Sublevel-open-stoping-method pressure-relief stoping method for high-dipping medium-thick ore body

A technology of thick ore body and steep inclination, which is applied in the field of staged open-field method for pressure relief and mining of steeply inclined medium and thick ore bodies, can solve the problem that the layout of transportation roadway cannot meet the engineering needs, increase the amount of mining quasi-engineering and related costs and influences. problems such as the stability of the roadway of the mining system, to achieve the effect of improving the mining efficiency, promoting the secondary adjustment and balance, and improving the blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

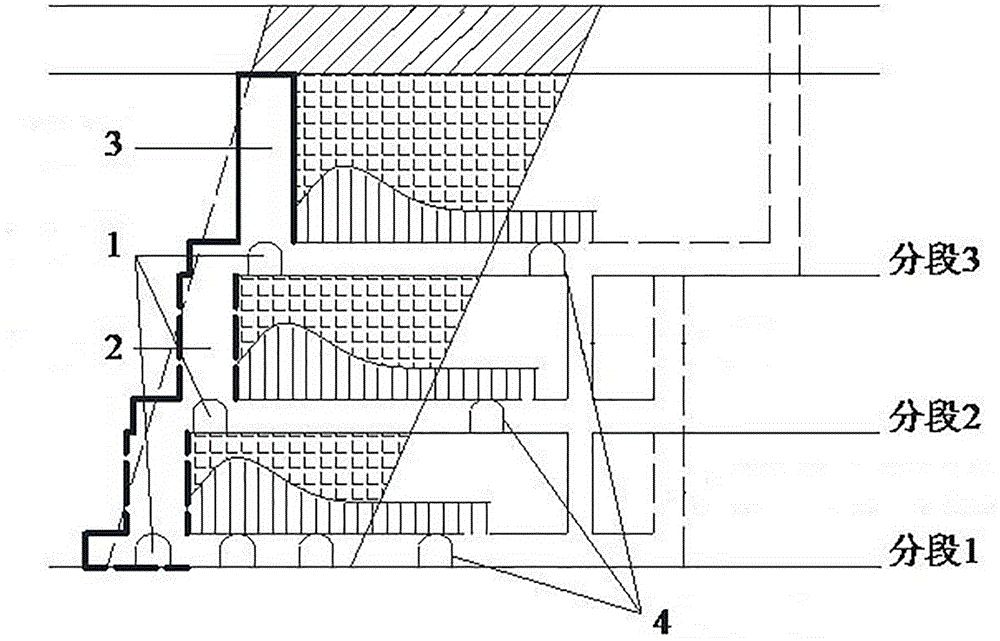

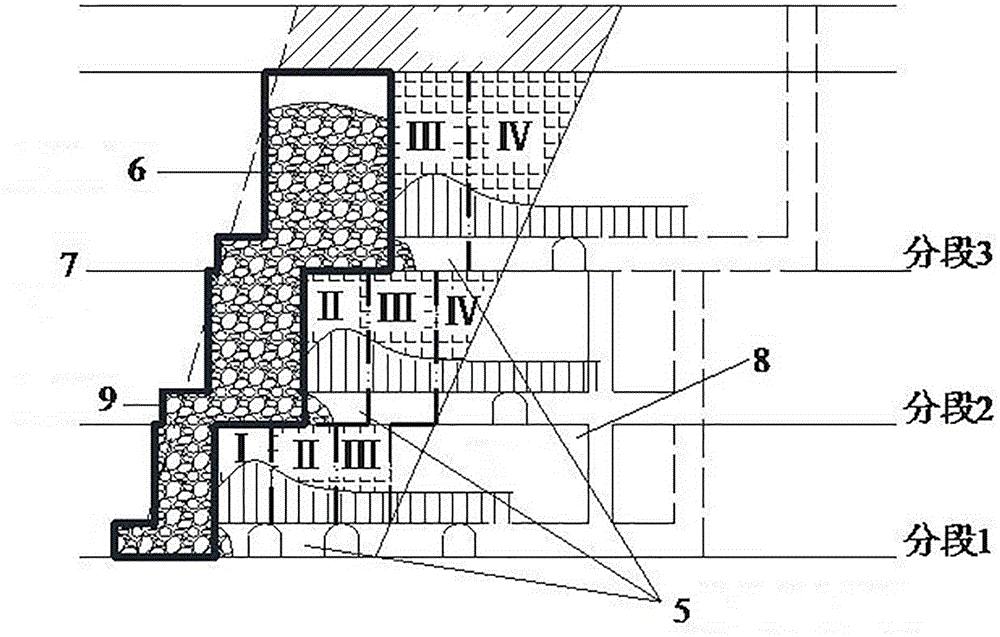

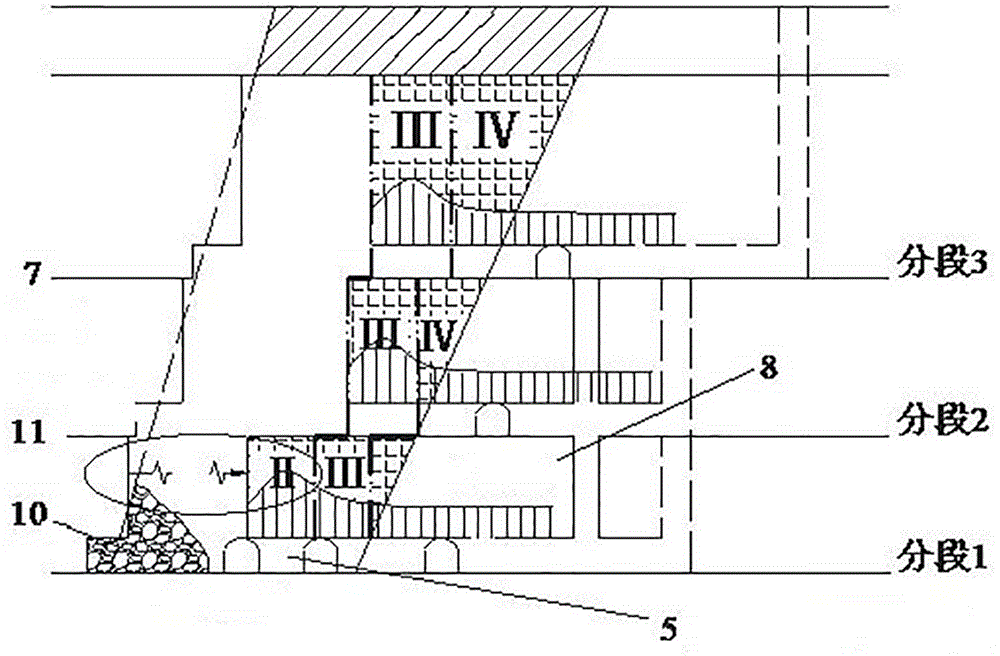

[0036] Such as Figure 1-3 Shown, a kind of sharply inclined medium-thick ore body subsection open-field method pressure relief mining method, the method is carried out according to the following steps:

[0037] Step 1: Arrange the cutting entry 1, the cutting patio 2 and the transportation roadway 4 in the ore body, take the cutting entry 1 as the working space, and drill an upward fan-shaped mid-deep vertical to the axis of the cutting entry 1 in the cutting entry 1 The blast hole, with the cutting patio 2 as the free surface, forms the cutting vertical groove 3 after blasting in stages;

[0038] Step 2: divide the ore body into 3 segments in the vertical direction of the ore body;

[0039] Step 3: In each segment of step 2, divide the ore body into several stopes along the ore body direction;

[0040] Step 4: During the stope recovery p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com