive use of natural colored sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

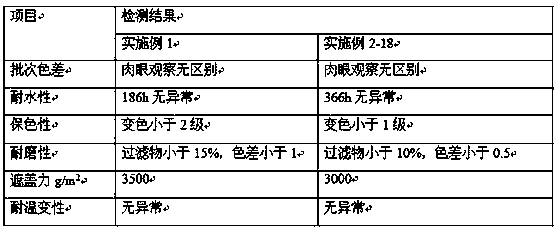

Examples

Embodiment 1

[0081] The preparation method of the artificial colored sand of the present embodiment, comprises the steps:

[0082] (1) Mixing: Add 50 parts of water and 0.1 part of hydroxypropyl methylcellulose into the mixer and stir for 5 minutes at a speed of 500 r / min. After the hydroxypropyl methylcellulose is fully dissolved, add 0.5 parts of wetting agent, 0.2 parts by weight of antifoaming agent, 2 parts of dispersant and stir evenly;

[0083] (2) Dispersion: add 20 parts of titanium dioxide to the mixer at a speed of 600r / min, and stir at 1600r / min for 20 minutes;

[0084] (3) Paint mixing: Add 210 parts of polyurethane emulsion, 5 parts of film-forming aid, and 0.35 parts by weight of defoamer to the mixer at a speed of 600r / min, stir for 10 minutes, and then add 2-6 parts of coupling agent , stirring and mixing, the obtained viscosity is the polyurethane water-based enamels of 70KU;

[0085] (4) Toning: add water-based color paste to the polyurethane water-based enamel describ...

Embodiment 2

[0089] The preparation method of the artificial colored sand of the present embodiment, comprises the steps:

[0090] (1) Mixing: Add 64 parts of water, 0.3 parts of hydroxypropyl methylcellulose, and 1.5 parts of rheological agent (polyurethane) into the mixer and stir at a speed of 500r / min for 5 minutes, then add 0.4 parts of AMP-95, and wait until the hydroxyl After the propyl methylcellulose is fully dissolved, add 0.3 parts of nonionic wetting agent, 0.5 parts by weight of defoamer, and 2.0 parts of ammonium salt dispersant and stir evenly;

[0091] (2) Dispersion: Add 35 parts of titanium dioxide and 160 parts of heavy calcium carbonate to the mixer at a speed of 600r / min and stir for 20 minutes at a mixer speed of 1500r / min;

[0092] (3) Paint adjustment: add 218 parts of polyurethane emulsion, 7.7 parts of alcohol ester twelve, 0.9 parts of defoamer at the speed of 600r / min in the mixer, stir for 10 minutes, and then add 1.0 parts of polyurethane leveling agent (alkyl...

Embodiment 3

[0096] The preparation method of the artificial colored sand of the present embodiment, comprises the steps:

[0097] (1) Mixing: Add 150 parts of water, 0.5 parts of hydroxypropyl methylcellulose, and 3.0 parts of rheological agent (polyacrylate) into the mixer and stir at a speed of 600r / min for 6 minutes, then add 0.6 parts of AMP-95, After the hydroxypropyl methylcellulose is fully dissolved, add 0.5 parts of a wetting agent, 1.0 parts by weight of an antifoaming agent, and 6 parts of a dispersant and stir evenly;

[0098] (2) Dispersion: Add 50 parts of titanium dioxide and 180 parts of heavy calcium carbonate to the mixer at a speed of 700r / min, and stir at 1800r / min for 25 minutes;

[0099] (3) Paint mixing: Add 230 parts of polyurethane emulsion, 10 parts of film-forming aids, 2.0 parts by weight of defoamer to the mixer at a speed of 700r / min, stir for 15 minutes, and then add 2.0 parts of leveling agent (alkane base modified organosiloxane), 6 parts of coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com