A glass fiber reinforced cement composite thermal insulation wallboard and its manufacturing method

A technology of glass fiber and reinforced cement, which is applied in the processing of building components, building materials, construction, etc. It can solve the problems of short service life of the insulation layer, long construction period, poor fire performance, etc., and achieve cost reduction, construction process reduction, The effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

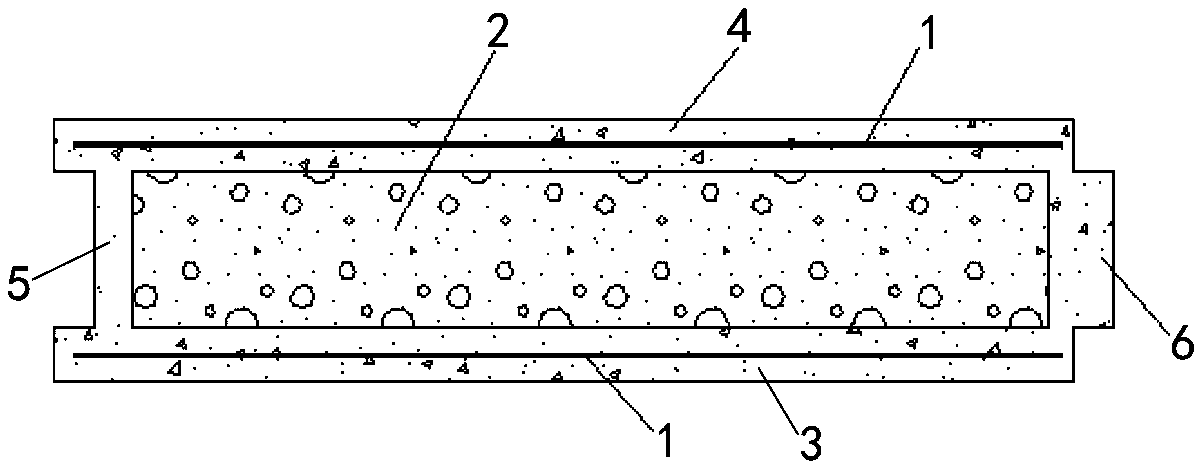

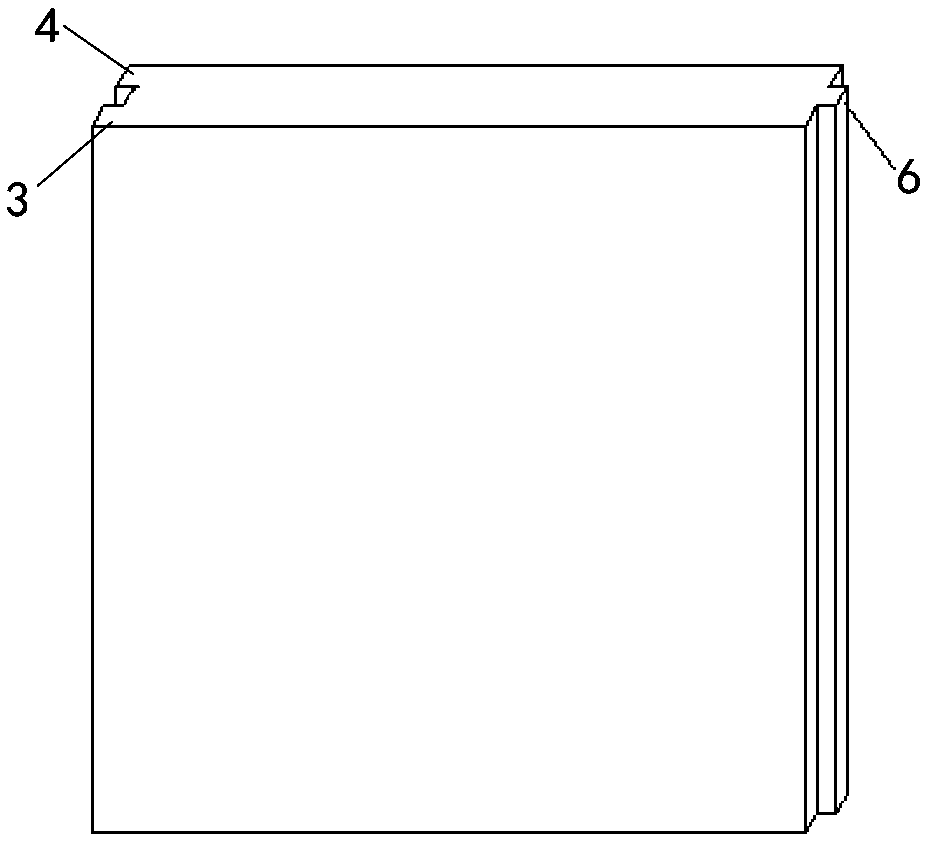

[0053] see Figure 1-2 As shown, a glass fiber reinforced cement composite thermal insulation wallboard includes a thermal insulation core board 2 and an outer frame enclosed around the sides of the thermal insulation core board, and the outer frame includes a front side panel 3 made of glass fiber reinforced cement, The rear side plate 4 , the left end plate 5 and the right end plate 6 , the insides of the front side plate 3 and the rear side plate 4 are all embedded with galvanized steel wire mesh 1 . The front side board 3 and the rear side board 4 are aligned front and rear. For reliable and convenient connection, the left end surface of the left end plate 5 is concave relative to the left end surfaces of the two side plates, and the right end surface of the right end plate 6 protrudes relative to the right end surfaces of the two side plates.

[0054]In this embodiment, the thickness of the wallboard can be 200mm, the width can be designed in two specifications of 780mm ...

Embodiment 2

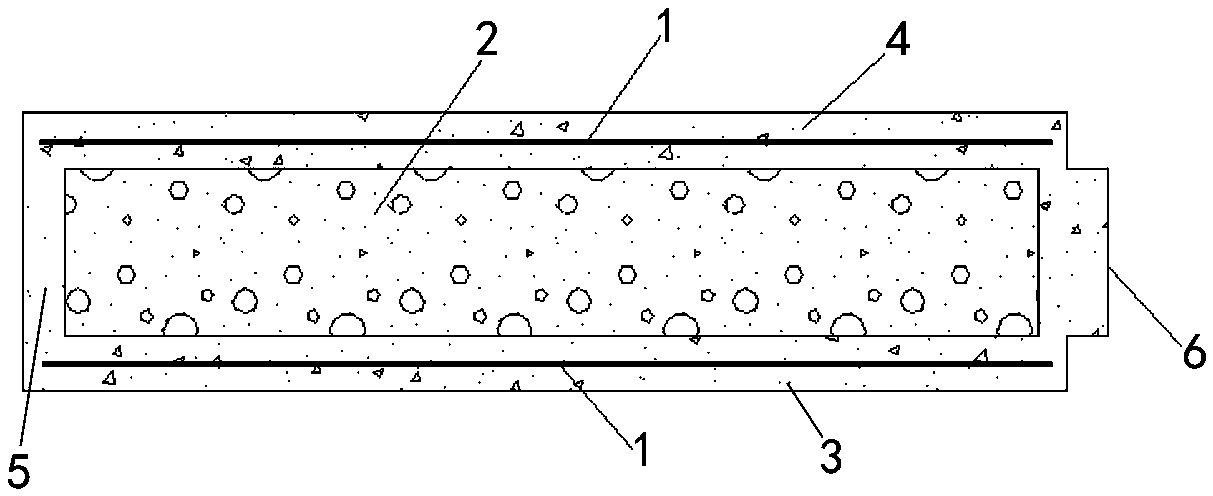

[0077] see Figure 3-4 As shown, the wallboard structure is the same as that of Embodiment 1.

[0078] The outer frame is made of glass fiber reinforced cement, and the insulation core board is made of modified concrete. The raw materials of the modified concrete include ordinary Portland cement, tailings sand, water, and modified corn stalks. , polystyrene foam particles, latex powder and water reducer. The modification treatment of corn stalks mainly refers to: first soak corn stalks with 3.5% sodium hydroxide solution for 8-12 hours to remove organic components in corn stalks; then use 1.0% sodium hydroxide solution The sodium silicate solution is uniformly sprayed on the surface of the above-mentioned corn stalks to perform chemical accelerated plugging to increase the bonding force between the corn stalks and the concrete.

[0079] In the modified concrete, the weight parts of ordinary Portland cement, tailings sand, water, latex powder and water reducing agent are as f...

Embodiment 3

[0099] see Figure 3-4 As shown, the difference from Embodiment 1 is that the left end surface of the left end plate 5 is flush with the left end surfaces of the two side plates, and the right end surface of the right end plate 6 protrudes relative to the right end surfaces of the two side plates.

[0100] The outer frame is made of glass fiber reinforced cement, and the insulation core board is made of modified concrete. The raw materials of the modified concrete include ordinary Portland cement, tailings sand, water, and modified corn stalks. , polystyrene foam particles, latex powder and water reducer. The modification treatment of corn stalks mainly refers to: first soak corn stalks with 3.5% sodium hydroxide solution for 8-12 hours to remove organic components in corn stalks; then use 1.0% sodium hydroxide solution The sodium silicate solution is uniformly sprayed on the surface of the above-mentioned corn stalks to perform chemical accelerated plugging to increase the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com