Method for producing enamel covered aluminum flat wire

A production method and enameled aluminum technology, which are used in cable/conductor manufacturing, flat/ribbon cables, base materials, etc., can solve the problems of inability to meet the needs of national defense and civil electrical equipment, large gaps in enameled wires, and large coil volume. , to achieve the effect of good practicability and promotion value, high tank full rate and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

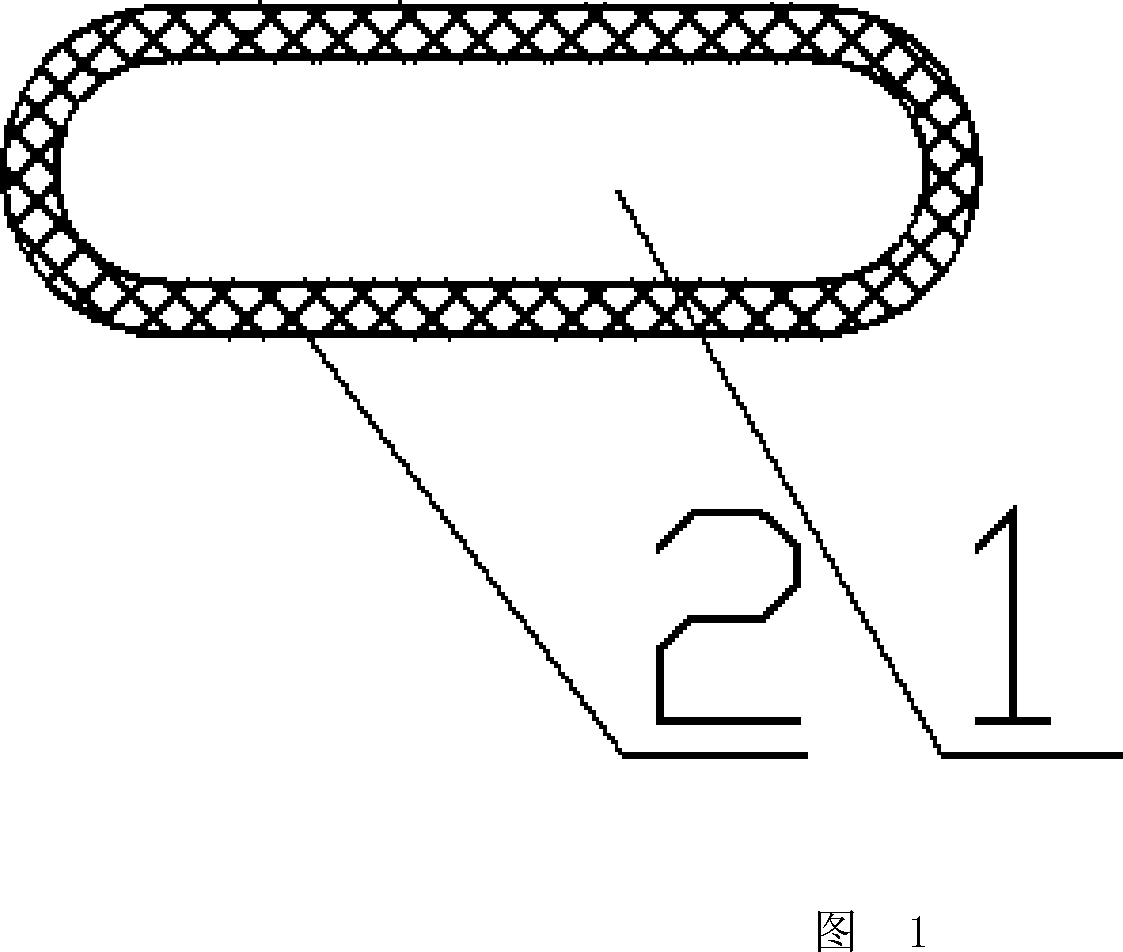

[0012] Embodiment of the present invention: the aluminum wire is made into a thin and flat aluminum wire by extrusion and stretching, and the cost of the aluminum wire can be saved by nearly 60% compared with the copper wire, and the stretching lubricating fluid is used when stretching, The drawing lubricating fluid is a special wire drawing lubricating liquid for aluminum wires. The special wire drawing lubricating liquid for aluminum wires is composed of 78-92 parts by mass of rapeseed oil, 3-7 parts of kerosene, 9-10 parts of diesel oil, and 0.1-1 part of phenol. . Clean the thin and flat aluminum wire 1 after stretching with an alkaline cleaning solution to remove oil stains on the surface of the thin and flat aluminum wire. The pH value of the alkaline cleaning solution used is between 8 and 9, and then pass The organic solution removes the oxide layer on the surface of the thin and flat aluminum wire 1. The organic solution used is a cleaning agent for bare aluminum wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com