Precise forging method for CoCrMo alloy artificial joint

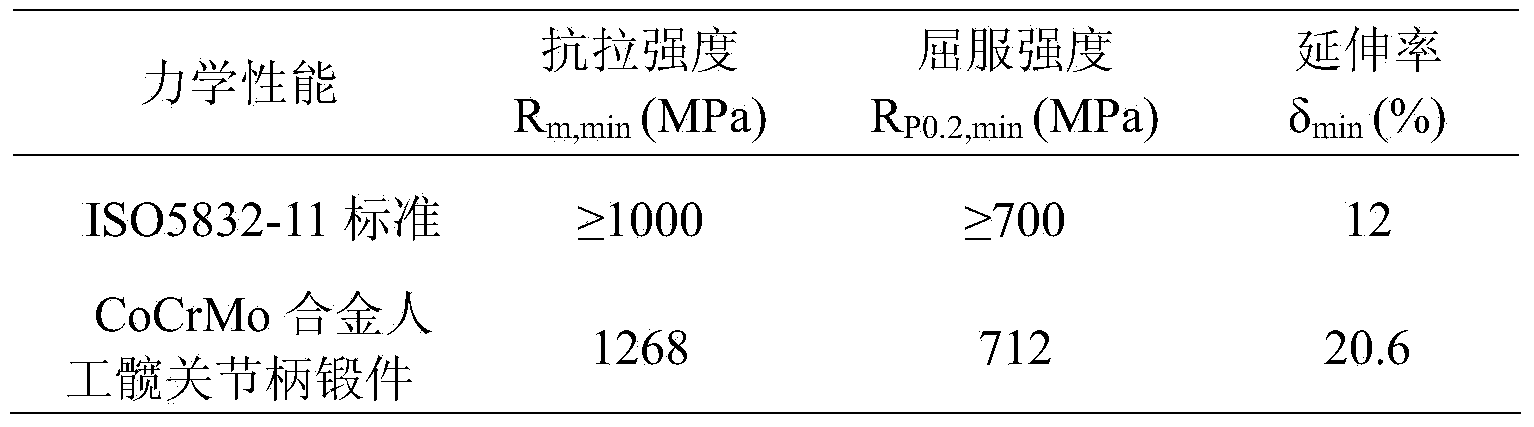

An artificial joint and precision forging technology, applied in the field of metal forging, can solve problems such as forging cracks and filling dissatisfaction, achieve the effects of reducing deformation resistance, improving strength and plasticity, and avoiding forging cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The chemical composition and mass percentage of this alloy are: Cr26.0~30.0%, Mo5.0~7.0%, C≤0.35%, Ni≤1.0%, Fe≤0.75%, Mn≤1.0%, Si≤1.0%, N≤0.25%, the balance being Co, characterized in that: the steps of the method are:

[0021] ⑴Choose Φ30mm CoCrMo alloy rods, blank them with a lathe or band saw, and make blanks by machining. The surface roughness is required to be 1.6. Check the surface quality of the blanks. Remove the defects and ensure that there is no dirt on the surface of the billet;

[0022] ⑵Heat the resistance furnace to 1000 ℃ ~ 1050 ℃, put in the billet, wait for the resistance furnace to reach the temperature again, keep it warm for 30 minutes, take out the billet one by one and bend it on the hydraulic press, after air cooling to room temperature, blow sand, polish the surface, remove Defect pit, fold, crack defect;

[0023] (3) Put the billet into the resistance furnace when it is heated to 1050°C-1100°C, and keep it warm for 30 minutes after the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com