Collodion mop cleaning barrel

A collodion mop and cleaning bucket technology, applied in the field of sanitary cleaning appliances, can solve problems such as inability to squeeze water, shorten service life, and deformation of the collodion head, and achieve the effects of simple and reasonable structure, prolonging service life, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

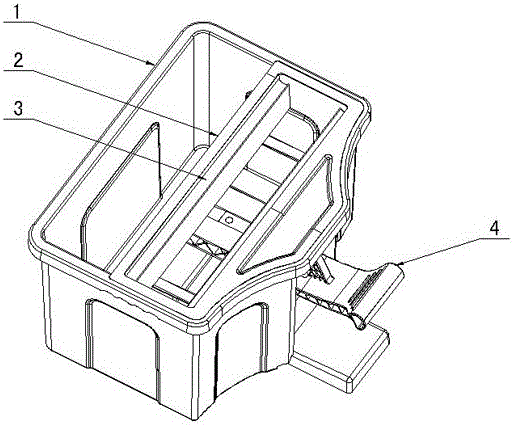

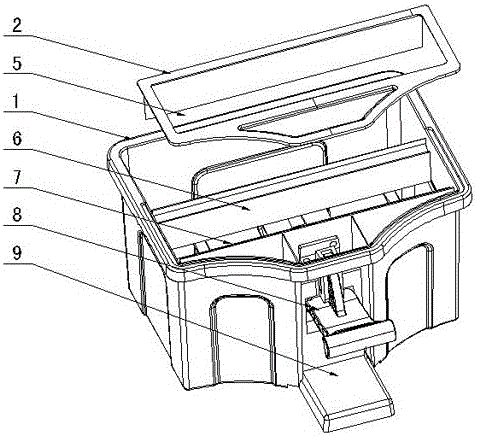

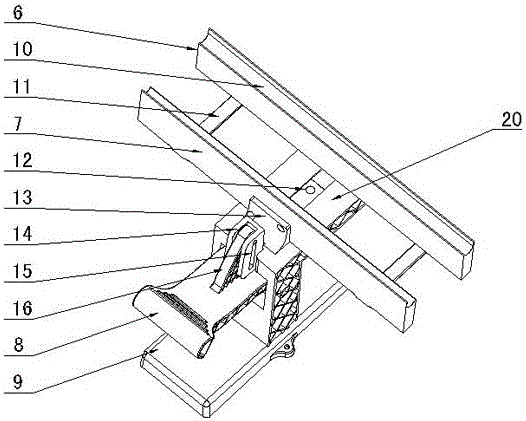

[0018] figure 1 , figure 2 , image 3 and Figure 5 Shown, for the present invention creates and adopts the concrete embodiment of the collodion mop cleaning barrel of the first kind of water squeezing scheme, it comprises the barrel body 1 that is used for collodion head cleaning, the base 9 that is fixed on the barrel body 1, described The base 9 is provided with a water squeezing device 3 and a driving device 4. The water squeezing device 3 includes a water squeezing fixed plate 7, a water squeezing movable plate 6, and a guide rail connecting rod 12. The upper part of the base 9 is provided with an expansion part 20 to expand The guide rail groove 19 is provided on the part 20, the guide rail connecting rod 12 is slidably arranged on the guide rail groove 19, the water squeezing fixed plate 7 is fixed on the expansion part 20 through the fixed plate seat 13, and the water squeezing movable plate 6 passes through the movable plate seat 18 Be fixed on the guide rail conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com