Carbon fiber material framework

A carbon fiber material and frame technology, which is applied to bogies, devices that move laterally between the underframe and bogies, and railway car body parts, can solve the problems of small gaps in the internal structure of the frame, vibration reduction, damping, and deformation. Poor capacity, complex welding bogie structure and other problems, to achieve the effect of low molding process cost, good elastic deformation performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

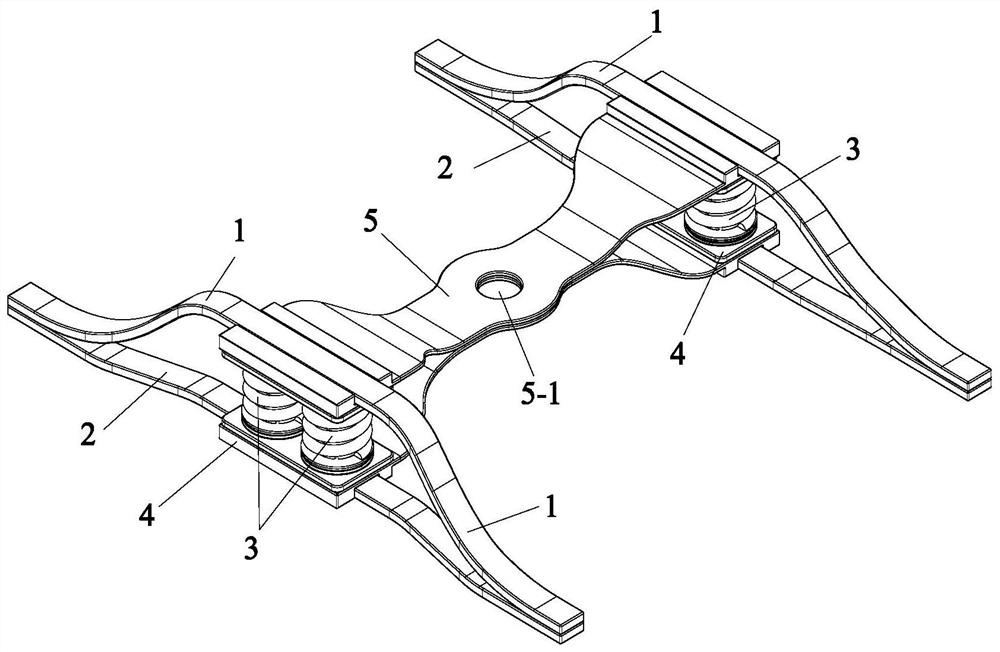

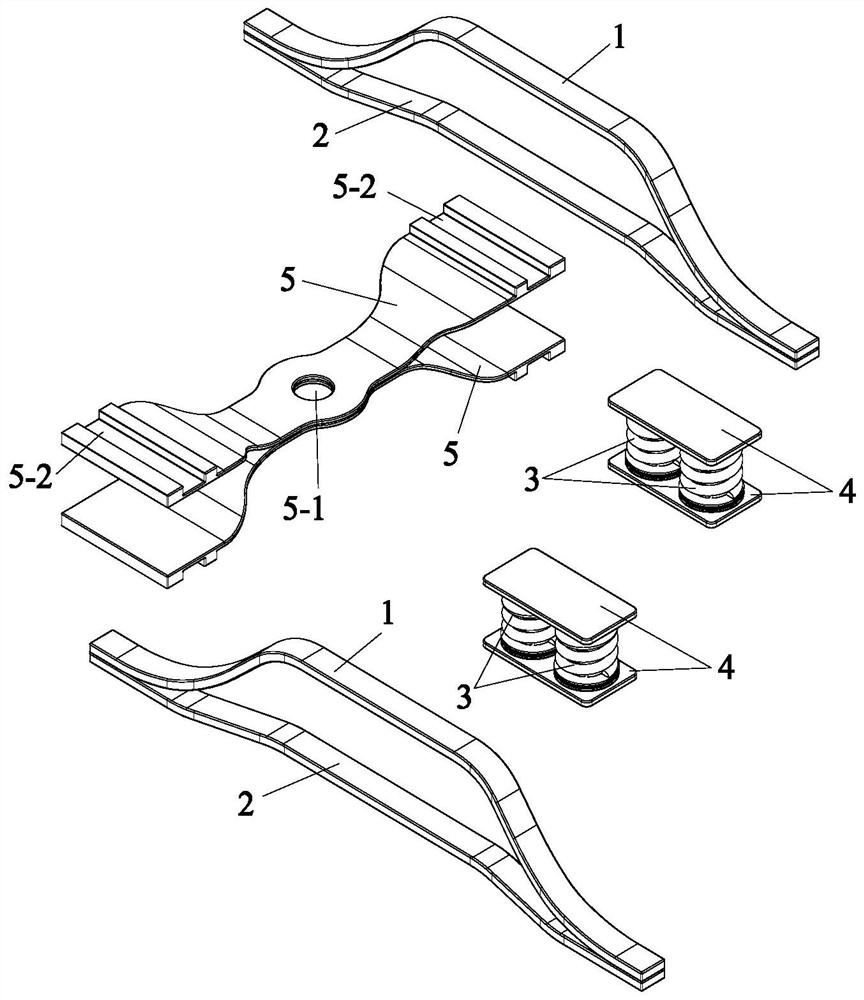

[0027] Such as Figure 1 to Figure 9 As shown, the carbon fiber material frame of the present invention comprises two bow-shaped side beams, an X-shaped load-bearing beam and two side beam double spring group support seats;

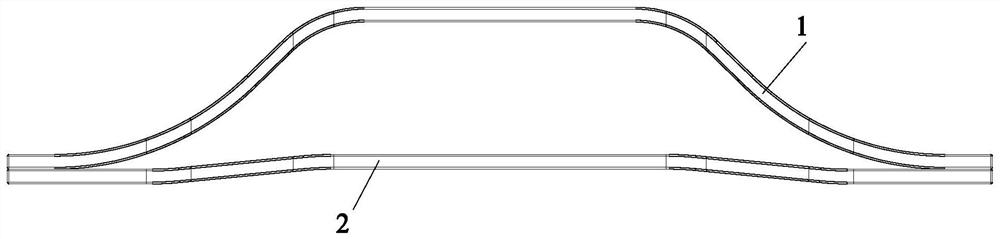

[0028] The bow-shaped side beam consists of a bow-shaped upper beam 1 and a bow-shaped lower beam 2, and the two ends of the two are fixedly connected to each other according to the structure of the bow and arrow and the bow arm;

[0029] The X-shaped load-bearing crossbeam includes two arched plate beams 5, the middle part of the horizontal section of the middle part of the arched plate beam 5 is provided with a central through hole 5-1 of the plate beam, and the two ends of the arched plate beam 5 are symmetrically arranged with transverse The opened side beam positioning slot 5-2 and its slotting direction are perpendicular to the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com