Plasma spraying method for improving fatigue performance of welded structure

A technology of fatigue performance and welding structure, applied in the field of ion spraying method, can solve the problems of reducing stress concentration and the effect is not very ideal, and achieve the effect of reducing stress concentration, improving fatigue performance and improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

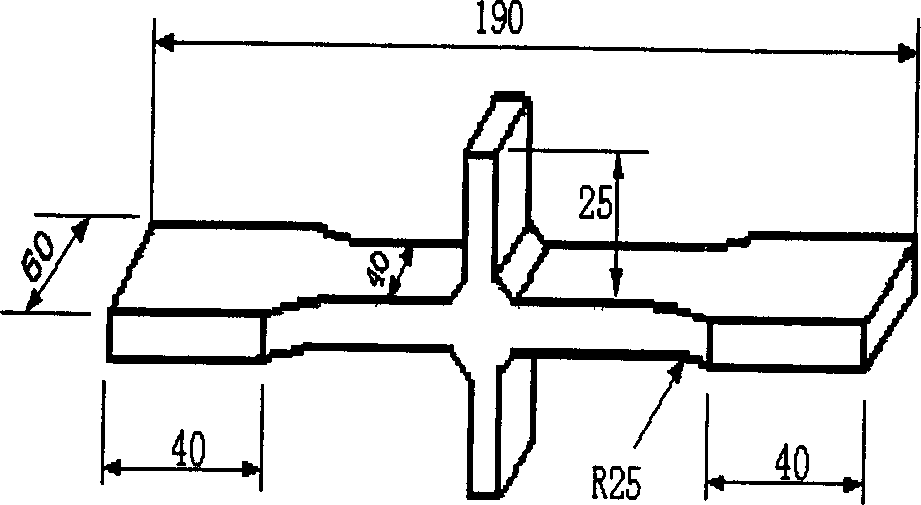

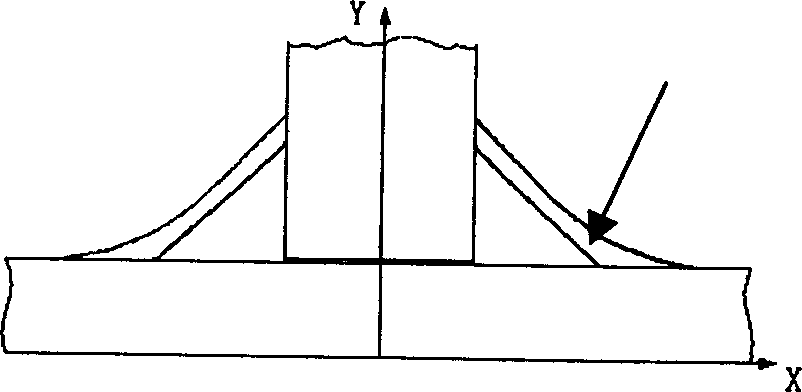

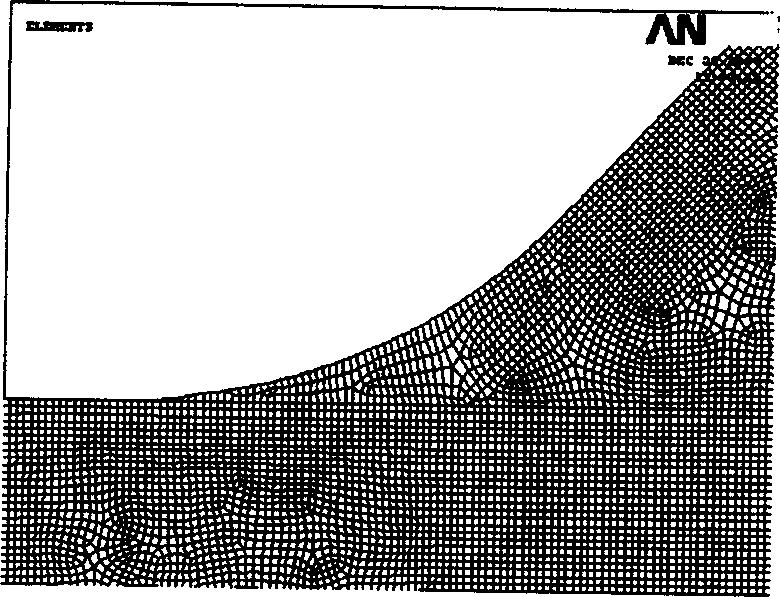

Embodiment 1

[0033] The welding method of the steel or aluminum material of the present invention adopts the prior art. The plasma spraying method for improving the fatigue performance of the welded structure of the present invention uses a plasma spraying process to spray a coating on the surface of a weld, and the spray coating includes the following steps: a. performing sand blasting on the weld of the sample before spraying. b. Plasma spraying the bonding bottom layer on the surface of the weld, the bottom layer material is selected from Ni / AL, Ni / Cr or McrALY, M is a transition metal Fe, Ni, Co or NiCo, and the thickness of the bottom layer is 0.03 ~ 0.07mm; preferably The nickel-clad aluminum bottom layer is used, and the thickness of the bottom layer is preferably 0.05mm. c. Plasma spray the powder on the surface of the weld to form a surface coating with a coating thickness of 0.8-1.2mm; the best plasma spray powder is nickel-clad aluminum and low-carbon steel powder. When plasma ...

Embodiment 2

[0035] The only difference from Embodiment 1 is that self-bonding primary powder is used as the plasma spraying powder.

Embodiment 3

[0037] The only difference from the first embodiment is that the composite powder is used as the plasma spraying powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com