Electric heating tube component and manufacturing method thereof

The technology of an electric heating tube and its manufacturing method is applied in the electric heating tube component with enamel protective layer and its manufacturing field, which can solve the problems that cannot meet the production needs, the enamel coating is not covered, and the scale is accumulated at the end. Life extension, long service life, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

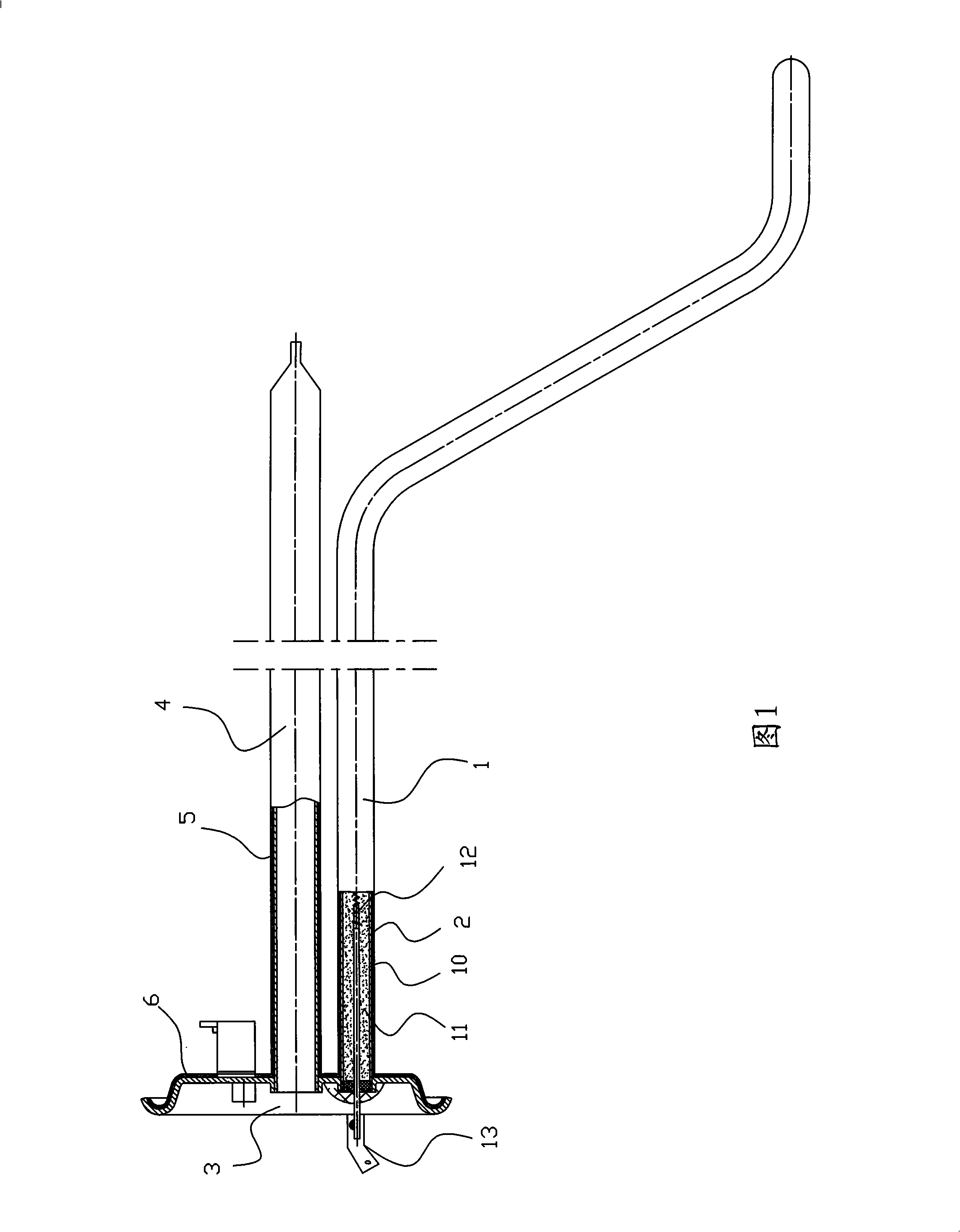

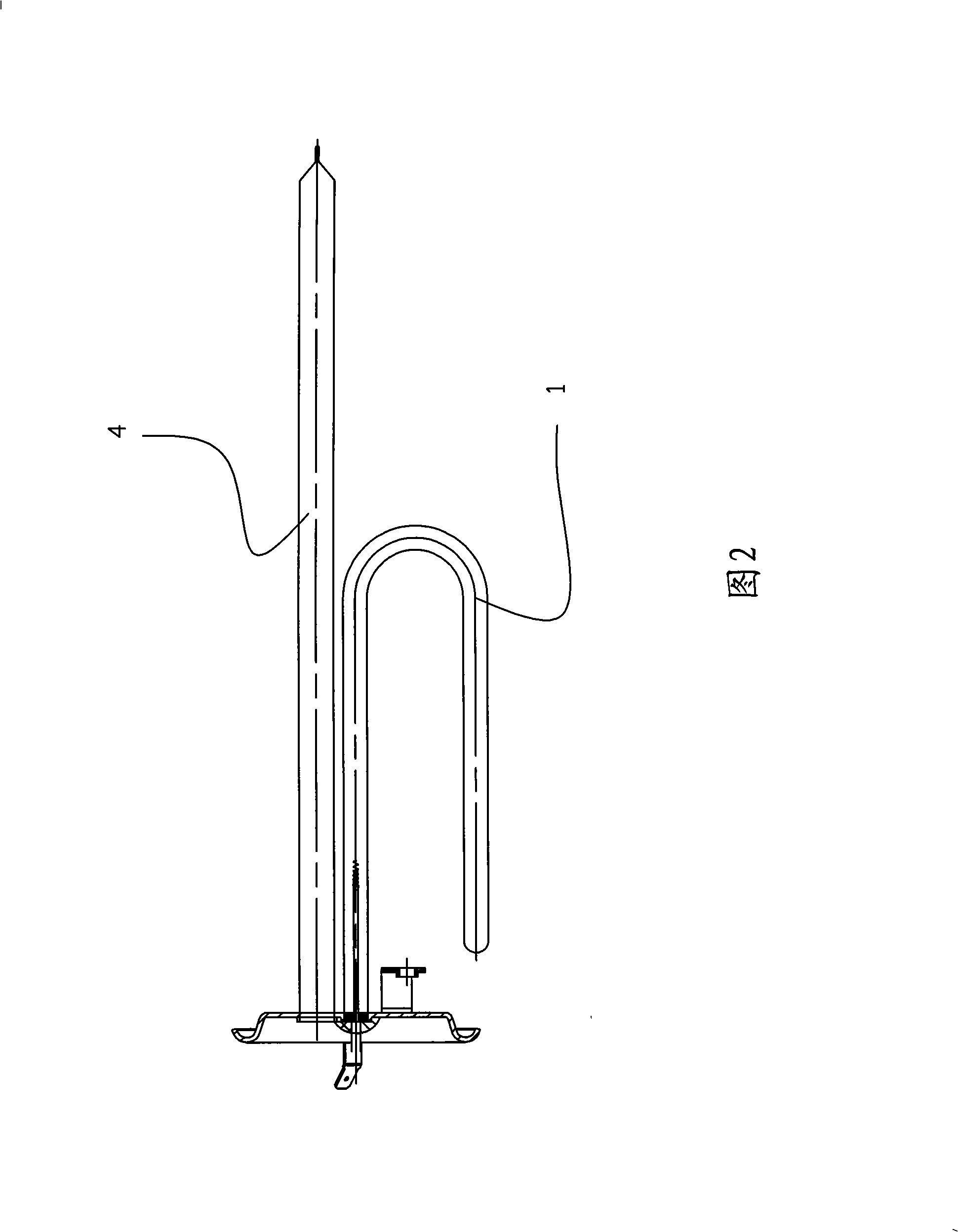

[0022] Referring to Fig. 1, an electric heating tube assembly of the present invention includes a heating tube 1, and the heating tube 1 includes a metal tube 10, and an electric heating wire 12 is passed through an insulating and heat-conducting material 11 inside the metal tube 10, and the heating tube 1 The outer surface of the metal tube 10 is covered with a protective layer of enamel 2 . Wherein, the metal pipe 10 can be an iron metal pipe of a specific shape as shown in Figure 1, of course, the metal pipe can also be another shape as shown in Figure 2, and the two ends of the iron metal pipe are protruded with heating wires 12 Connect the lead terminal 13.

[0023] Further, in order to facilitate the installation of the heating tube assembly on the inner tank of the electric water heater, the heating tube 1 is installed on a flange 3. In addition, in order to detect the real-time temperature of the heated liquid at the same time, the temperature of the heating tube can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com