Bi-component fluorinated polyurethane enamel paint with high emissivity and preparation method thereof

A polyurethane enamel, two-component technology, used in polyurea/polyurethane coatings, magnetic coatings, coatings, etc., can solve problems such as lack of other functions and inability to meet the requirements of new fighter aircraft, and achieve the effect of a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

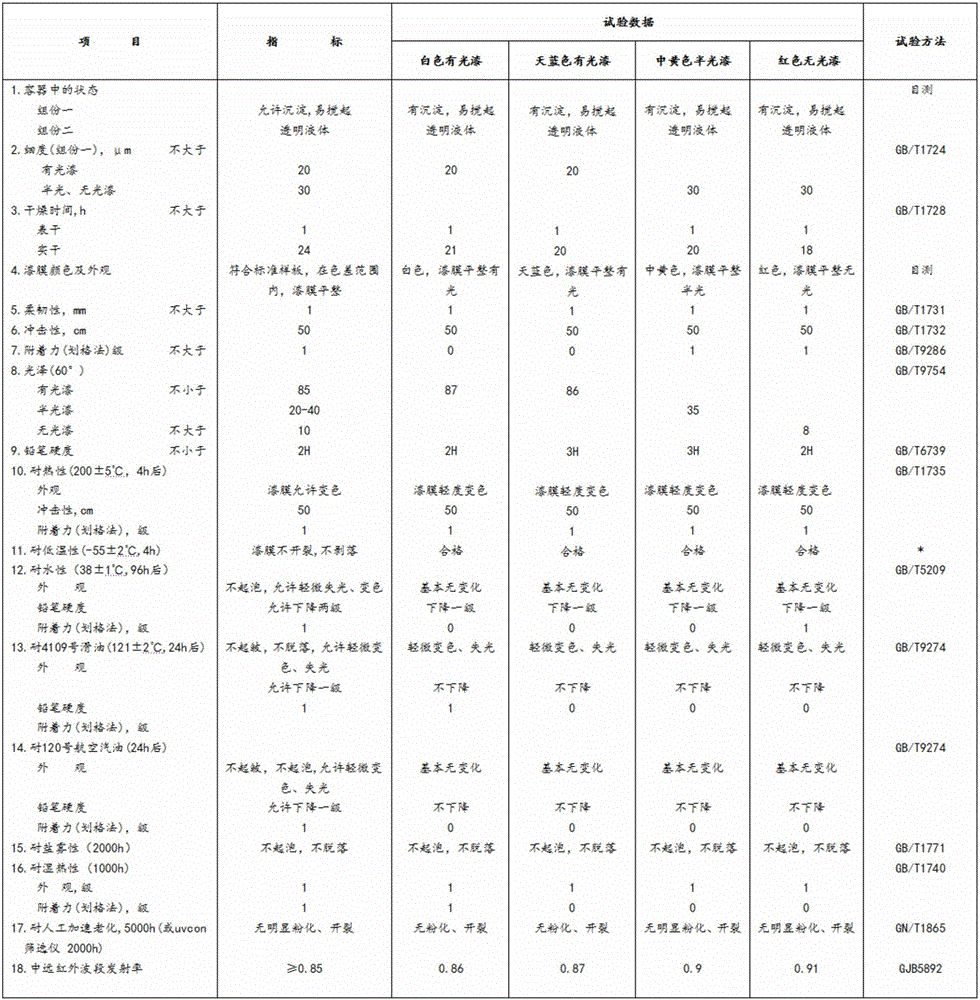

[0035] Embodiment 1 (white glossy enamel paint)

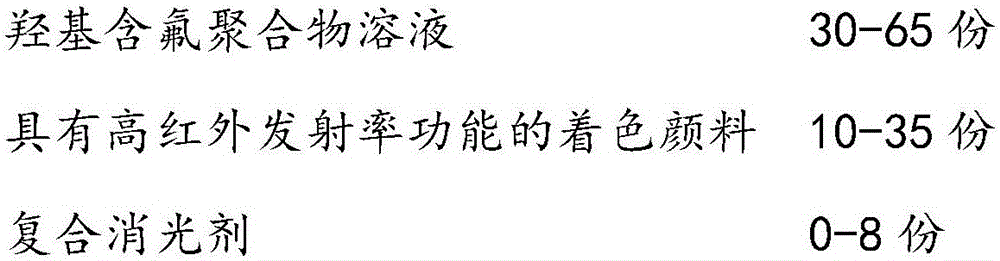

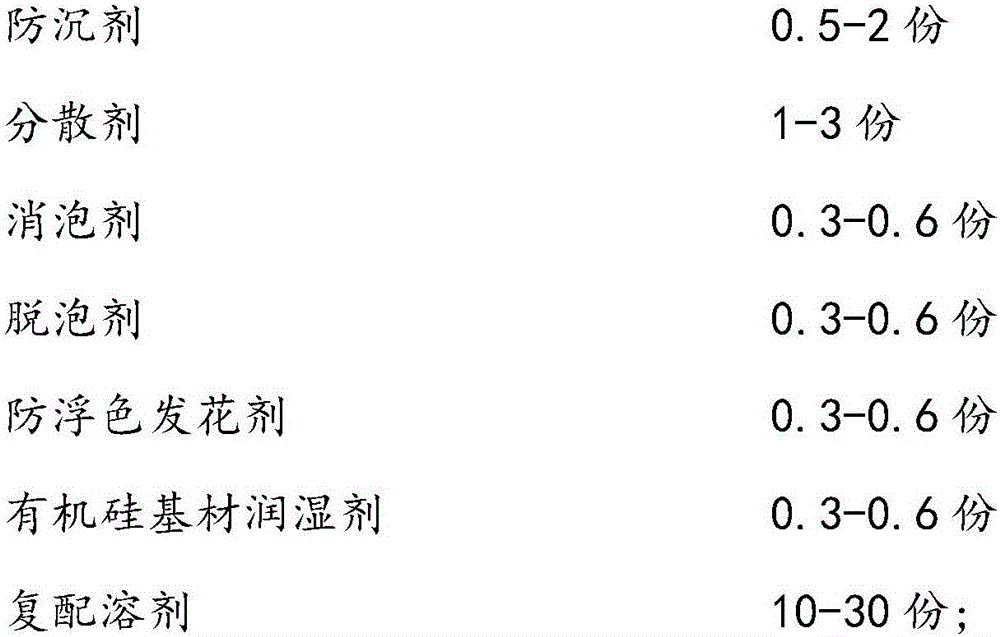

[0036] A two-component fluorine-containing polyurethane enamel with high emissivity function is composed of A and B components, and the A component comprises the following components, by weight g,

[0037] Hydroxyl fluoropolymer solution 50, coloring pigment R titanium dioxide with high infrared emissivity function 30, anti-settling agent 1, wetting and dispersing agent 1, defoaming agent 0.5, defoaming agent 0.3, anti-floating and flowering agent 0.3, base Material wetting agent 0.3, compound solvent 16.6

[0038] B component is weather-resistant aliphatic isocyanate curing agent 35

[0039] The A component and the B component are mixed according to the weight ratio of 100:35 and added with 10-20% compounding solvent, left for about 30 minutes, and then sprayed.

[0040] Ⅰ. The preparation of component A is in parts by weight:

[0041] ① Add 1 / 2 of the formula of hydroxyl fluoropolymer solution, wetting and dispersing agent...

Embodiment 2

[0046] Embodiment 2 (sky blue glossy enamel paint)

[0047] A kind of two-component fluorine-containing polyurethane according to the enamel paint with high emissivity function, is made up of A, B two components, and described A component comprises following component, by weight g,

[0048] Hydroxyl fluoropolymer solution 55, coloring pigment R titanium dioxide with high infrared emissivity function 20, phthalocyanine blue 5, anti-sedimentation agent 1, wetting and dispersing agent 2.5, defoaming agent 0.5, defoaming agent 0.3, anti-floating color hair Flower agent 0.5, substrate wetting agent 0.5, compound solvent 14.7.

[0049] Component B is weather-resistant aliphatic isocyanate curing agent 38.5.

[0050] The A component and the B component are mixed according to the weight ratio of 100:38.5 and added with 10-20% compounding solvent, left for about 30 minutes and then sprayed.

[0051] The preparation method of the above-mentioned two-component fluorine-containing polyu...

Embodiment 3

[0052] Embodiment 3 (medium yellow semi-gloss enamel)

[0053] A kind of two-component fluorine-containing polyurethane according to the enamel paint with high emissivity function, is made up of A, B two components, and described A component comprises following component, by weight g,

[0054] Hydroxyl fluoropolymer solution 40, high infrared emissivity functional coloring pigment R titanium dioxide 10, bismuth vanadate yellow 25, composite matting agent 4, anti-sedimentation agent 1, wetting and dispersing agent 1.1, defoaming agent 0.4, defoaming agent 0.4, anti-floating and hair-blowing agent 0.4, substrate wetting agent 0.3, compound solvent 17.4.

[0055] Component B is weather-resistant aliphatic isocyanate curing agent 28.

[0056] The A component and the B component are mixed according to the weight ratio of 100:28 and added with 10-20% compounding solvent, left for about 30 minutes and then sprayed.

[0057] The preparation method of the above-mentioned two-componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com