Processing method for TC4 titanium alloy spiral groove screw tap

A processing method and titanium alloy technology, applied in the field of tool processing, can solve problems such as difficult processing, and achieve the effect of improving production efficiency and ensuring accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

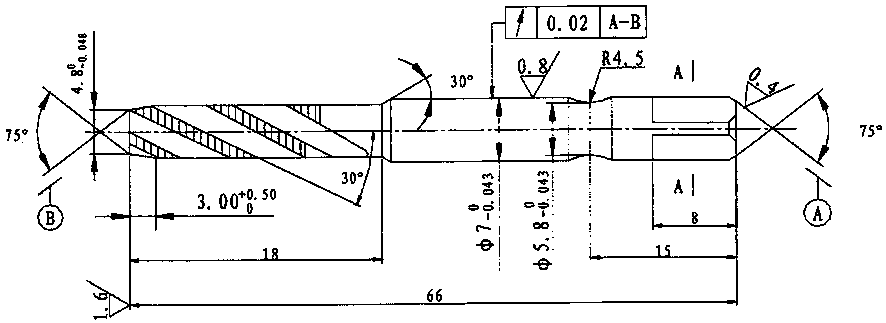

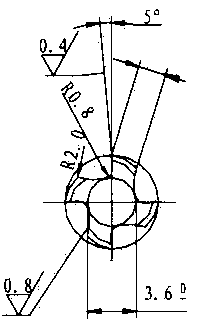

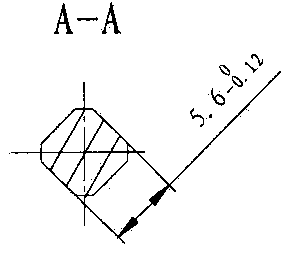

[0025] by Figure 1 to Figure 3 The TC4 titanium alloy spiral flute tap shown is an example, and its processing method includes the following steps:

[0026] (1) Cutting process: cutting according to the diameter and length of the tool, the diameter of the wool is Φ7mm, and the total length is 74mm;

[0027] (2) Rough turning process: both ends of the wool are lengthened by 4mm and the top is reversed, the tail shank 2 is left 0.3-0.4mm, the outer circle of the thread and the tooth shape are each left 0.4-0.5mm, the cutting edge is left 0.4mm, and the thick taper is engraved one;

[0028] (3) Finish turning process: 1 car at the rear to Φ5.6mm, 2R4.5Φ5.8 to the tolerance requirement for the tail handle of the finish car, and the tail handle 2 is a smooth transition to avoid scratching the workpiece to be processed;

[0029] (4) Milling process: Milling the tail square 1 to the required size, keeping the vertical symmetrical center;

[0030] (5) Milling process: Milling spir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com