Patents

Literature

49results about How to "Accuracy has no effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

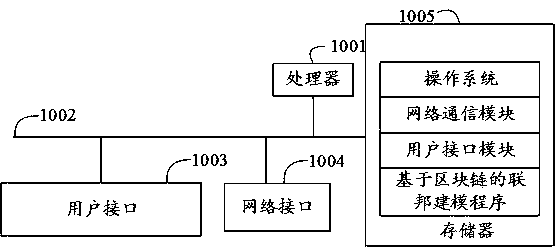

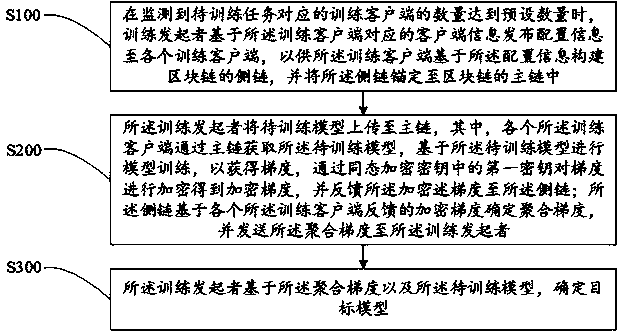

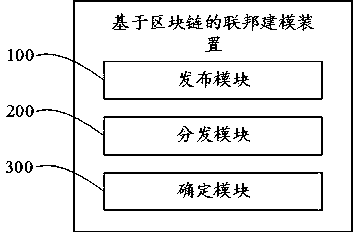

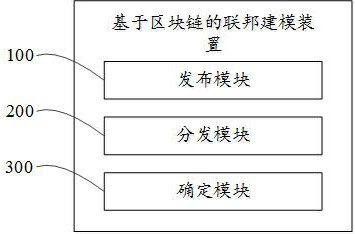

Federated modeling method, device and equipment based on block chain, and storage medium

ActiveCN111552986AAccuracy has no effectAccuracy impactDigital data protectionNeural architecturesModelSimPrivacy protection

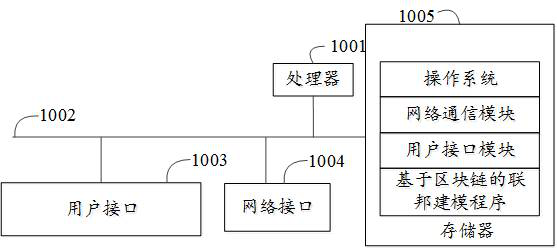

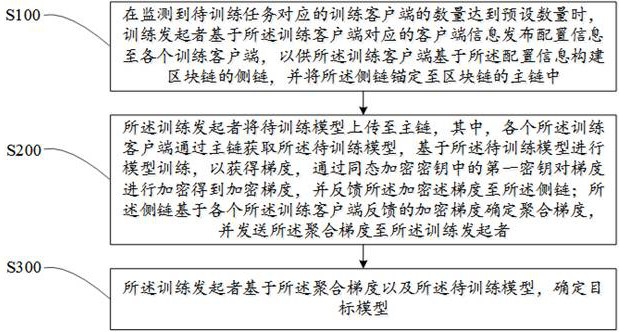

The invention discloses a federated modeling method, device and equipment based on a block chain, and a storage medium. The method comprises the following steps: a training initiator issues configuration information to all training clients based on client information corresponding to the training clients when the number of the training clients is monitored to reach a preset number; the training initiator uploads a to-be-trained model to a main chain; and the training initiator determines a target model based on aggregation gradient and the to-be-trained model. Modeling of federated learning isrealized through the block chain; on the premise of protecting the privacy of federated learning data, the accuracy of federated learning is not affected, the training effect and model precision of federated learning are improved, model parameters such as gradients in transmission do not need to be modified, and the balance between privacy protection of the model parameters such as gradients andmodel convergence or model precision is achieved; and information leakage can be completely prevented, so the safety of data samples in federated learning is improved.

Owner:PENG CHENG LAB +1

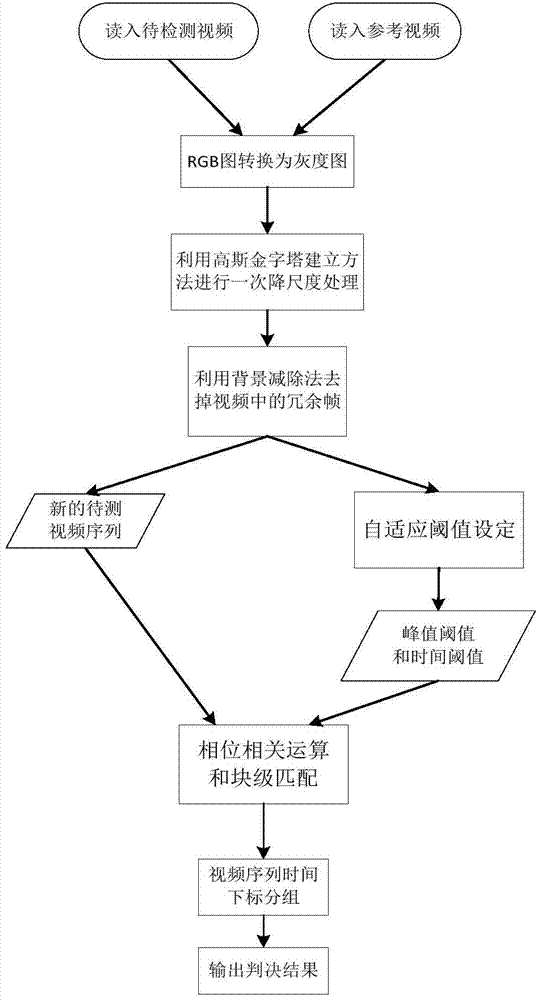

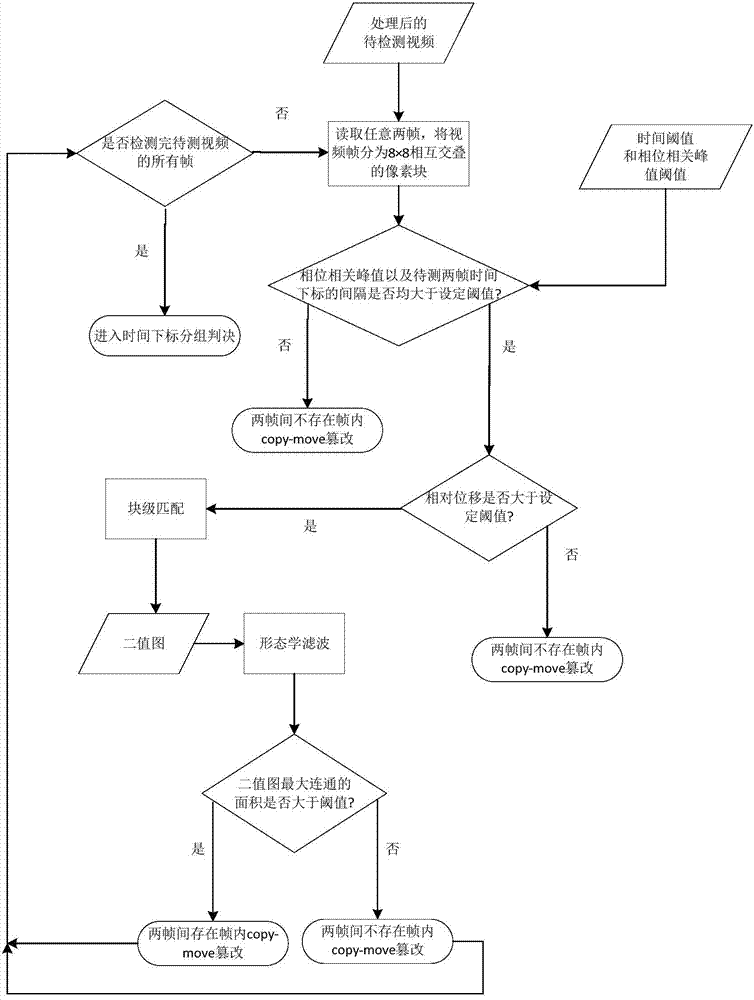

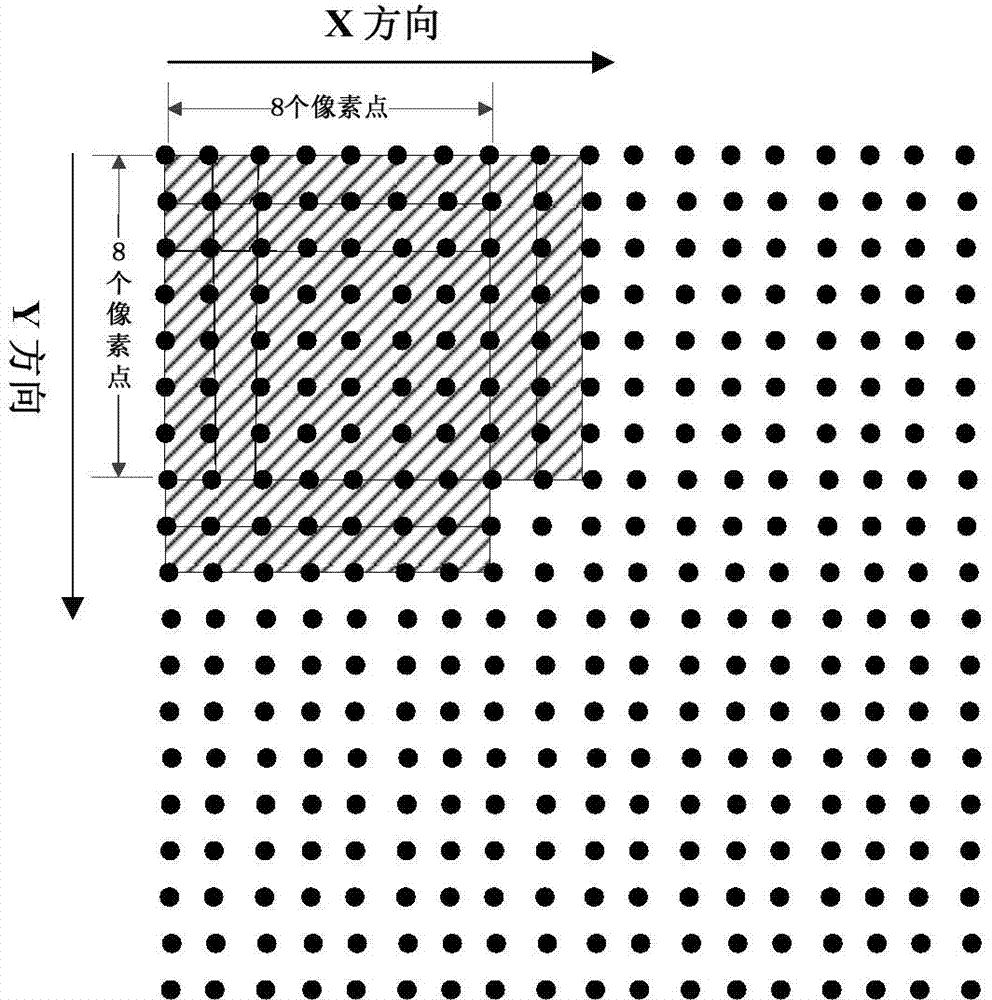

Video intra-frame copy-move tampering detection method based on space and time relevance

ActiveCN103945228AImprove robustnessAccuracy has no effectDigital video signal modificationPattern recognitionPhase correlation

The invention provides a video intra-frame copy-move tampering detection method based on space and time relevance. The video intra-frame copy-move tampering detection method comprises the steps that firstly, downscaling processing is conducted on a video frame according to an establishment method of an image Gaussian pyramid; then, a time threshold value and a peak threshold value are set in a self-adaptive mode through time relevance and space relevance of the content of a monitoring video respectively; suspicious frame pairs which may have intra-frame copy-move tampering are screened out through phase correlation and a detection method based on block matching, and a binary image which describes the position of a tampered area is obtained through calculation; finally, suspicious frames are grouped through the time threshold value and then final judgment is carried out. Compared with similar algorithms, the video intra-frame copy-move tampering detection method based on space and time relevance has the advantages that the operation time is shortened greatly, and the robustness of an algorithm on Gaussian noise is enhanced. When the tampered area is described through the binary image, the operation of morphological filtering is added, interference caused by erroneous judgment points and noise points can be eliminated to a certain extent, and detection accuracy is improved.

Owner:SHANGHAI JIAO TONG UNIV

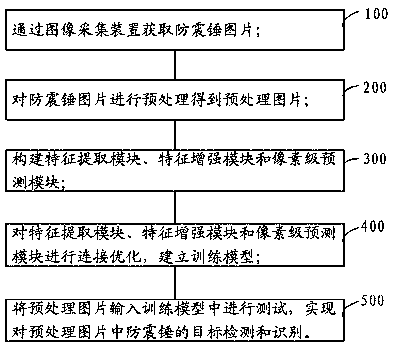

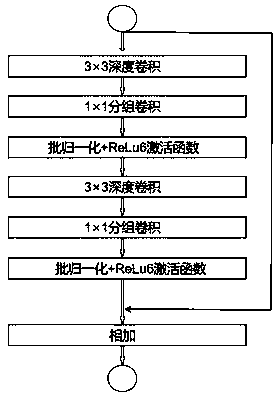

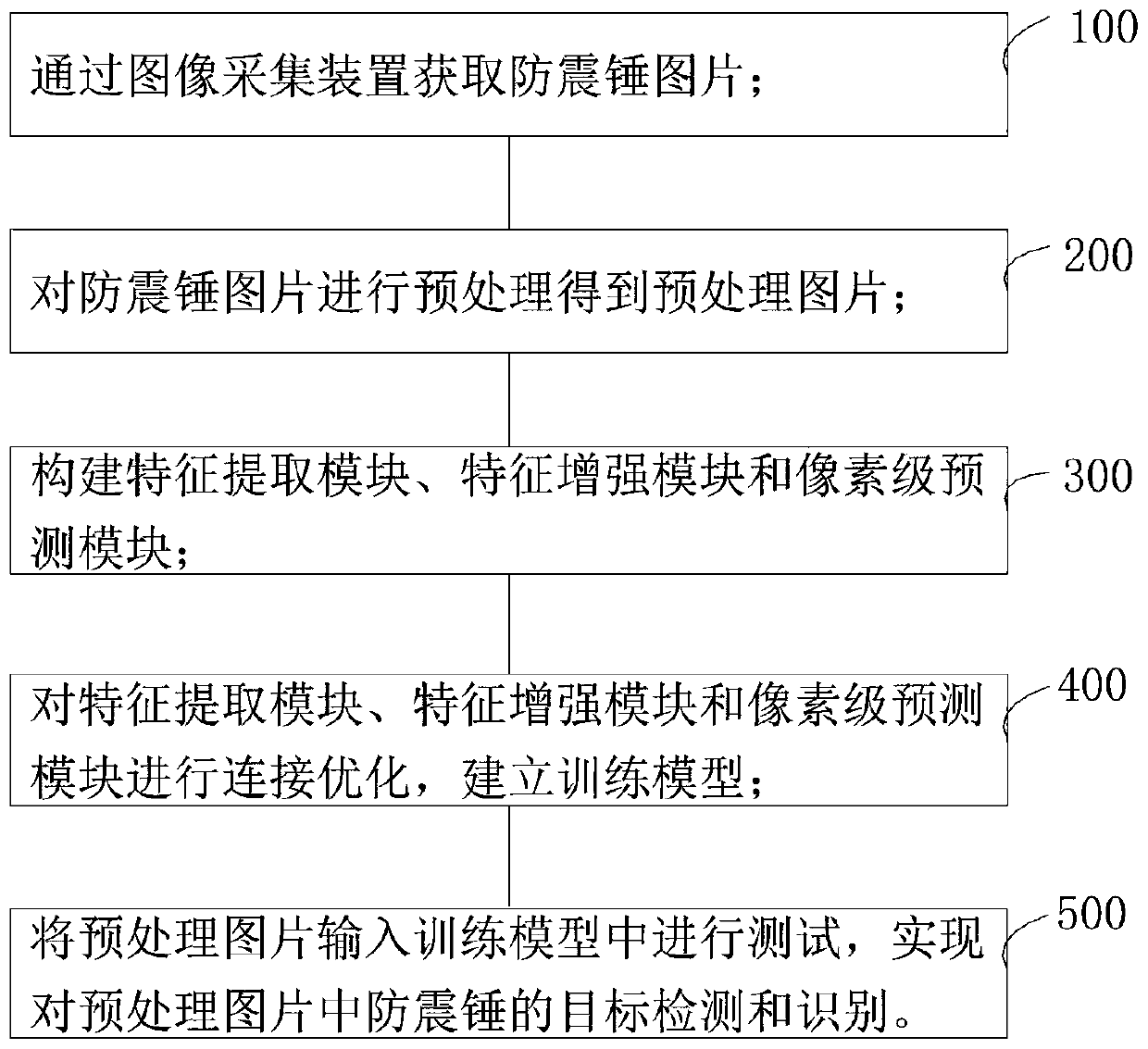

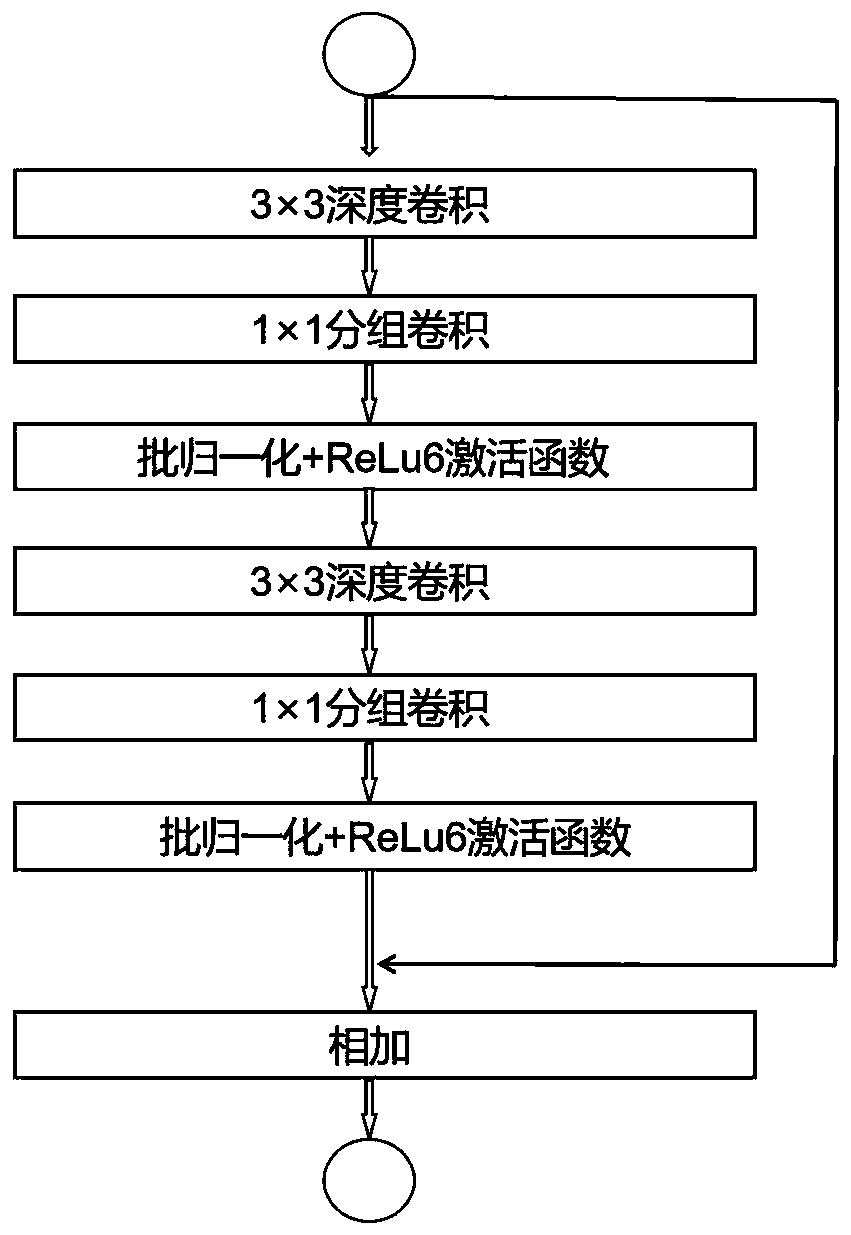

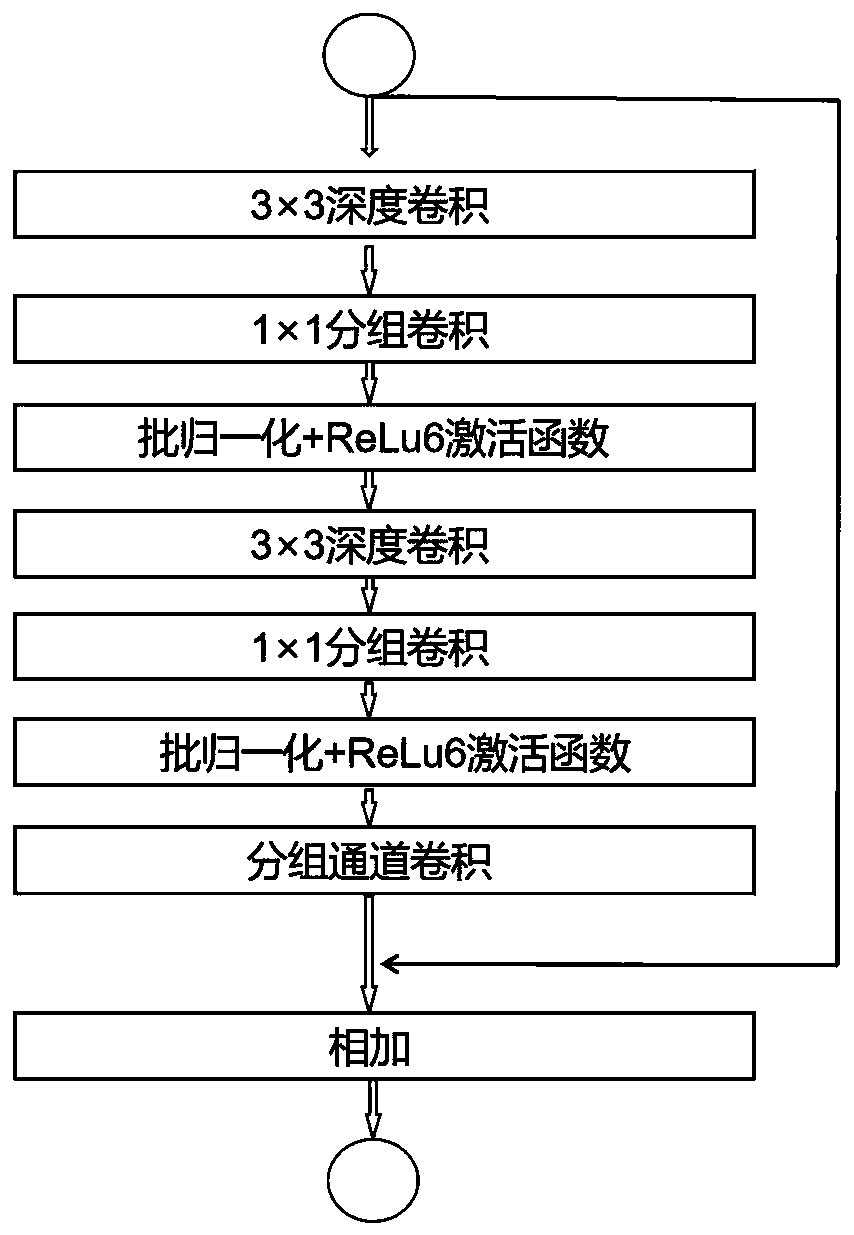

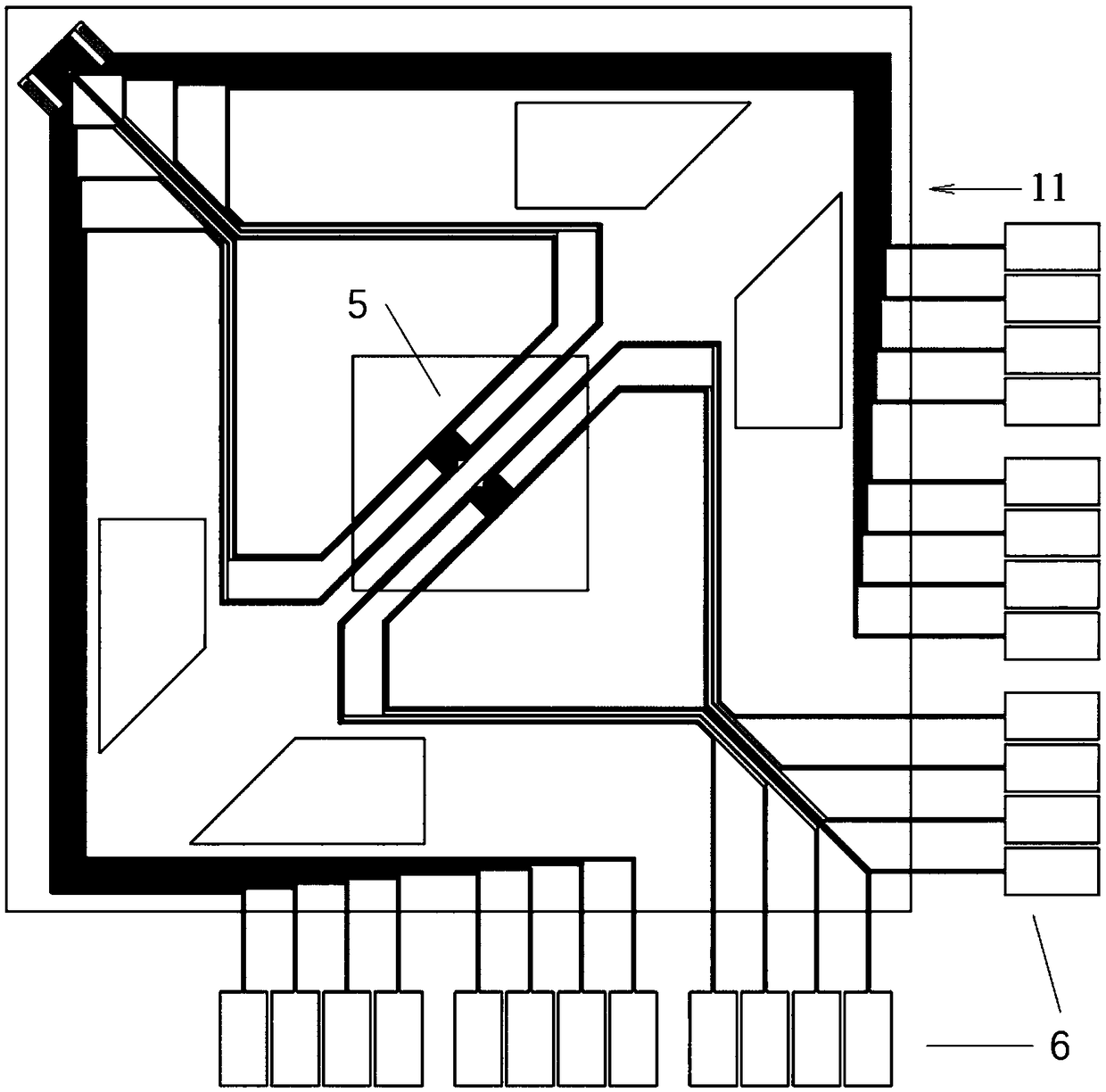

Target detection and defect identification method for stockbridge damper of power transmission line and device

PendingCN110378222ADetection speedImprove efficiencyImage enhancementImage analysisFeature extractionIdentification device

The invention discloses a target detection and defect identification method for a stockbridge damper of a power transmission line. The method comprises the following steps: acquiring a stockbridge damper picture through an image acquisition device; preprocessing the shockproof hammer picture to obtain a preprocessed picture; constructing a feature extraction module, a feature enhancement module and a pixel-level prediction module; performing connection optimization on the feature extraction module, the feature enhancement module and the pixel-level prediction module, and establishing a training model; and inputting the pre-processed picture into a training model for testing, thereby realizing target detection and identification of the shockproof hammer in the pre-processed picture. The invention also provides a target detection and defect identification device for the shockproof hammer of the power transmission line. According to the method and the device, the detection speed of a high-resolution picture is greatly improved; calculation is reduced to a certain extent, rapid and accurate shockproof hammer target detection and defect identification are realized, and the efficiency ofelectric power inspection work is improved.

Owner:NANJING NARI GROUP CORP +3

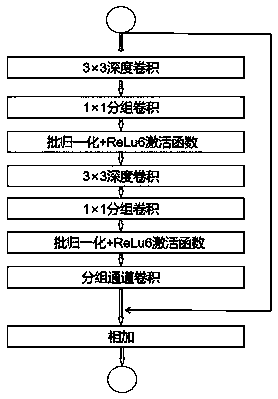

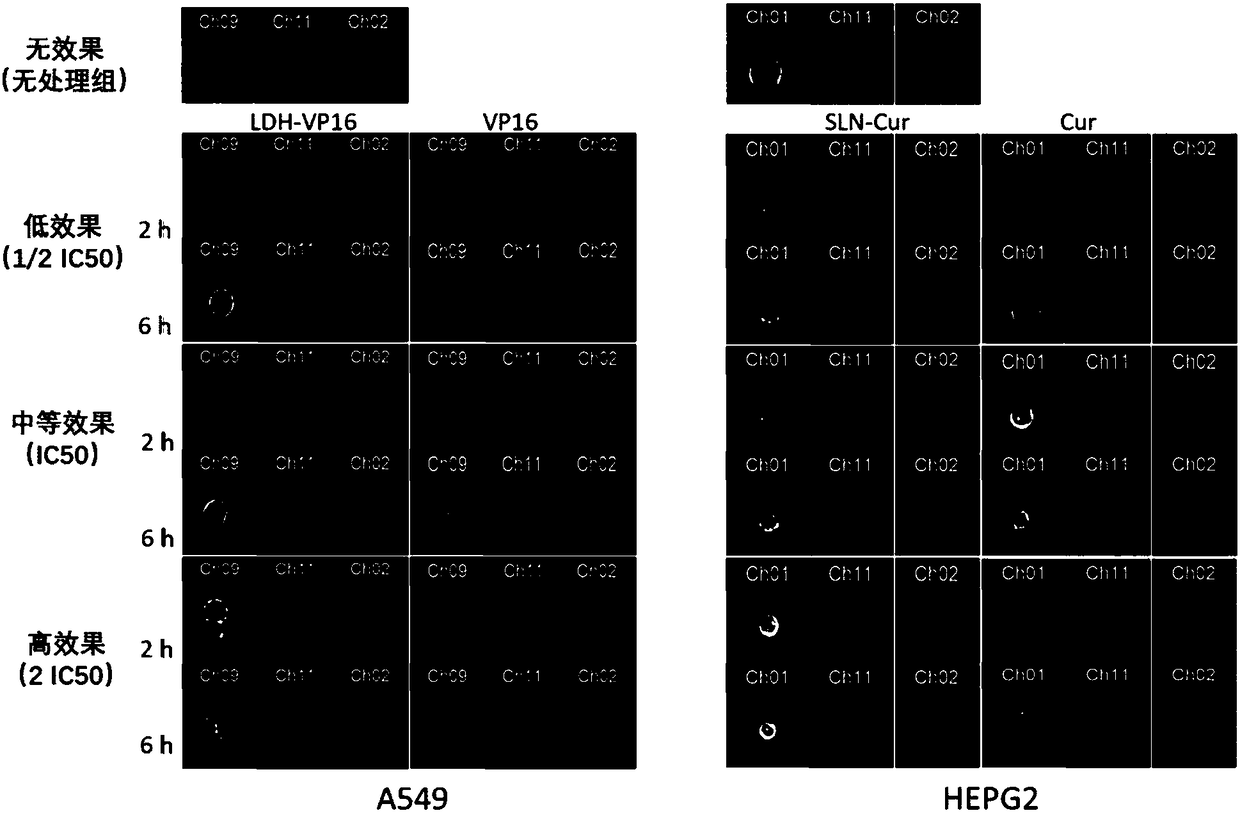

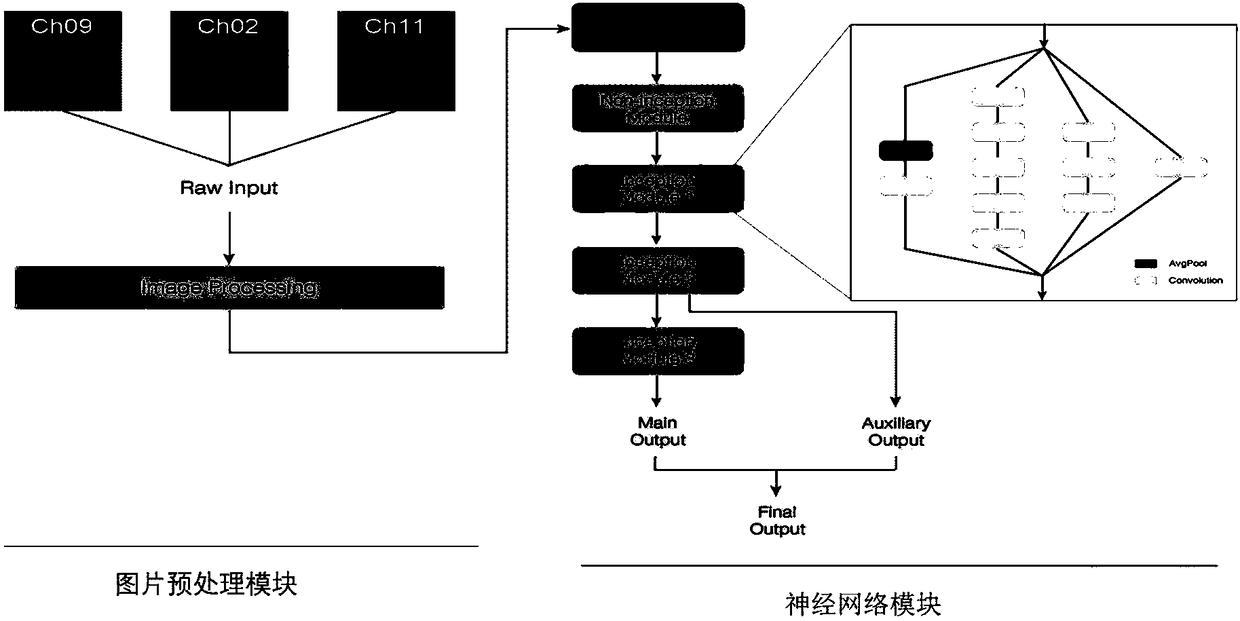

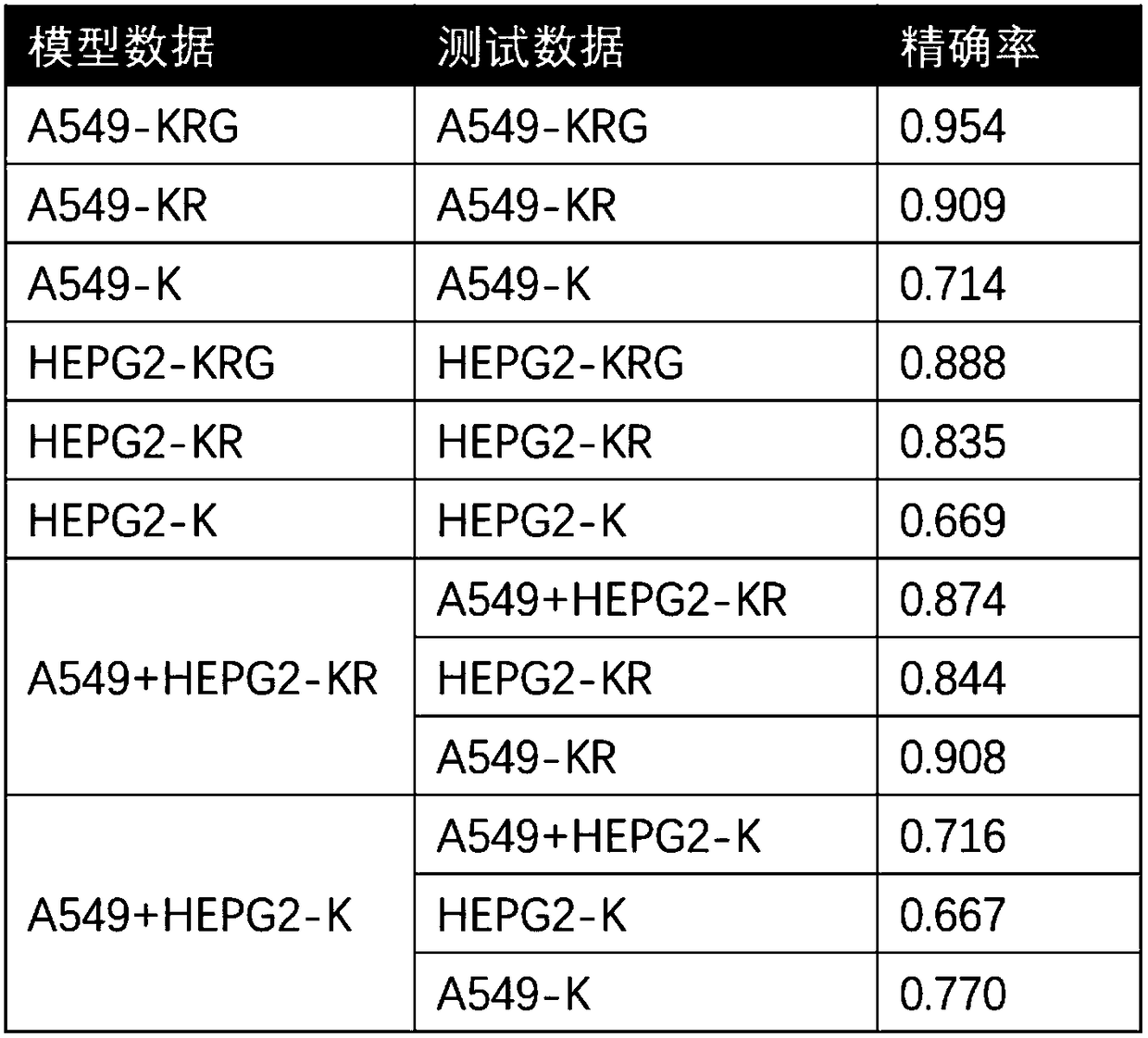

Quick and precise high-throughput drug screening system based on deep learning

ActiveCN108280320AAccurate assessmentWill not affect judgmentMolecular designCharacter and pattern recognitionAlgorithmTensor representation

The invention discloses a quick and precise high-throughput drug screening system based on deep learning. The drug screening system comprises a picture preprocessing module and a neural network module, wherein the picture preprocessing module comprises a channel merging module and a picture standardization module; the channel merging module merges different cell single-color channel pictures intothe multi-channel picture representation, wherein the merged picture tensors are represented as [H,W,C]; the picture standardization module standardizes the input multi-channel picture data into the tensor representation of [70,70,C]; the neural network module is connected with the picture standardization module, the input data of the neural network module is standardized picture tensors, and finally the trained neural network is subjected to final prediction classification prediction. The drug screening system DeepScreen based on deep learning has the advantages of being high in throughput, precise, efficient, fast, convenient, low in cost and resistant to interference, and has a worth-concerning practical and application prospect.

Owner:SHANGHAI TONGJI HOSPITAL

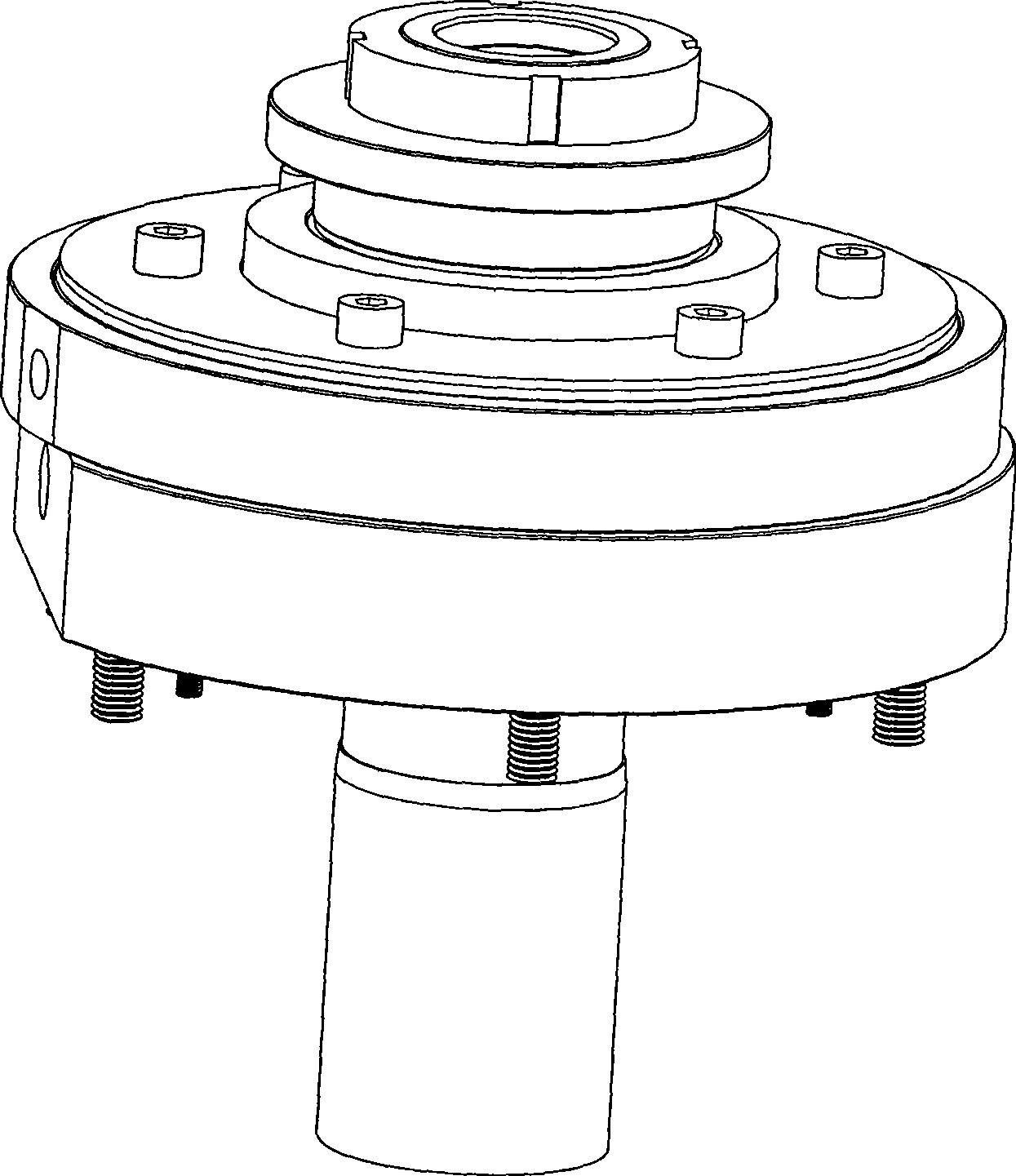

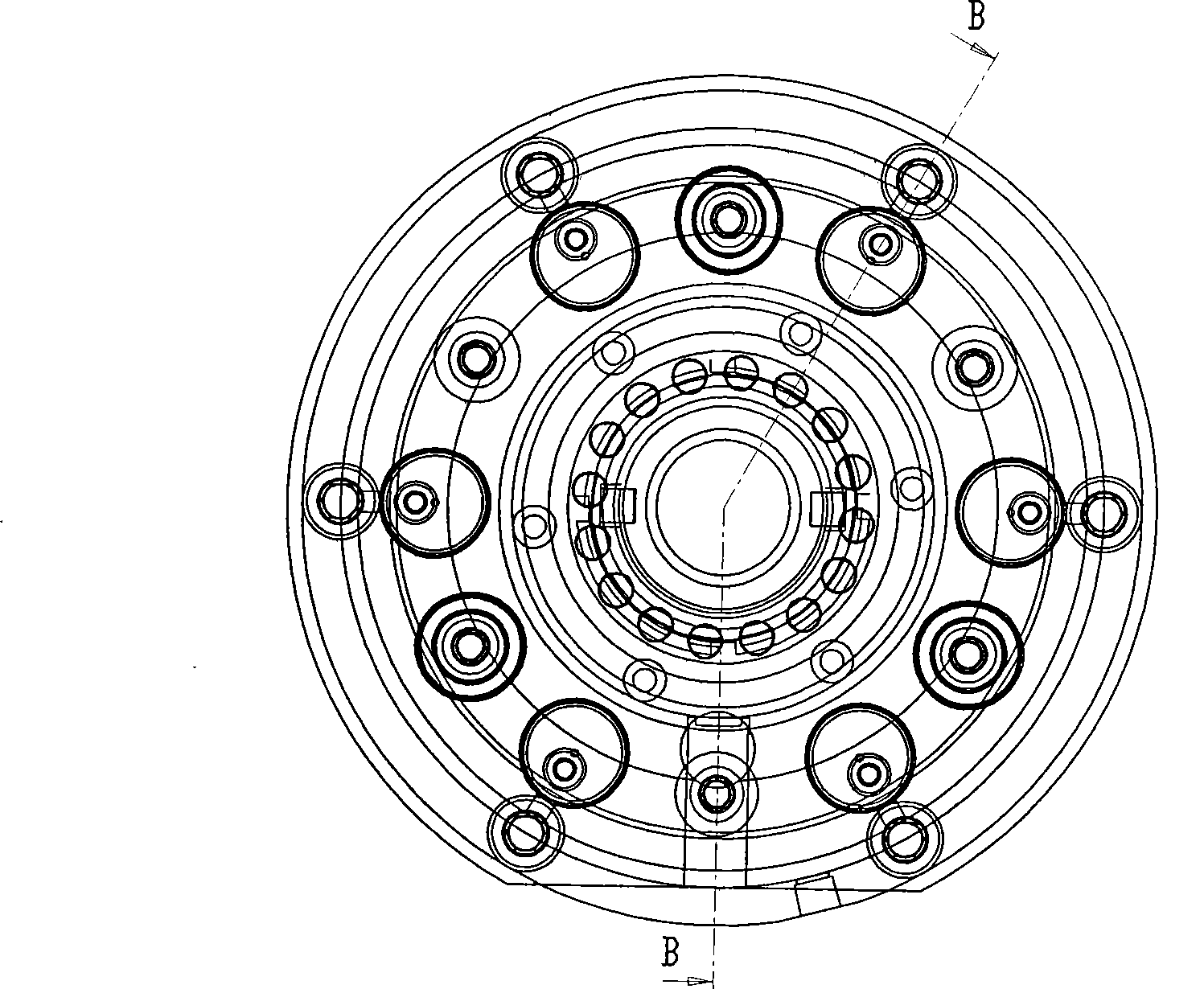

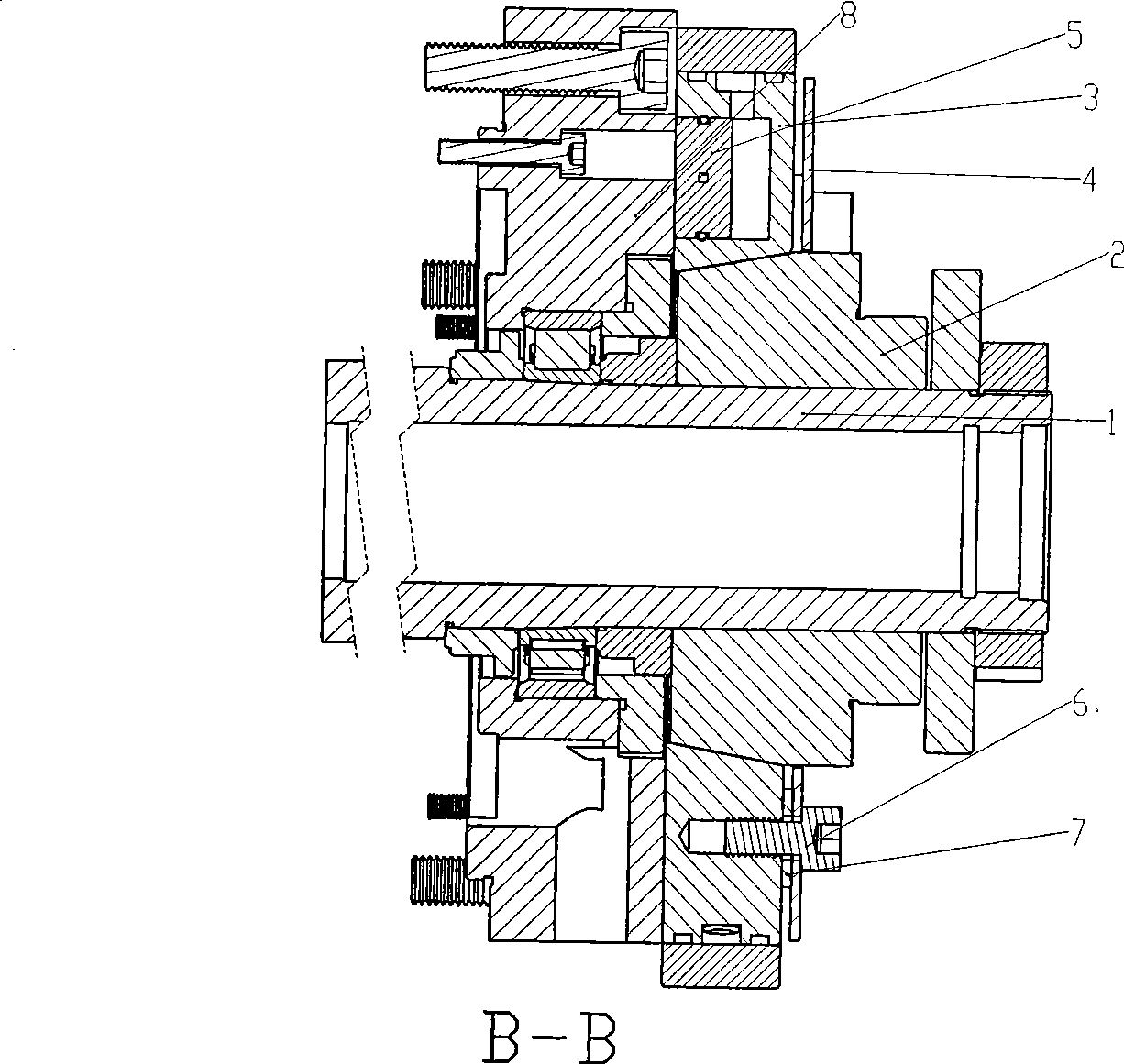

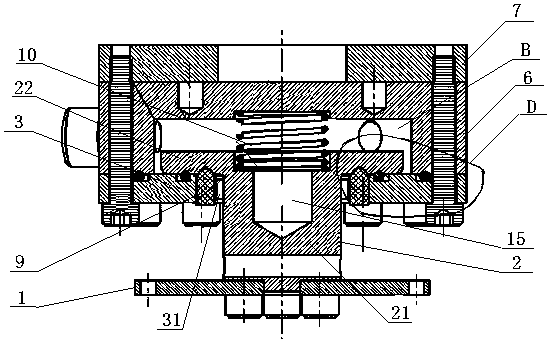

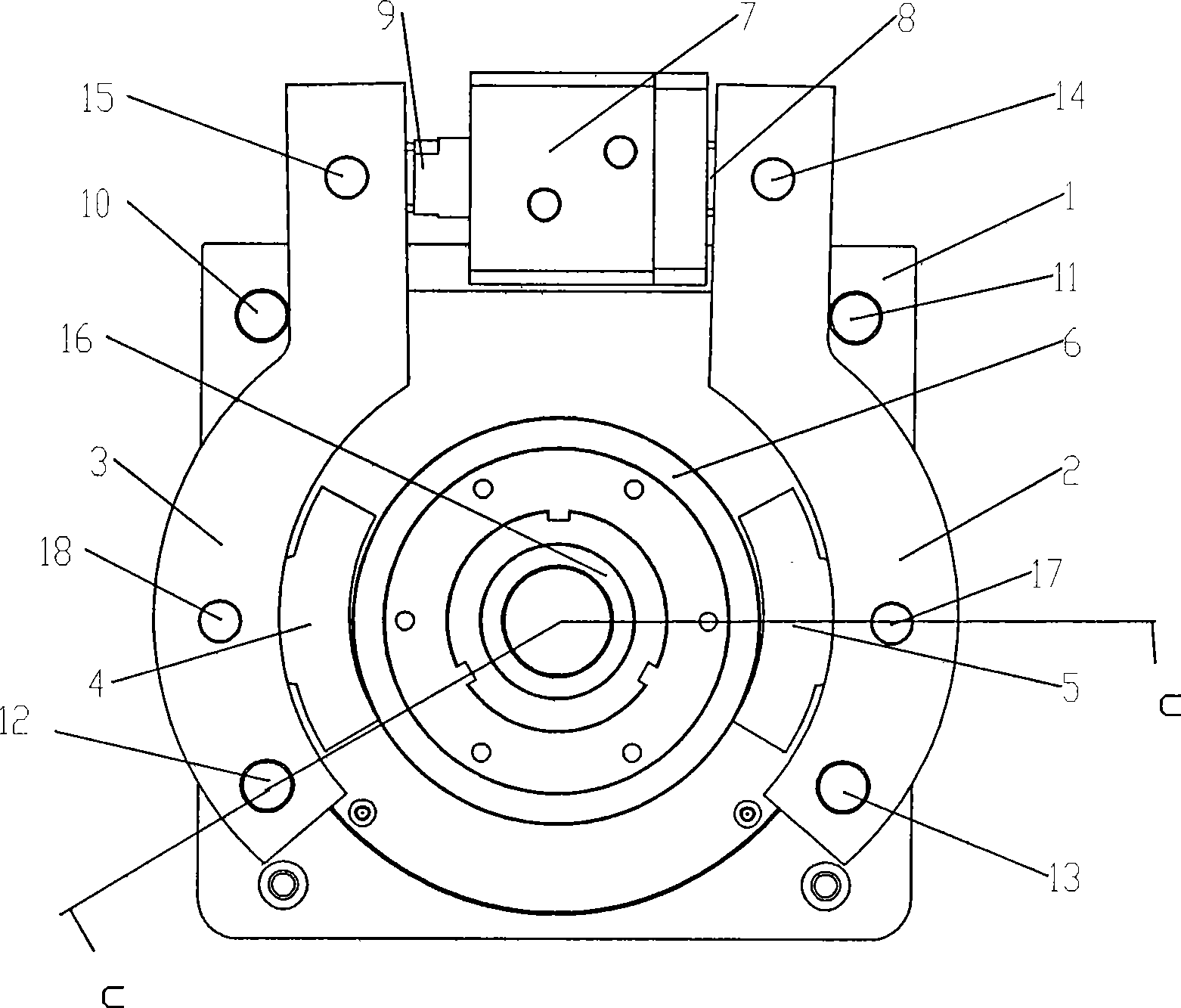

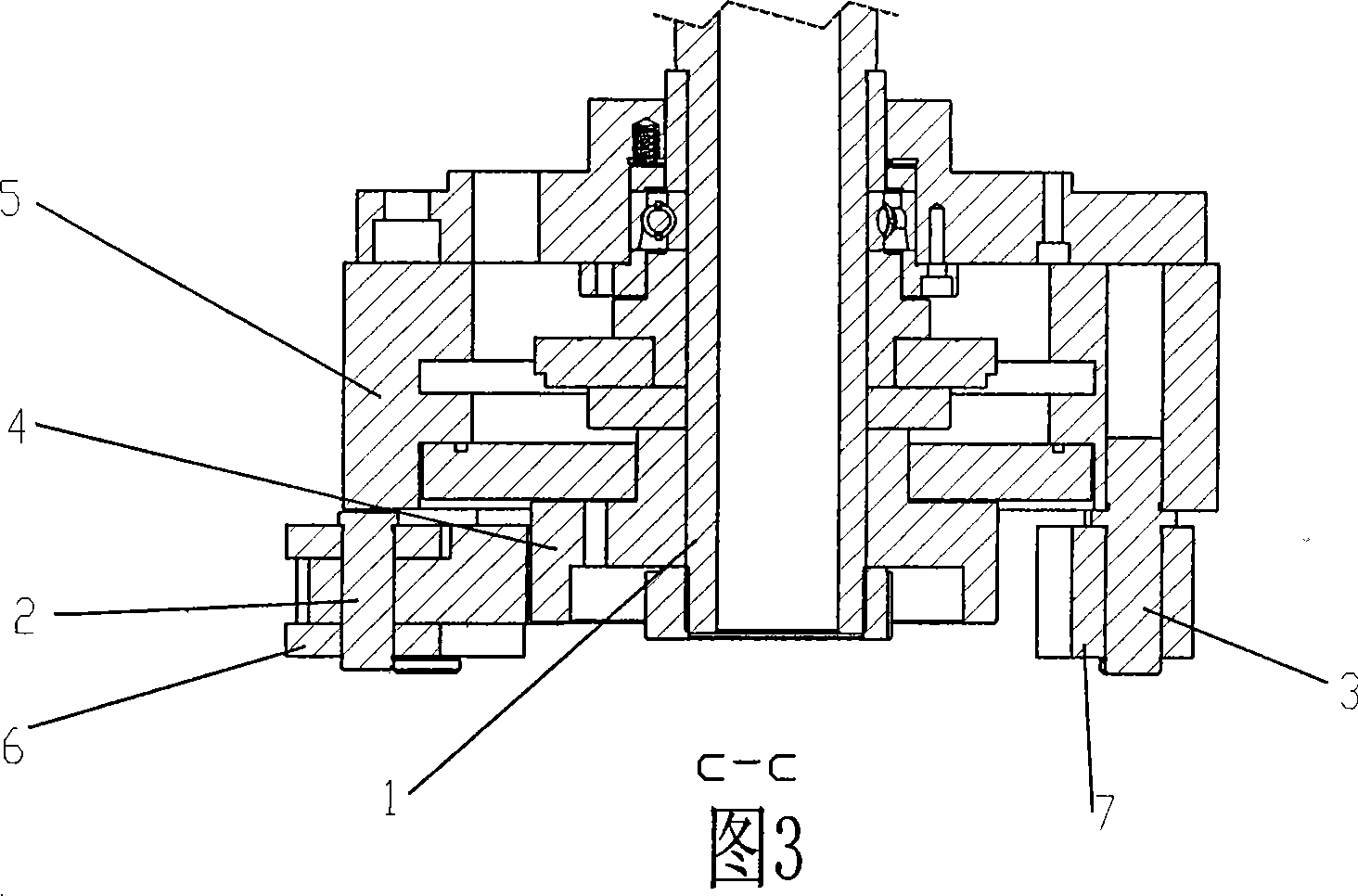

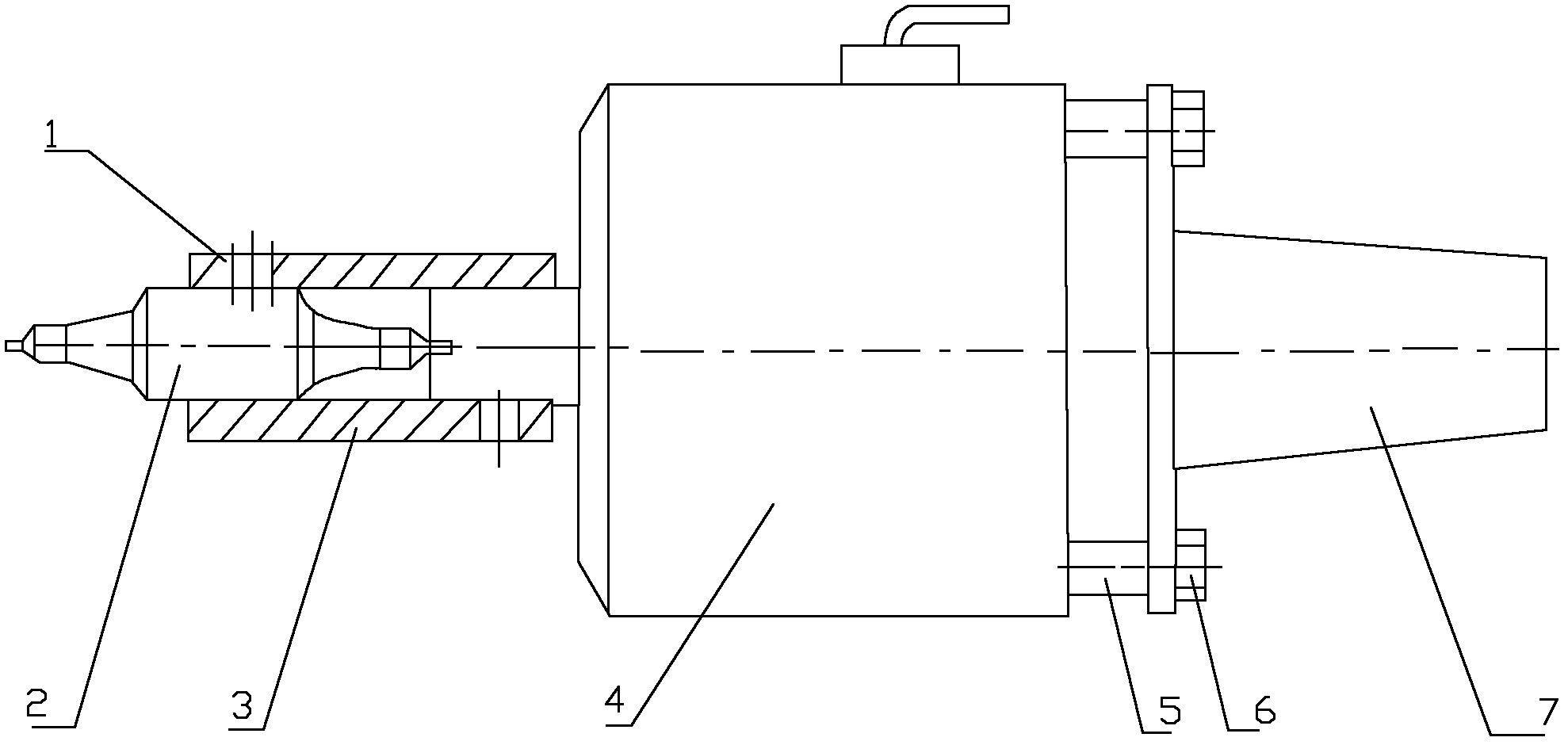

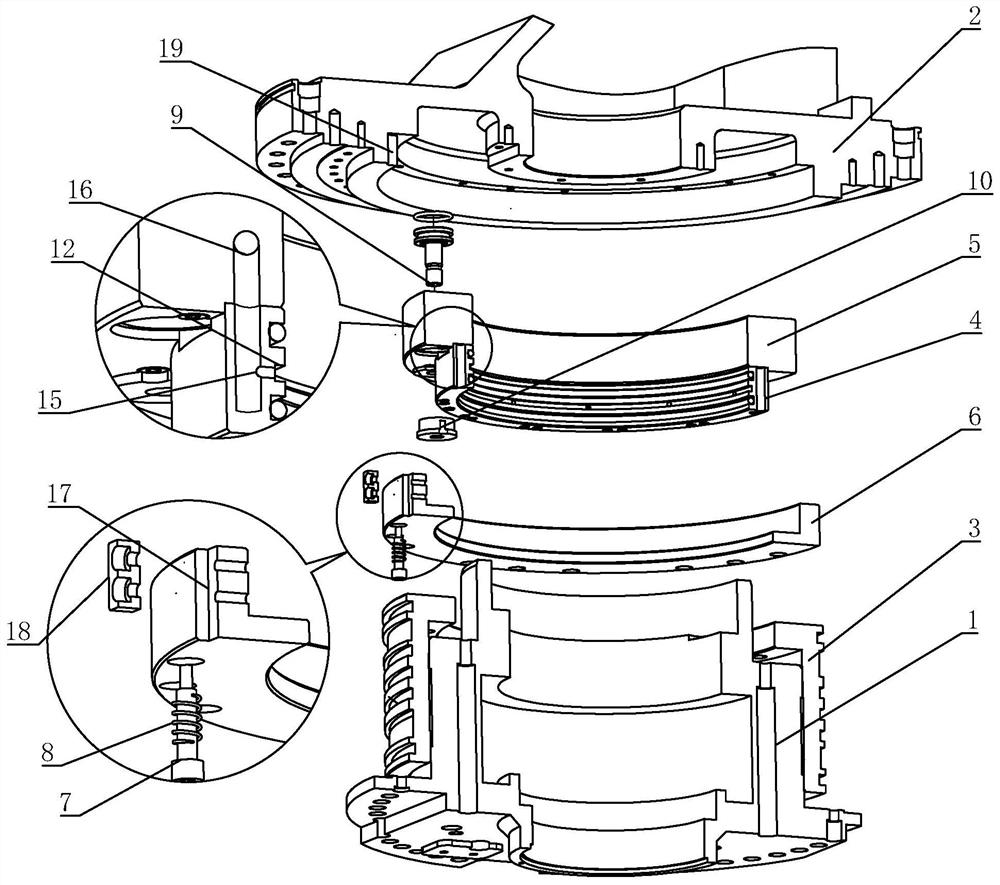

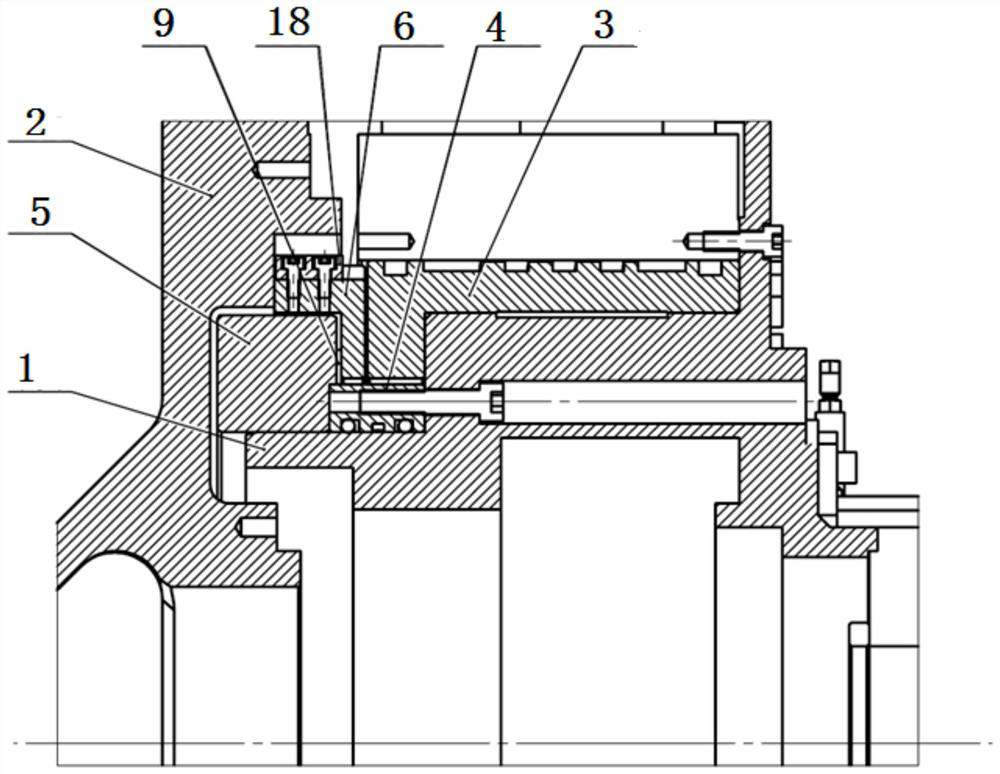

Apparatus for locking main shaft

The invention discloses a spindle locking device and relates to a precise spindle locking device. The spindle locking device consists of an internal expansion sleeve, an external expansion sleeve, a spring disc, a piston block and a fixed post, a fixing bolt and a fixing bolt. The internal expansion sleeve is fixed on a spindle and can rotate together with the internal expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve. Conical surfaces which are matched with each other are arranged between the internal expansion sleeve and the external expansion sleeve. The external expansion sleeve is sleeved on the internal expansion sleeve through the conical surfaces. The spring disc is sleeved on the internal expansion sleeve. The external expansion sleeve is positioned between a rear flange of the spindle and the spring disc. The spring disc is fixed with the rear flange through the fixed post and the fixing bolt. The spring disc and the external expansion sleeve are locked through the locking bolt. The piston block is arranged between the rear flange and the external expansion sleeve. Using the deformation characteristic of the spring disc and a taper locking mode, the locking device avoids any influence on the precision of the spindle when the spindle is locked and absolutely reliable locking is achieved, thereby ensuring the precision of processed parts, the precision of the spindle and the service life of the spindle.

Owner:GUANGZHOU WEIJIA MACHINE

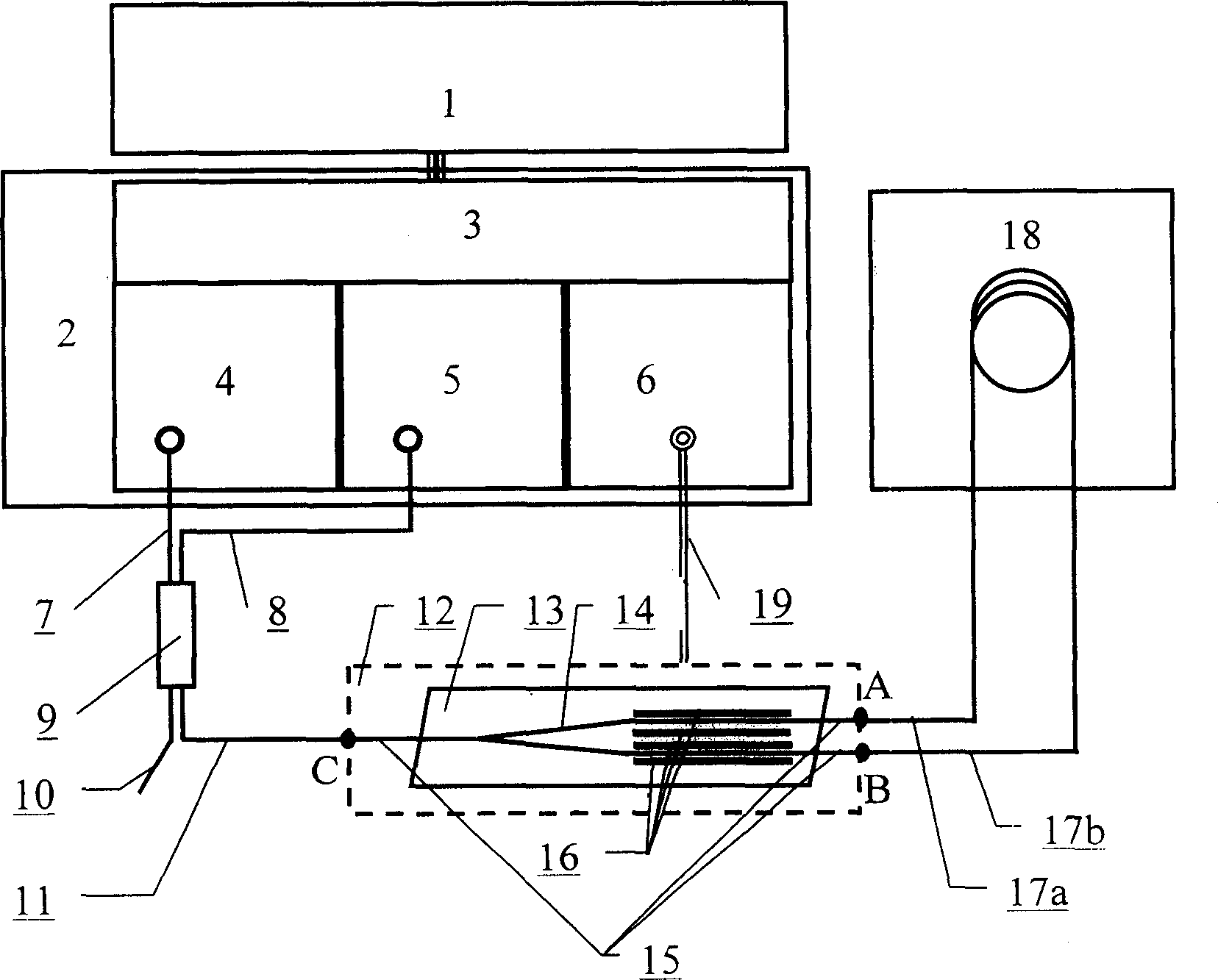

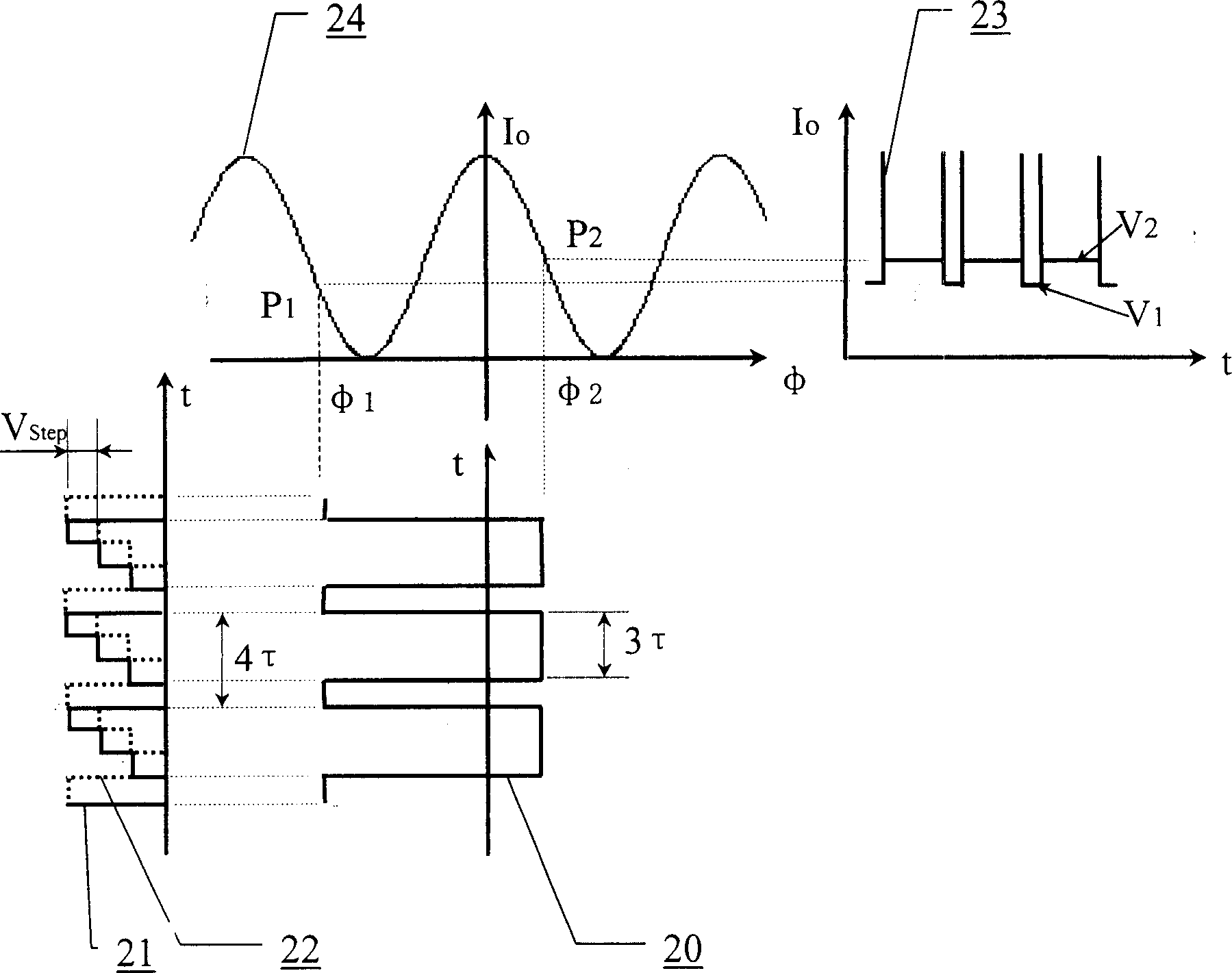

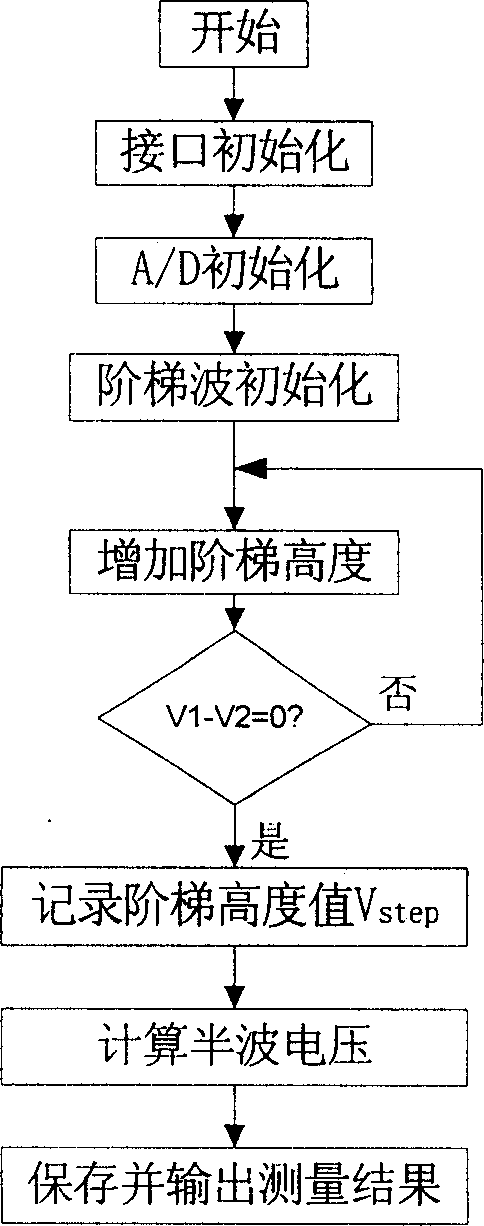

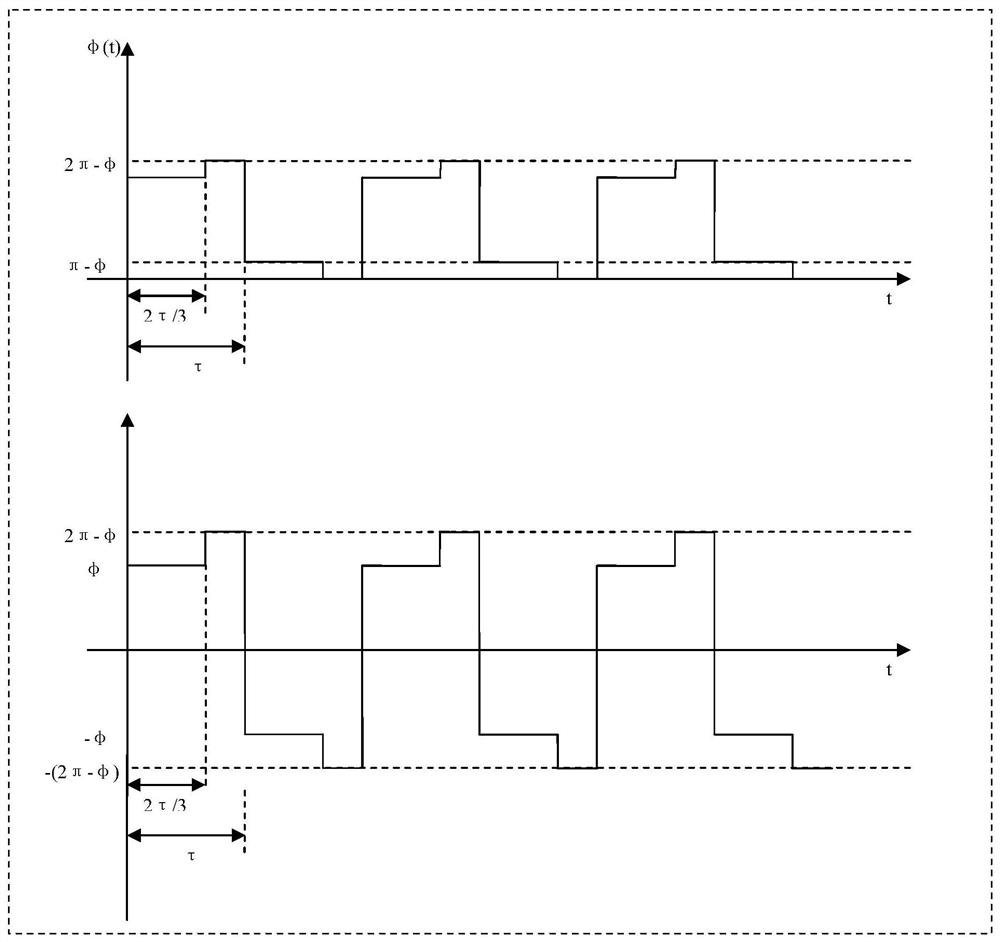

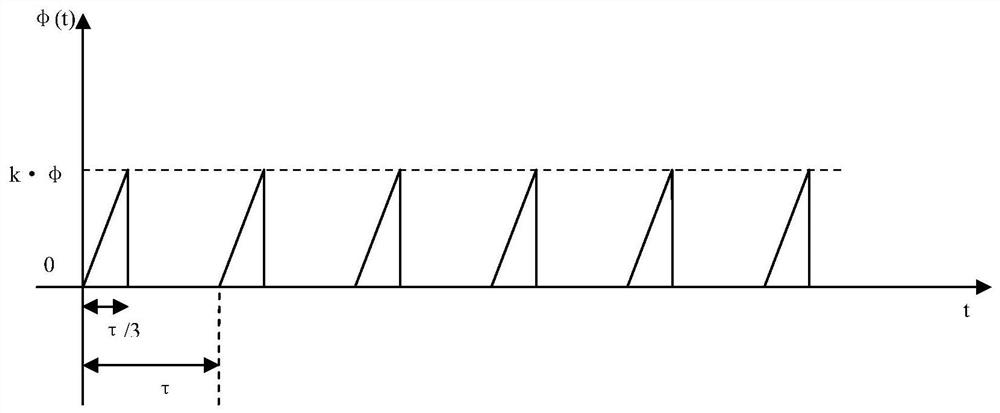

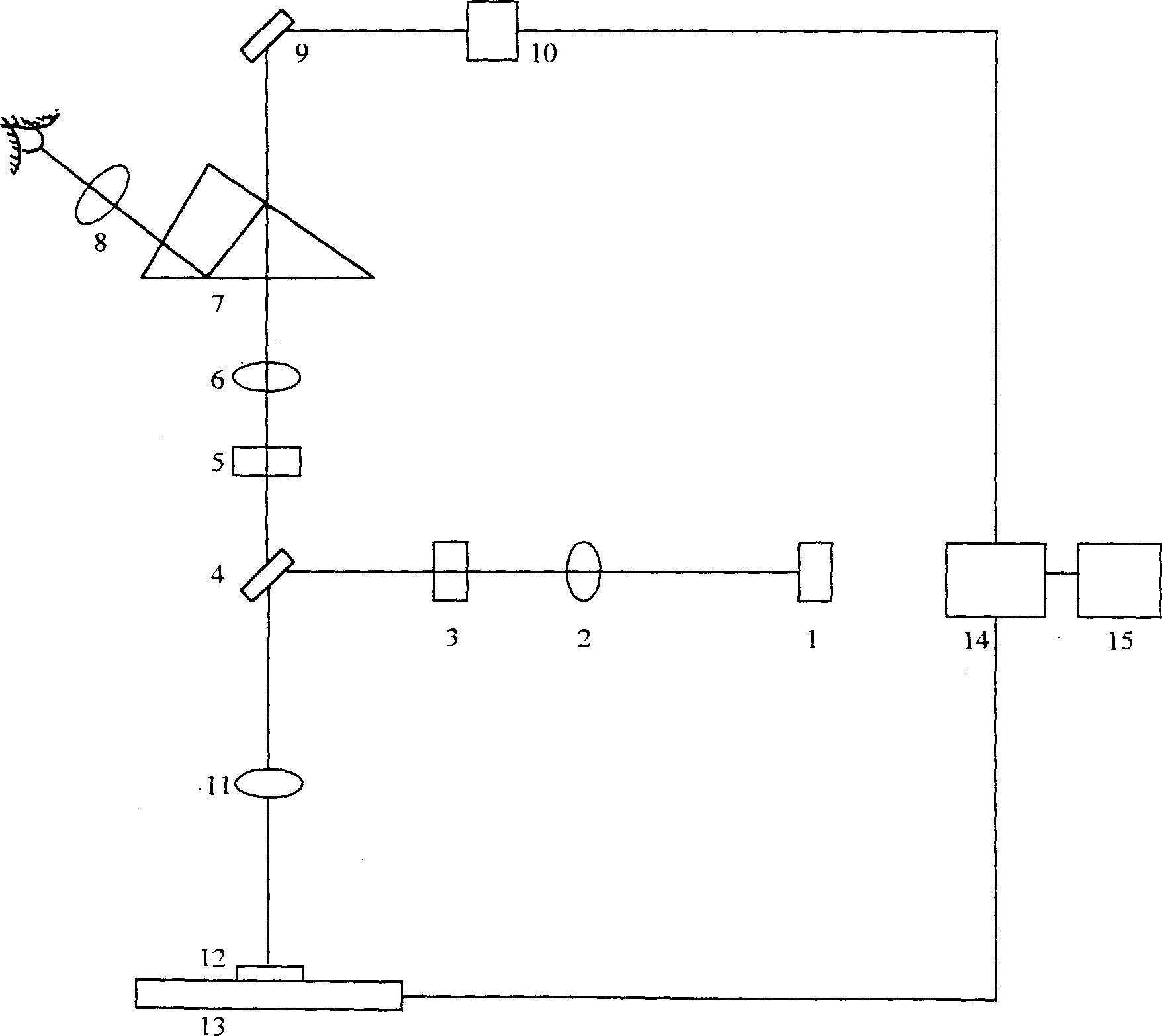

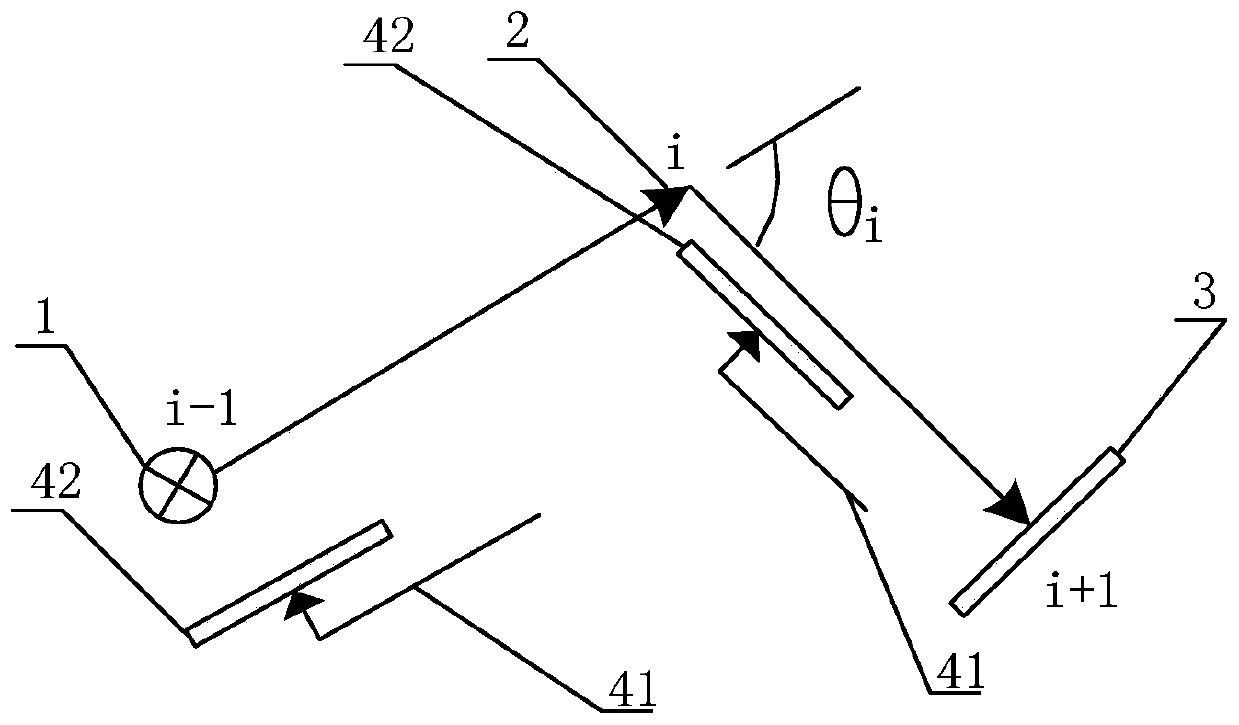

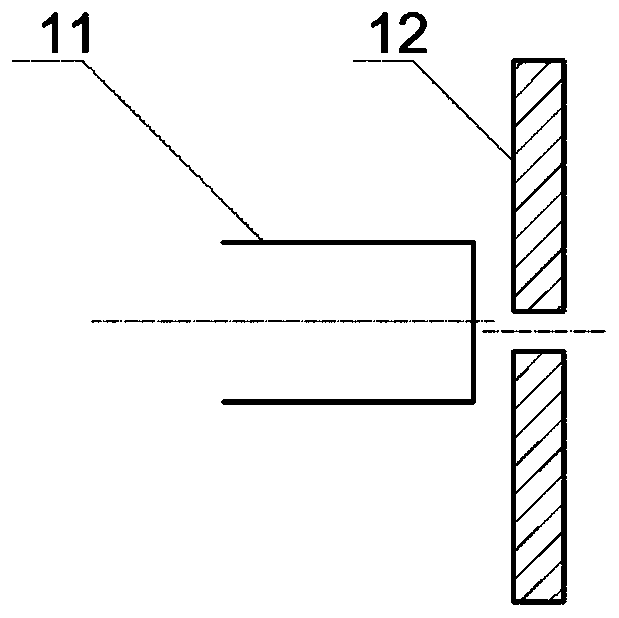

Semi-wave voltage test method and device for Y-waveguide modulator

InactiveCN1432793AAccurate measurementAccurately determineTurn-sensitive devicesWave shapeStep height

Y-waveguide to be measured is connected into Sagnac interferometer light path to form complete Sagnac interferometer. Digital stepped wave with period of 4tau, equal step height and step width of tauis applied to the modulation electrode of Y waveguide, the detector output waveform is measured via A / D technology and the difference between level V1 of the 0-tau region and the level V2 of the tau-4tau is used as the criterion. The step height is altered from high to lower, the different between V1 and V2 is calculated in computer, and when the difference is zero the step height is recorded. According to the relationship between the step height and the semi-wave voltage, the semi-wave voltage of the Y waveguide may be obtained correctly. The said method is simple and high in precision and is not affected by light power variation, light path loss and various phase errors.

Owner:BEIHANG UNIV

Target detection and defect identification method for stockbridge damper of power transmission line

InactiveCN110634127ADetection speedImprove efficiencyImage enhancementData processing applicationsFeature extractionIdentification device

The invention discloses a target detection and defect identification method for a stockbridge damper of a power transmission line. The method comprises the following steps: acquiring a stockbridge damper picture through an image acquisition device; preprocessing the shockproof hammer picture to obtain a preprocessed picture; constructing a feature extraction module, a feature enhancement module and a pixel-level prediction module; performing connection optimization on the feature extraction module, the feature enhancement module and the pixel-level prediction module, and establishing a training model; and inputting the pre-processed picture into a training model for testing, thereby realizing target detection and identification of the shockproof hammer in the pre-processed picture. The invention also provides a target detection and defect identification device for the shockproof hammer of the power transmission line. According to the invention, the detection speed of a high-resolutionpicture is greatly improved; calculation is reduced to a certain extent, rapid and accurate shockproof hammer target detection and defect identification are realized, and the efficiency of electric power inspection work is improved.

Owner:ANHUI NANRUI JIYUAN POWER GRID TECH CO LTD +2

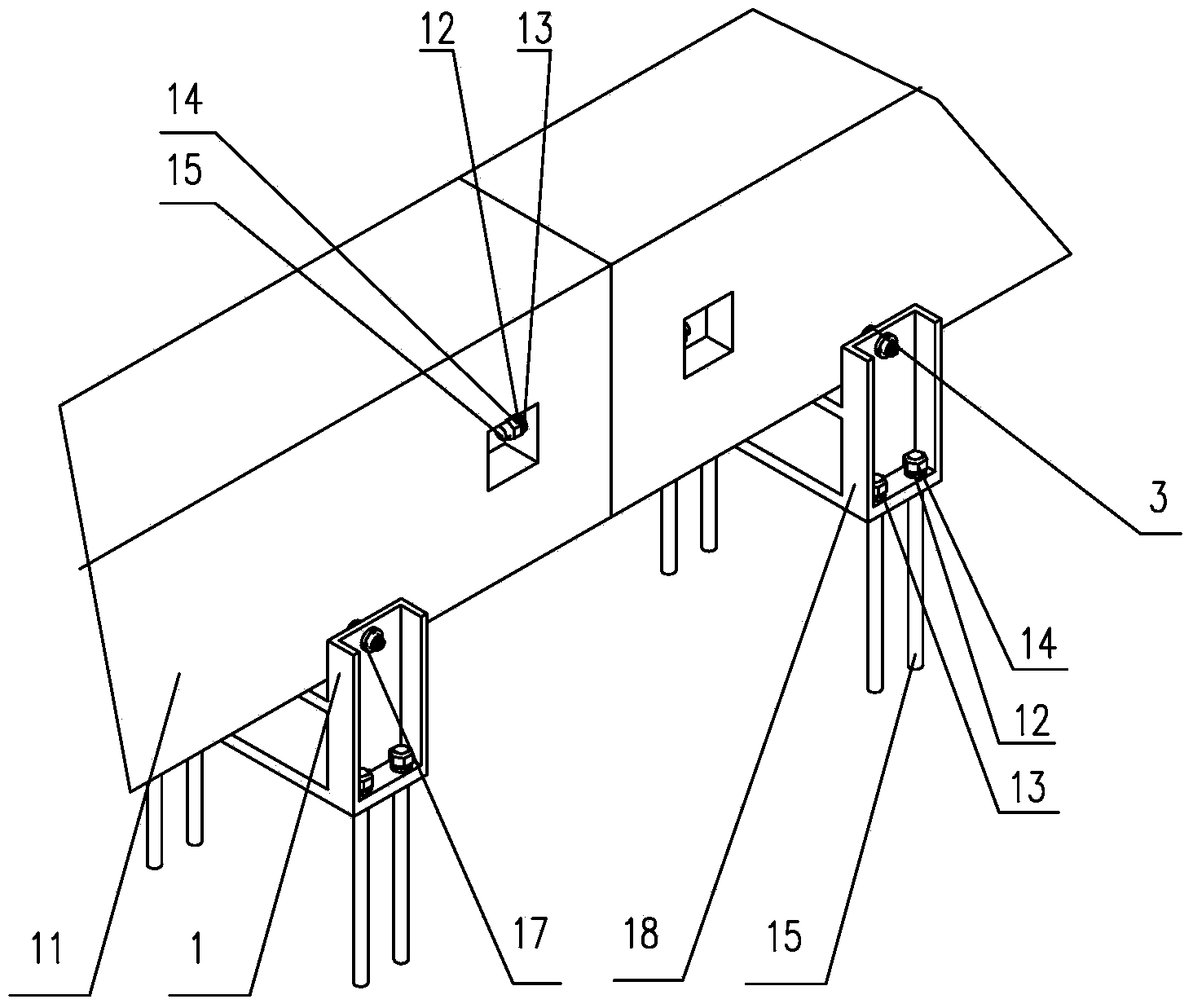

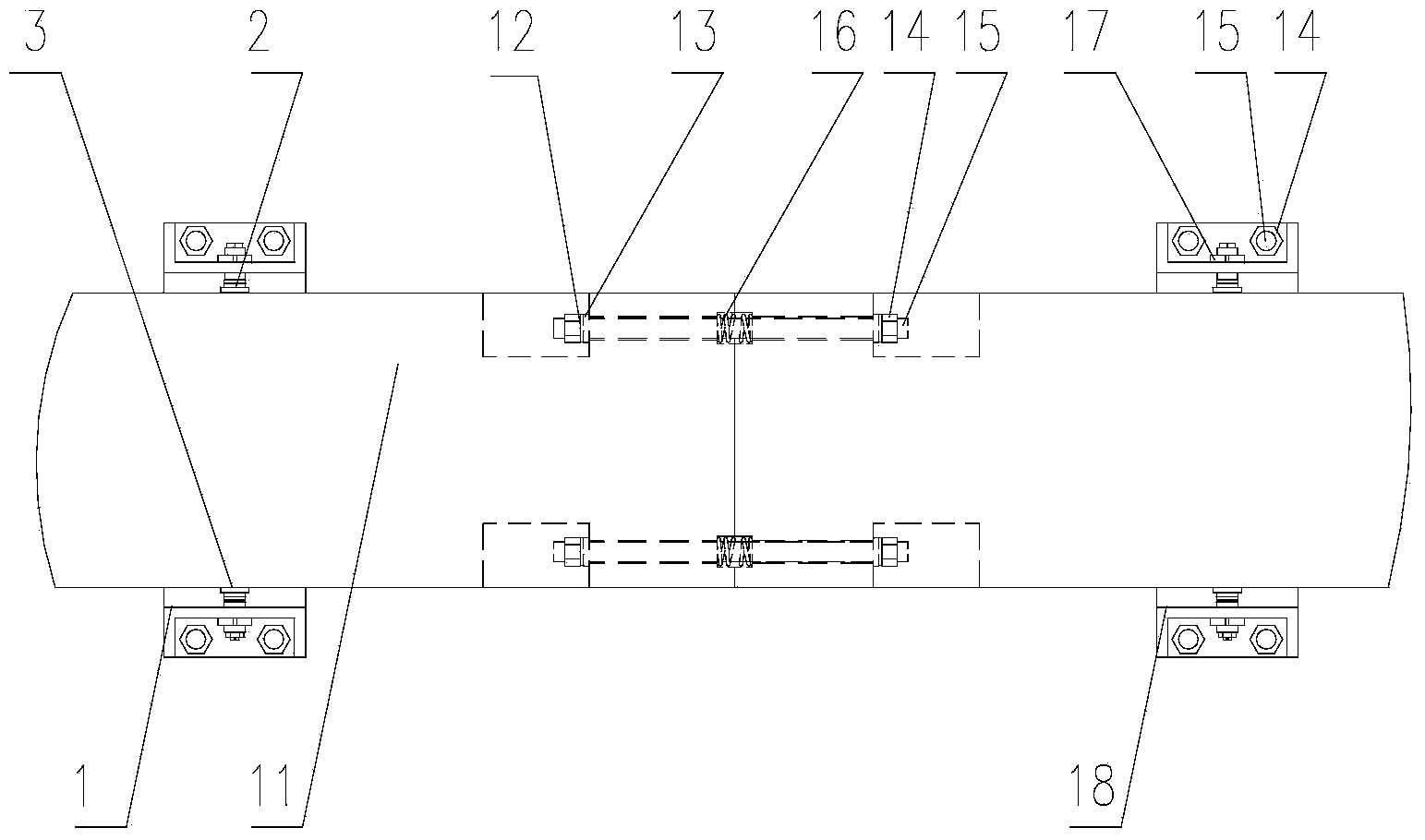

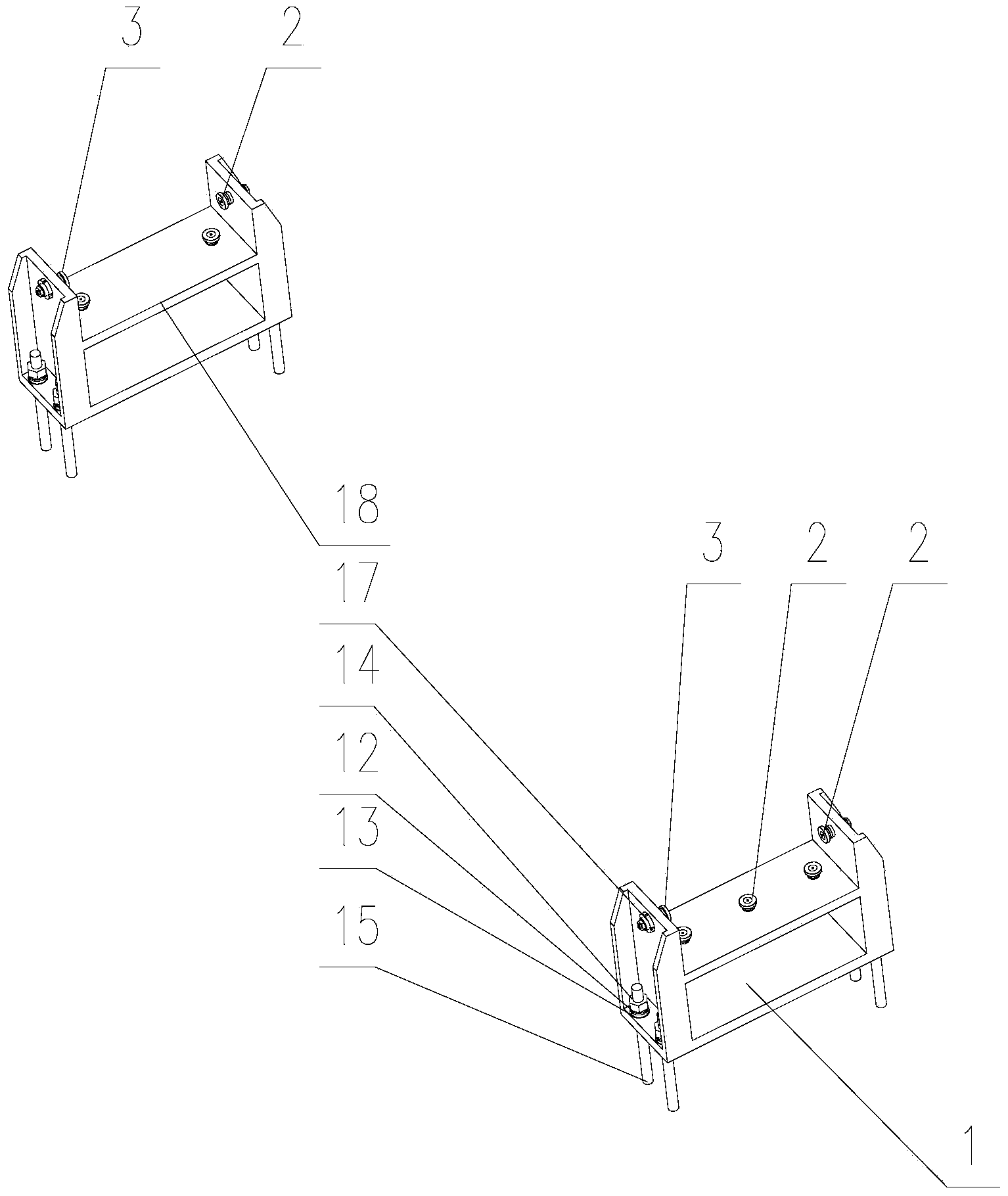

Ultra-long guide rail for three-coordinate measuring machine

InactiveCN103528553AHigh flatness precisionImprove straightnessMeasurement devicesAir bearingHigh intensity

The invention discloses an ultra-long guide rail for a three-coordinate measuring machine. The ultra-long guide rail comprises branch guide rails and front and rear bases for the branch guide rails, wherein four bolt holes for arranging full-thread screws are formed in a lower bottom plate of each of the front and rear bases, and threaded holes are formed in vertical plates and upper bottom plates of the front and rear bases; an elastic adjusting bolt is arranged in one threaded hole of each vertical plate, and rigid adjusting bolts are arranged in the other threaded holes of each vertical plate; a square hole is formed in each of the two ends of each of main and auxiliary lateral surfaces of each branch guide rail, and a pair of stepped holes communicated with the corresponding square holes is formed in each of the front and rear end faces of each branch guide rail; springs are arranged in the stepped holes of the spliced end faces; the full-thread screws penetrate through the springs in the stepped holes; the two ends of the full-thread screws are positioned in the corresponding square holes respectively, and are locked by nuts. The ultra-long guide rail is high in planeness accuracy, straightness and splicing seam bonding accuracy, strong in splicing seam bonding strength, small in bonding seam thickness, simple in structure, easy to assemble, free of maintenance and low in cost, influence on accuracy when air bearings pass through bonding seams is avoided, and the accuracy, comprising the planeness and the straightness, of the guide rail is kept unchanged when temperature is changed.

Owner:浙江时代计量科技有限公司

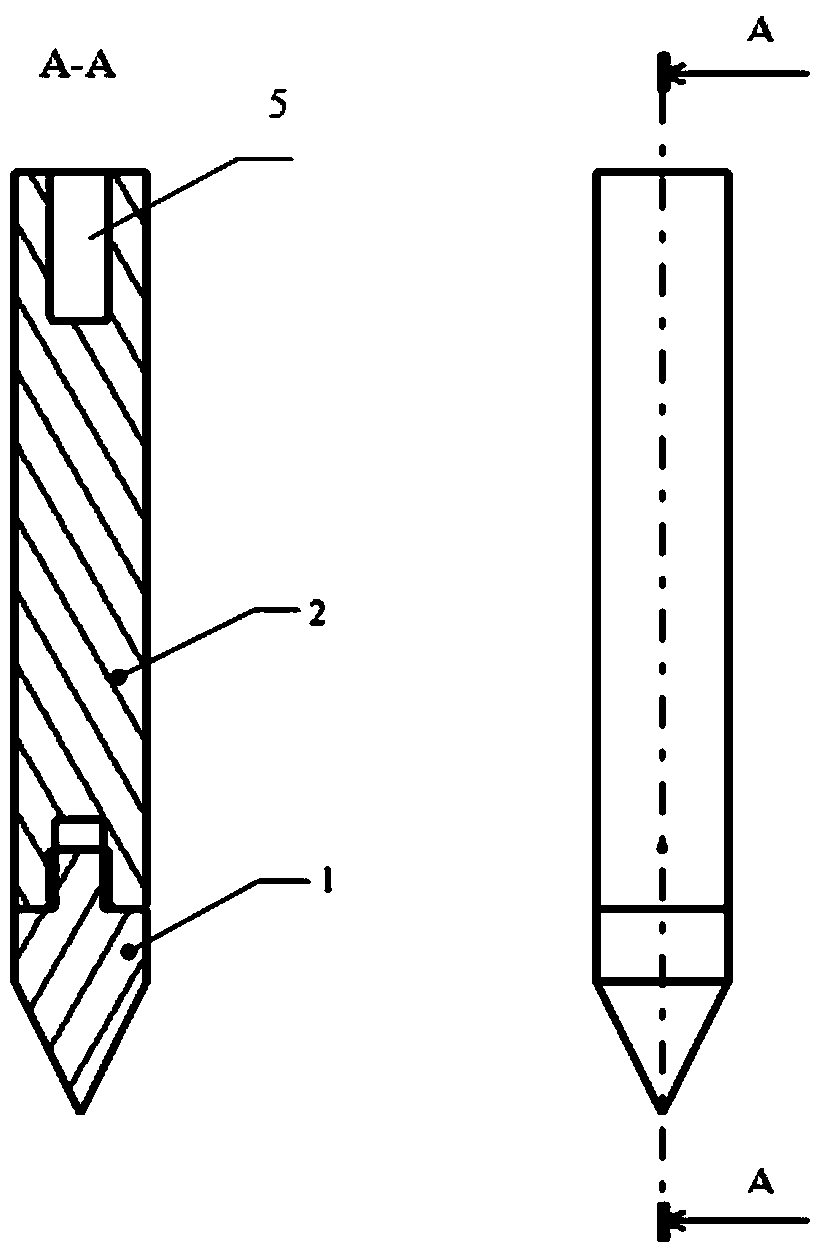

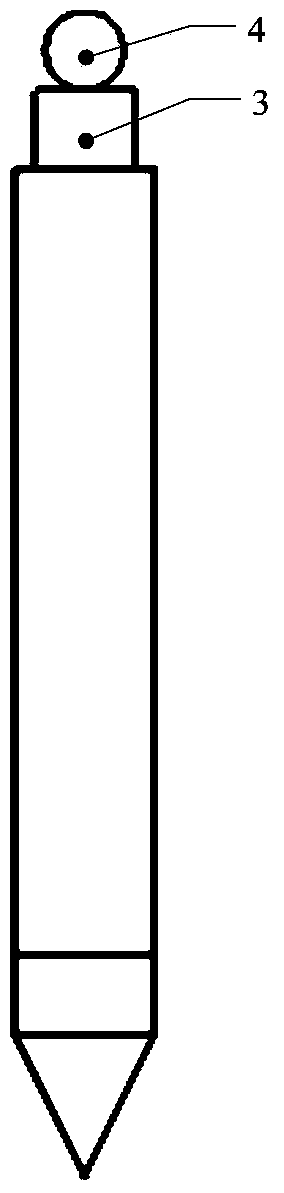

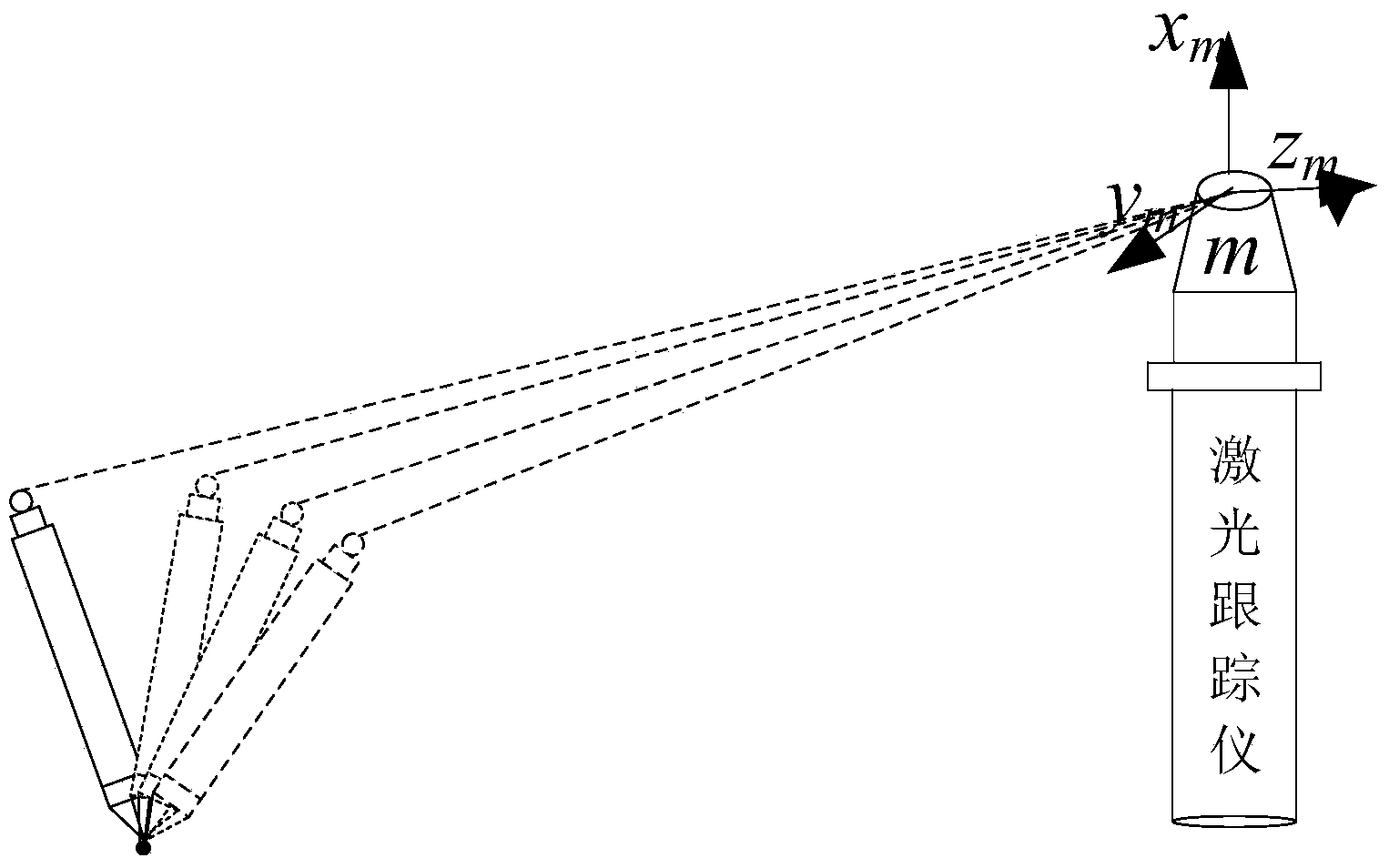

Handheld portable measuring tool based on laser tracker and measuring method thereof

The invention discloses a handheld portable measuring tool based on a laser tracker and a measuring method of the handheld portable measuring tool. The measuring tool is a measuring pen which is composed of a conical pen head and a pen rod provided with a target ball base positioning hole. After a target ball base is installed on the pen rod, the pen point of the pen head aligns to and makes contact with a measuring point, a target ball is held by hand to be led to the target ball base, the measuring pen rod is slowly rotated and is kept stable at four positions, the laser tracker measures the coordinate values at the four positions of the target ball, and then the position coordinates of the measuring point of the pen head can be calculated. The handheld portable measuring tool based on the laser tracker and the measuring method of the handheld portable measuring tool have the advantages that no target ball base positioning holes need to be machined in the measuring point, and only the condition that the micro plane where the measuring point is located enables the pen point to be kept stable and aligning when the measuring pen rotates needs to be ensured; the measuring pen does not need to be demarcated, and measuring pen manufacturing errors and form and location tolerances have no influence on the accuracy of a measuring result; the structure is simple, using is convenient, the algorithm can be programmed into the control program of the laser tracker, and the application range is wide.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

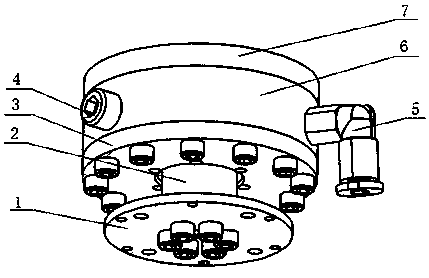

Robot collision protection device

The invention discloses a robot collision protection device. A gas input interface is formed in a shell, and an opening is formed in the lower side wall of the shell; a lower cover is movably connected with the shell, the lower cover comprises a base arranged in the shell, the base abuts against the lower side wall of the shell, the base covers and seals the opening, and the base and the shell areassembled to form a sealing cavity used for containing gas; an elastic assembly is arranged in the shell and abuts against the lower cover downwards. When the lower cover moves upwards under the action of external force, an exhaust gap is formed between the base and the lower side wall of the shell, and the exhaust gap and the opening form an air leakage channel capable of exhausting air in the sealing cavity outwards. An executing mechanism connecting assembly is arranged on the lower cover, and a robot tail end connecting assembly is arranged on the shell. According to the robot collision protection device, when collision or overload occurs, automatic load unloading is achieved, and a robot tail end executing mechanism and equipment are protected.

Owner:CHONGQING HONGJIANG MACHINERY

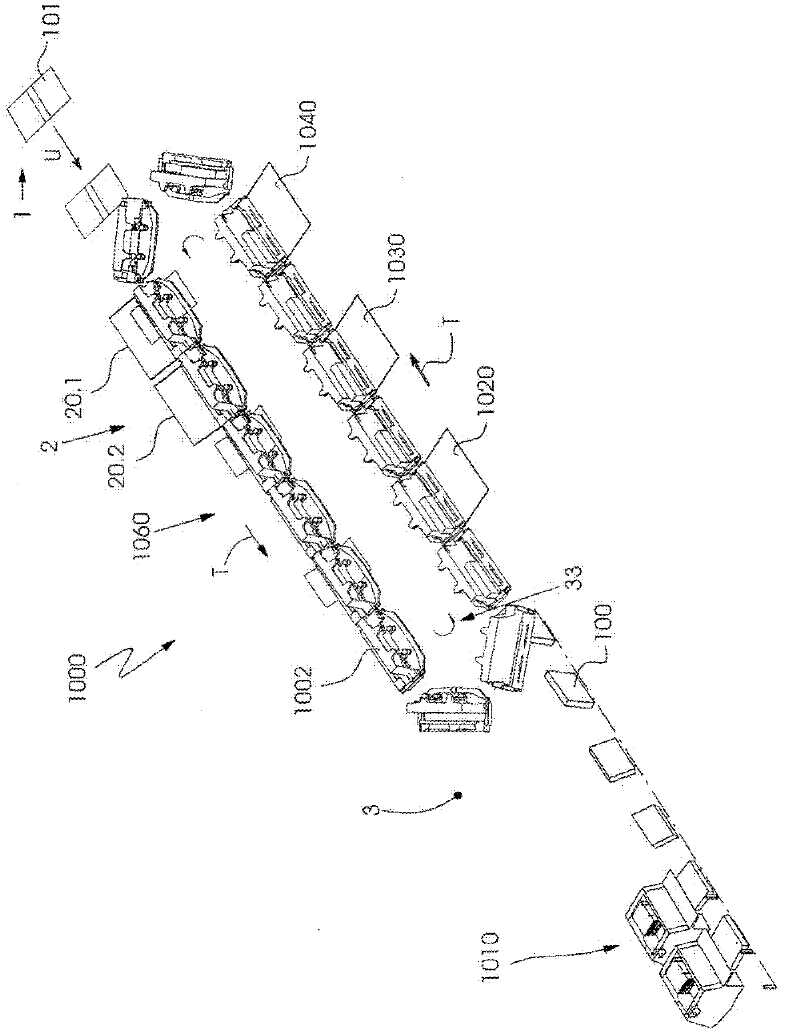

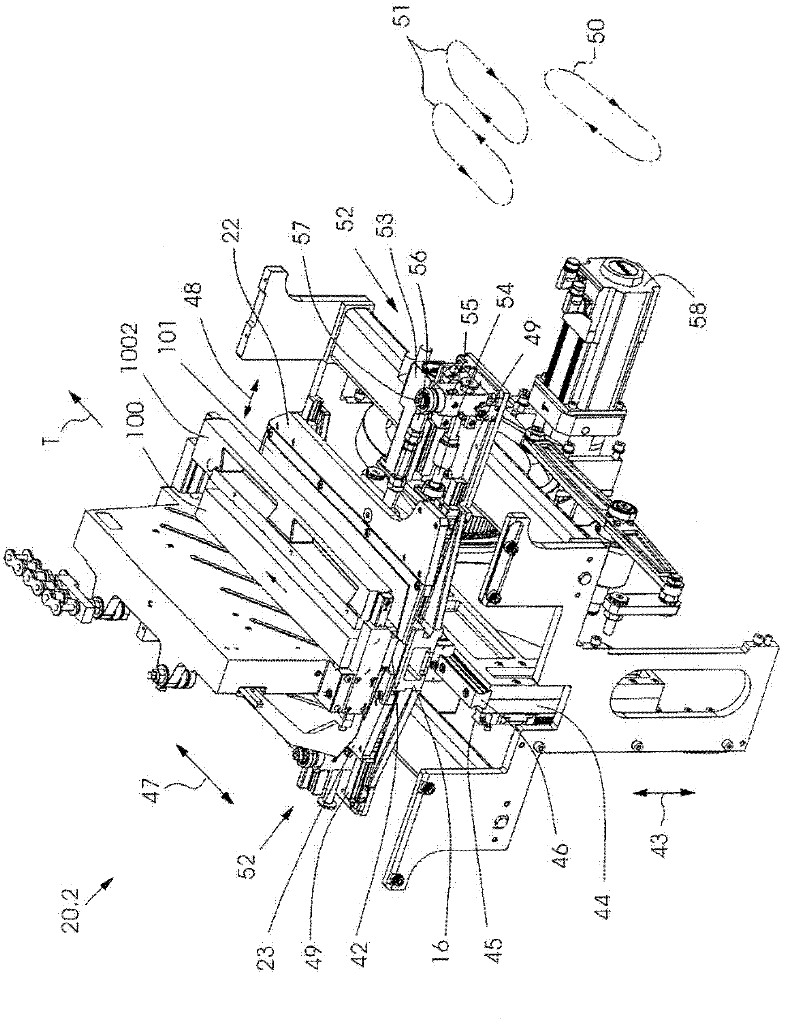

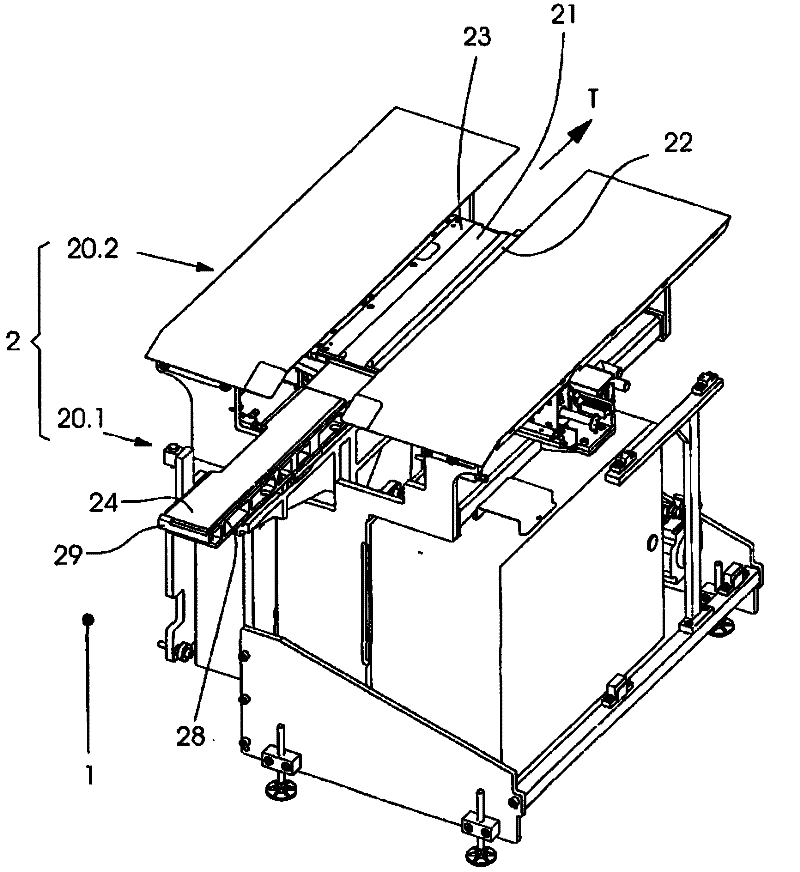

Device for laying a cover

ActiveCN102529484APromote reproductionEasy to adjustRegistering devicesCasing-inTransport systemMechanical engineering

The invention provides a device for moving a cover (101) provided by the transport system (35) of a cover feeding station (1) along the transport direction (T) and laying and aligning the cover on a printing core (100) with an adhesive layer. The device comprises a pressing bench (28) capable of moving along the vertical and horizontal directions. The pressing bench comprises a pressing surface (24) used for substantially horizontally laying and pressing a cover. The transport systems (33, 35) are driven by individual drives. The pressing bench (28) has a driver (29) protruding from the pressing surface (24).

Owner:MULLER MARTINI HLDG

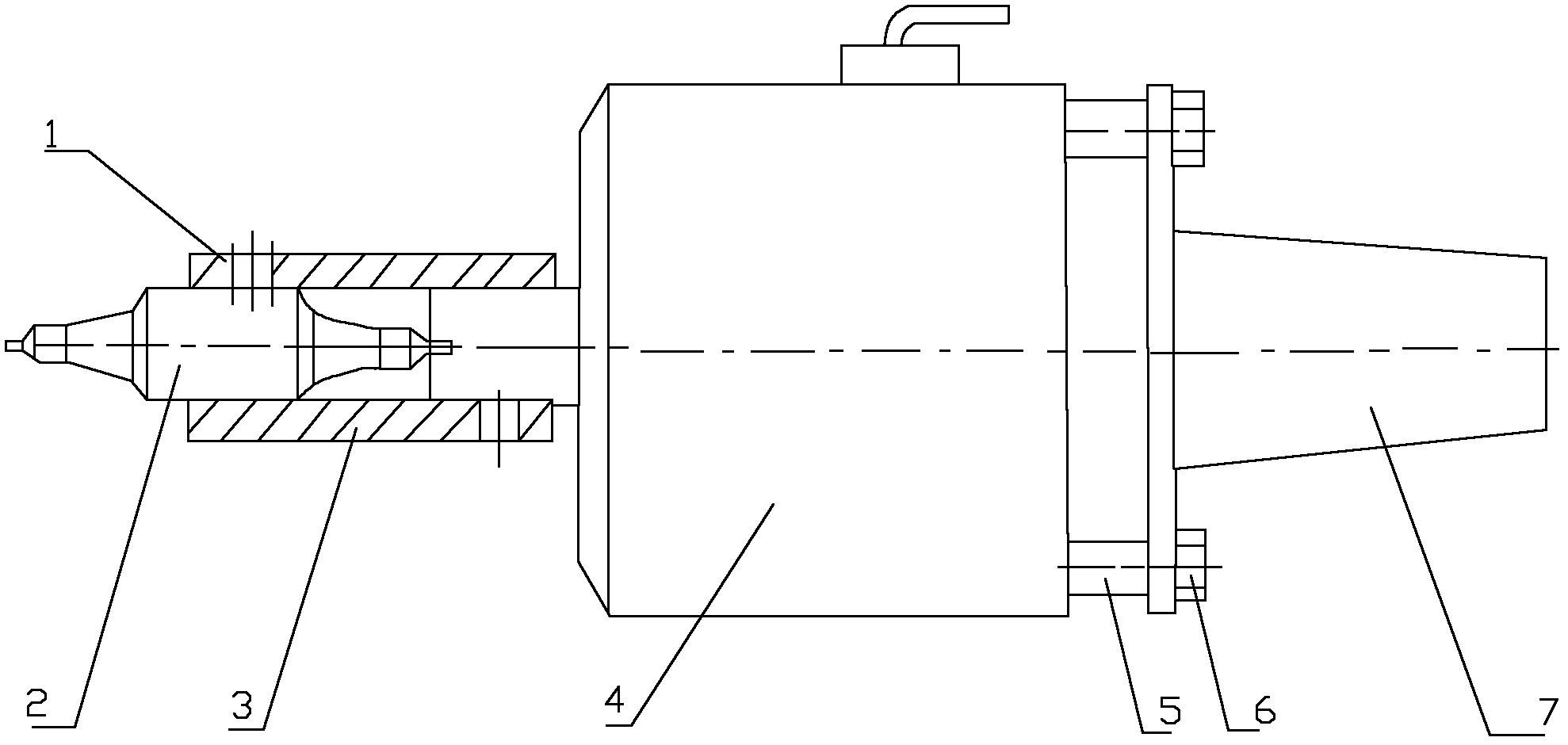

Apparatus for locking accurate main shaft

The invention provides a precise spindle locking device and relates to a locking device. The locking device consists of a fixed board, a flange, braking blocks, dowel bars and a locking oil cylinder, wherein the braking blocks and the dowel bars are arranged at two sides of the flange and are bilaterally symmetric. The flange is fixed on a spindle. The fixed board is fixed on a spindle box. The dowel bars are fixed on the fixed board. The braking blocks are fixed on the inner sides of the dowel bars. The locking oil cylinder is fixed between the left and right dowel bars. Stop pins are arranged on the outer sides of the dowel bars. The dowel bars can rotate by taking only rotating shafts as centers. Braking blocks are fixed on the dowel bars through rotating pins. Based on principles of self-centering and lever force amplification, the precise spindle locking device avoids any influence on the precision of the spindle when the spindle is locked and absolutely reliable locking is achieved, thereby ensuring the precision of processed parts, the precision of the spindle and the service life of the spindle.

Owner:GUANGZHOU CITY AGILE MFG

PCB bell mouth manufacturing method

InactiveCN107396540AHigh quality and reliabilitySave manpower/material resourcesPrinted circuit aspectsPrinted circuit manufacturePunchingMachine parts

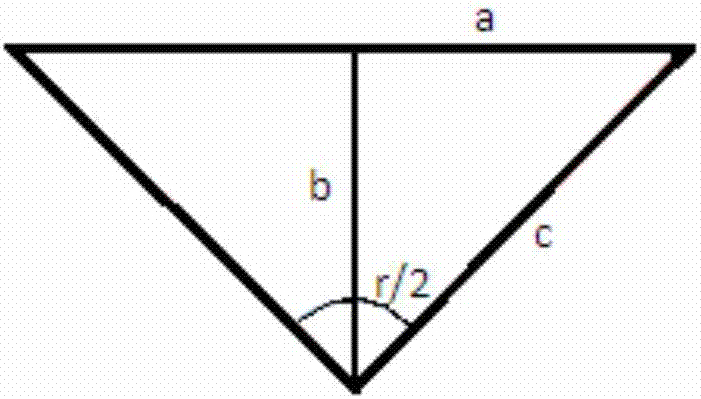

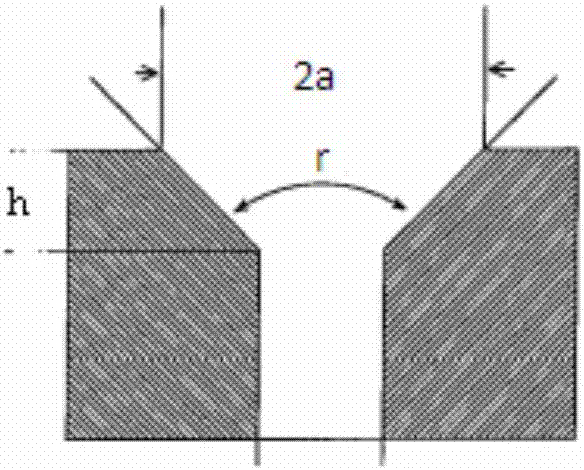

A PCB bell mouth manufacturing method comprises the following steps: 1, selecting a taper drill bit according to the bell mouth sizes; 2, calculating a drilling depth according to the client required bell mouth orifices bore diameter, and writing the result <b=a / tg(r / 2)> into a bell mouth boring program; 3, working in order according to a routine boring flow: a, mounting a joist plate; b, planting pins; c, loading a backing plate; d, loading a drilled plate; e, covering an aluminium sheet and pasting a gummed paper; f, starting a machine part mushroom head to press the aluminium sheet; g, covering a cold punching plate and using a gummed paper to firmly paste on same; 4, using an universal meter to confirm the aluminium sheet is connected with a drilling crew table top, and ensuring the unique coupling conduction portion between the aluminium sheet and the drilling crew table top is the mushroom head; 5, boring. The method calculates the drilling depth according to the tapper drilling bit angle and inputs the program, and the drilling crew can automatically make the bell mouth; the method is high in efficiency, and can make the precise bell mouths.

Owner:AOSHIKANG TECH CO LTD

Blockchain-based federated modeling method, device, equipment and storage medium

ActiveCN111552986BAccuracy has no effectAccuracy impactDigital data protectionNeural architecturesSimulationPrivacy protection

The present invention discloses a blockchain-based federated modeling method, device, device, and storage medium. The method includes: when the number of training clients detected reaches a preset number, the training initiator corresponds to The client information releases configuration information to each training client; the training initiator uploads the model to be trained to the main chain; the training initiator determines the target model based on the aggregation gradient and the model to be trained. The invention realizes the modeling of federated learning through the block chain. Under the premise of protecting the privacy of federated learning data, it has no impact on the accuracy of federated learning, improves the training effect and model accuracy of federated learning, and does not need to modify the gradient in transmission. Modification of model parameters such as gradients achieves a balance between privacy protection of model parameters such as gradients and model convergence or model accuracy; it can completely prevent information leakage and improve the security of data samples in federated learning.

Owner:PENG CHENG LAB +1

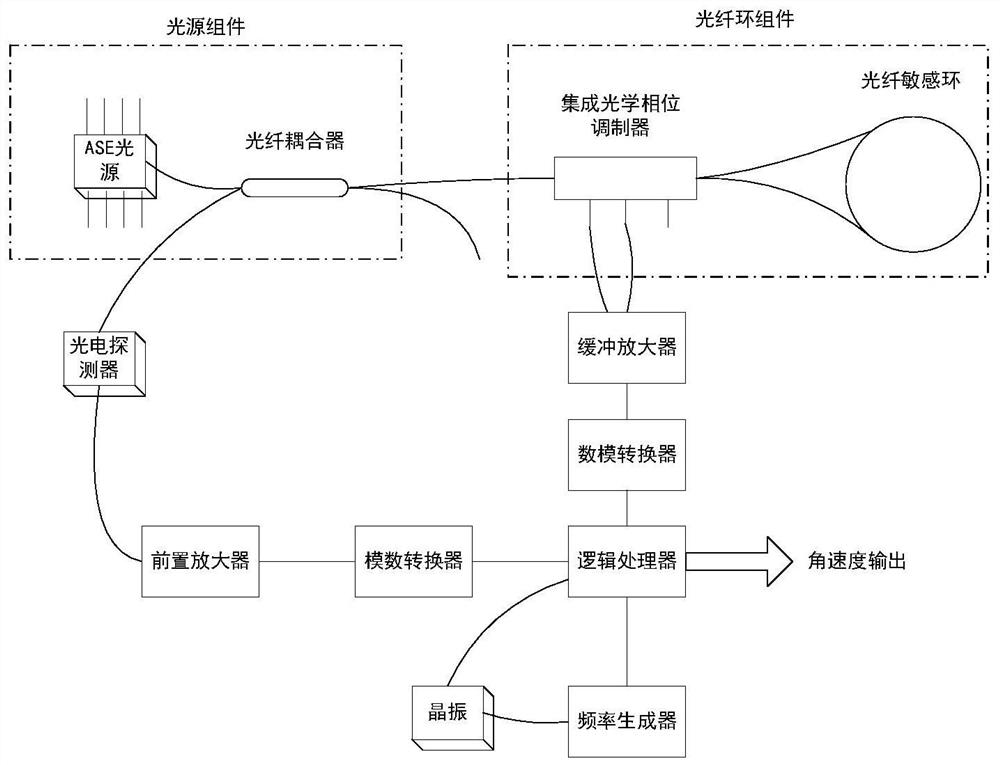

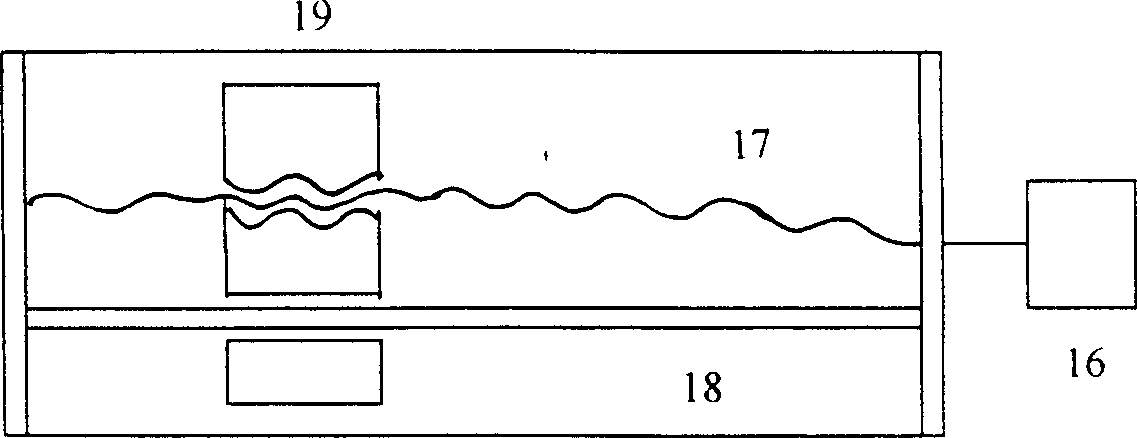

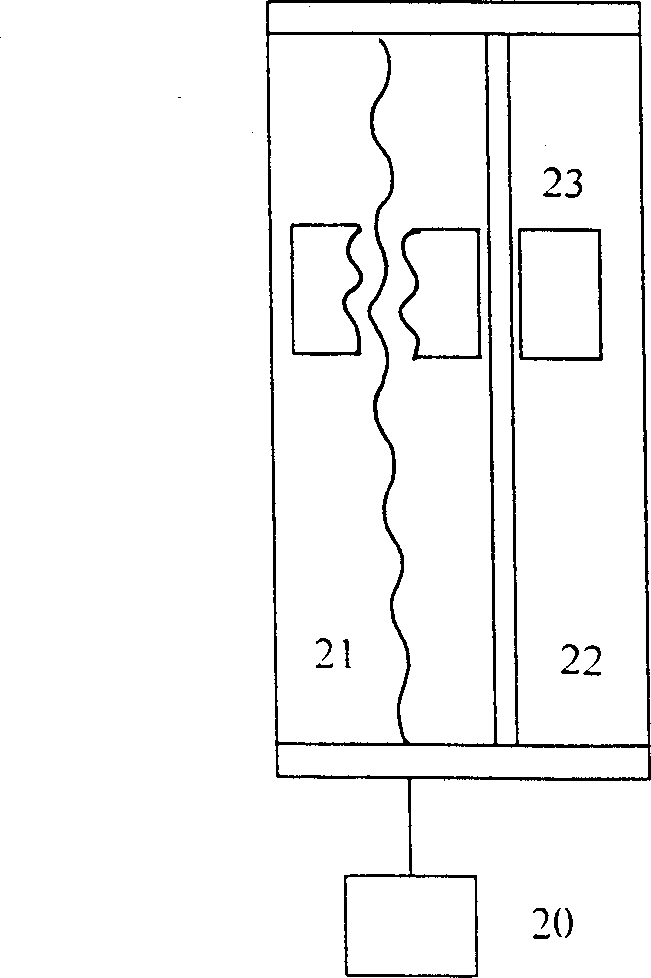

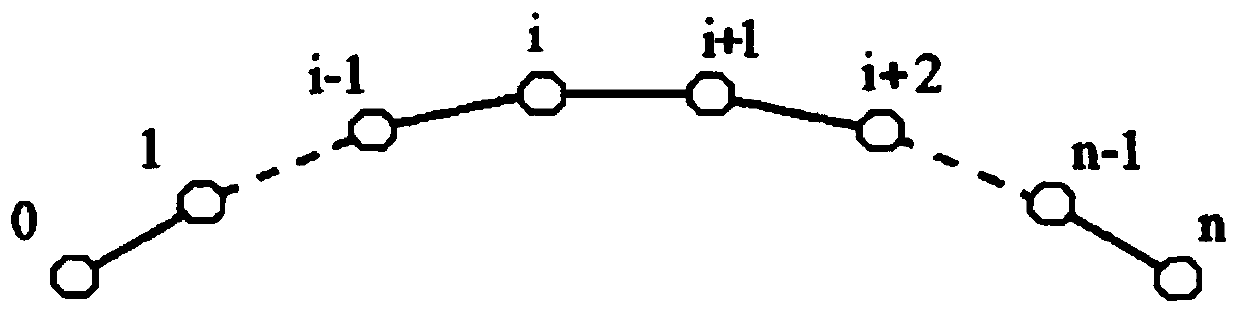

On-line tracking method and system for eigenfrequency of fiber-optic gyroscope

ActiveCN112697125AImplement automatic trackingAccuracy has no effectSagnac effect gyrometersGyroscopeSoftware engineering

The invention discloses an on-line tracking method and system for eigenfrequency of a fiber-optic gyroscope. The fiber-optic gyroscope comprises an ASE light source, an optical fiber coupler, an integrated optical phase modulator and a light sensitive ring which are connected in sequence, the feedback end of the optical fiber coupler sequentially passes through the photoelectric detector, the pre-amplifier and the analog-to-digital converter and then is input to the signal receiving end of the logic processor, and the control end of the integrated optical phase modulator sequentially passes through the buffer amplifier and the digital-to-analog converter and then is connected to the signal sending end of the logic processor. The method comprises the following steps: constructing a modulation signal obtained by superposing a four-state square wave and a sawtooth wave, transmitting the modulation signal through a closed-loop control loop of the fiber-optic gyroscope to obtain a to-be-demodulated signal, demodulating an error between a modulation frequency and an actual frequency of the fiber-optic gyroscope, and dynamically adjusting a modulation frequency source clock of the fiber-optic gyroscope. Therefore, automatic tracking of the eigenfrequency of the fiber-optic gyroscope is realized, an angular velocity closed loop and a half-wave voltage closed loop are not influenced, and the precision of an angular velocity channel of the fiber-optic gyroscope is not influenced.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

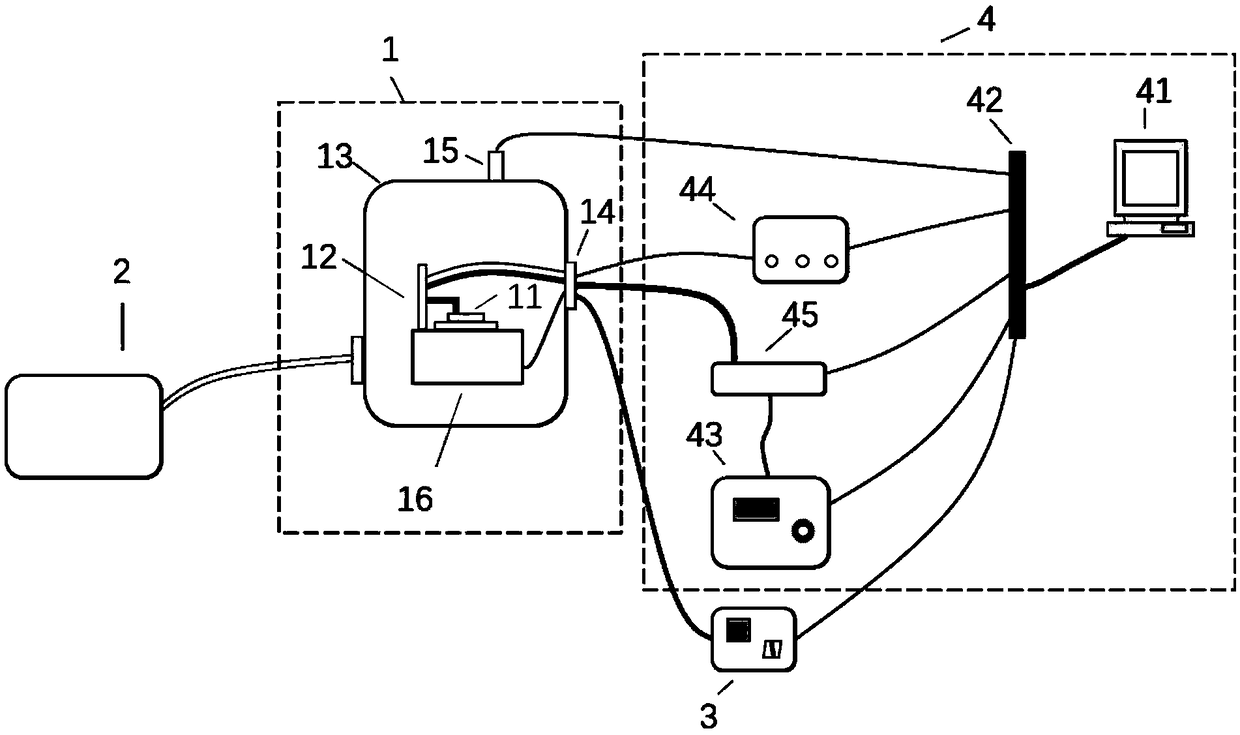

Gene chip tester

A gene chip tester is composed of fluorescent exciting unit, probing unit, scan unit, A / D converter and computer for processing the signals from probing unit and A / D converter, and controlling scan unit to move in X and Y directions.

Owner:北京清大德人显微数字技术有限公司

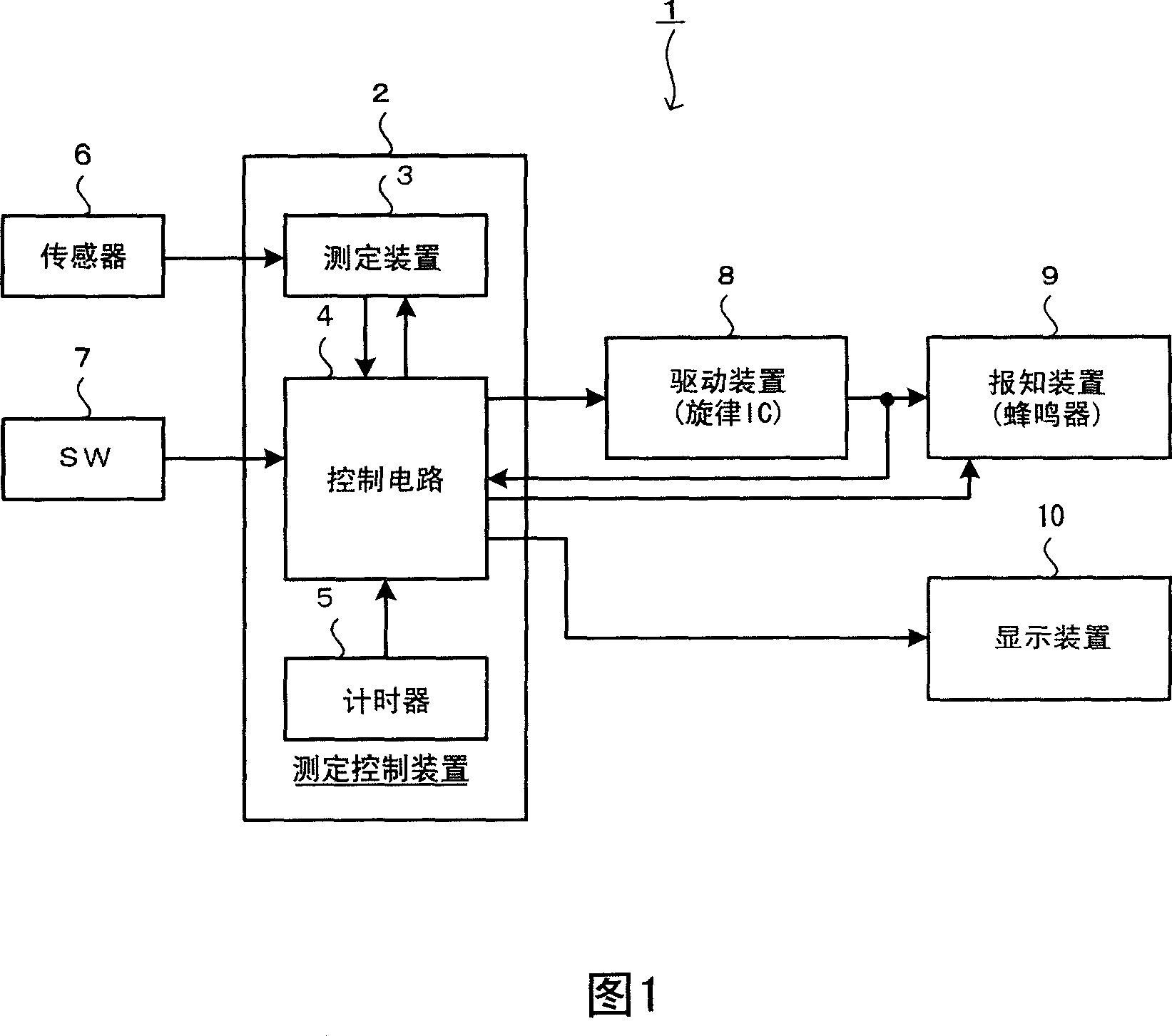

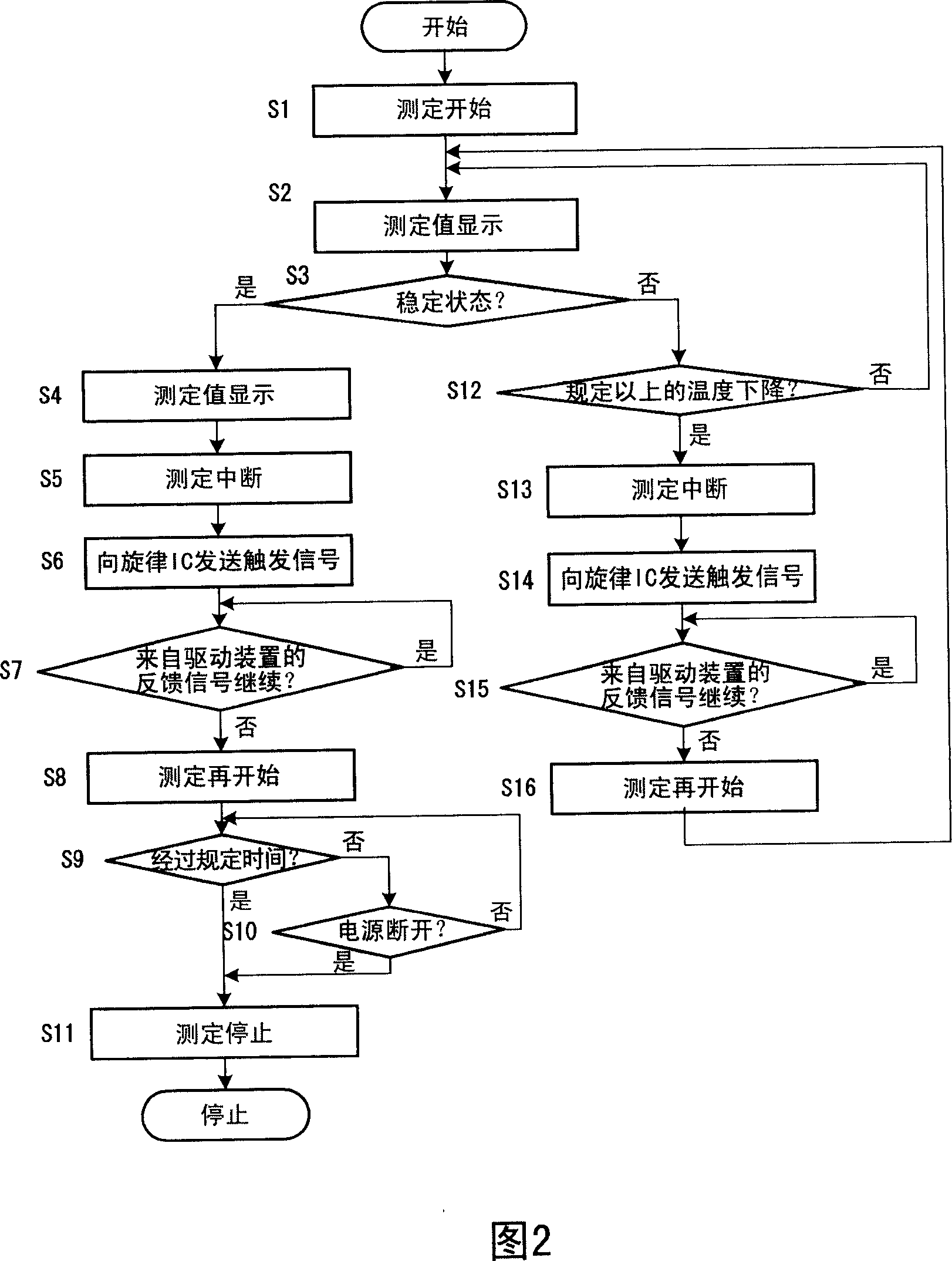

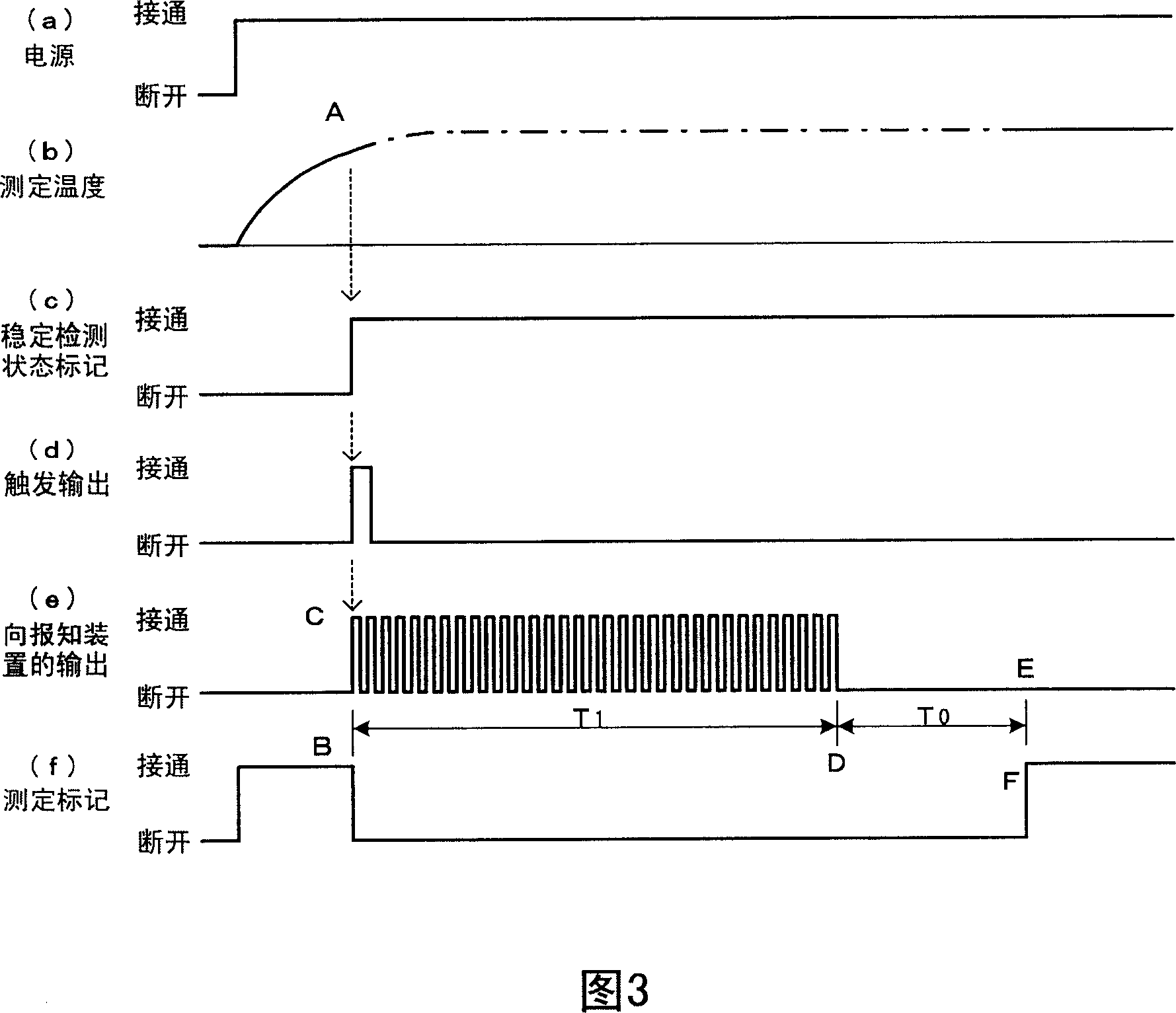

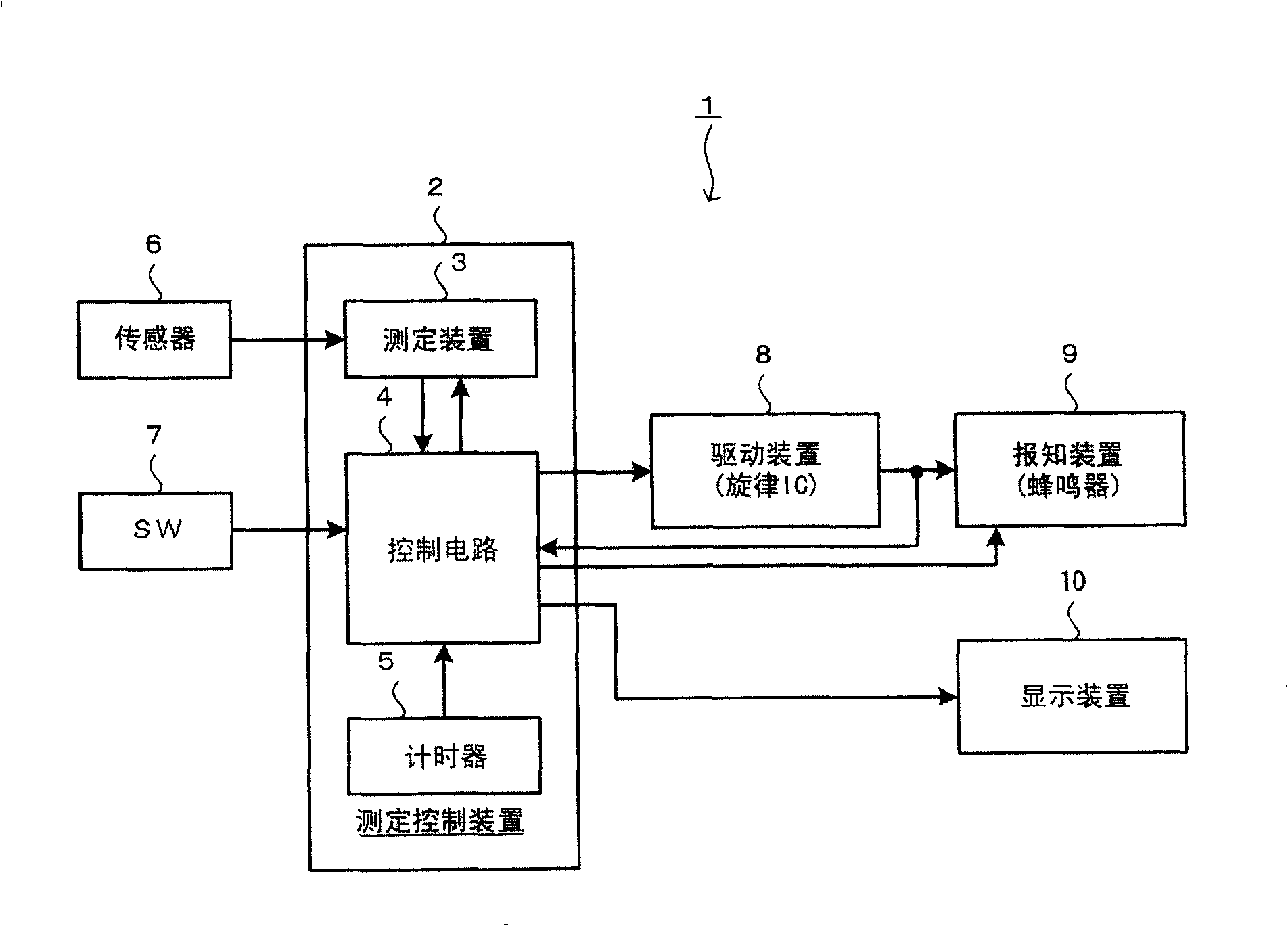

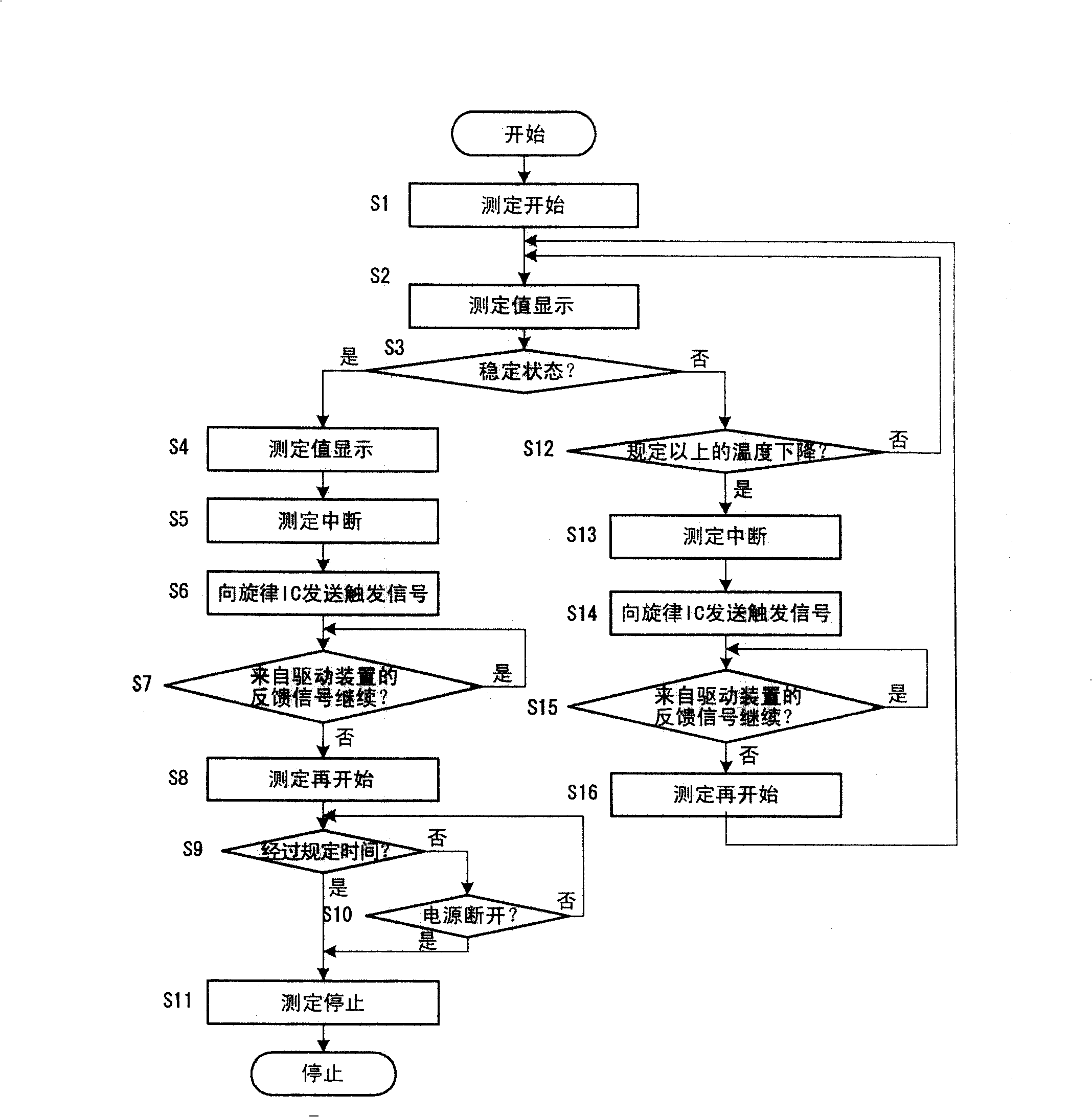

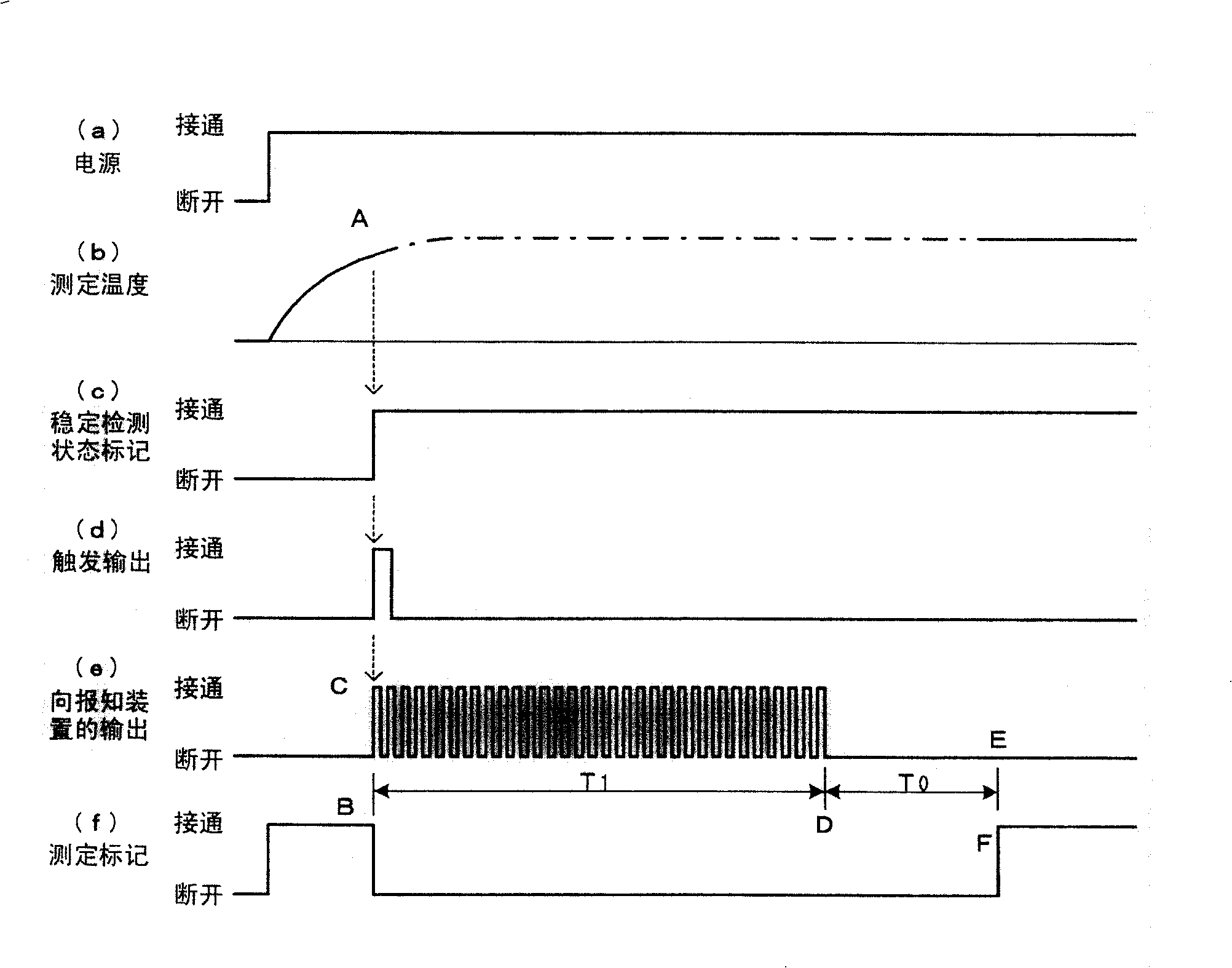

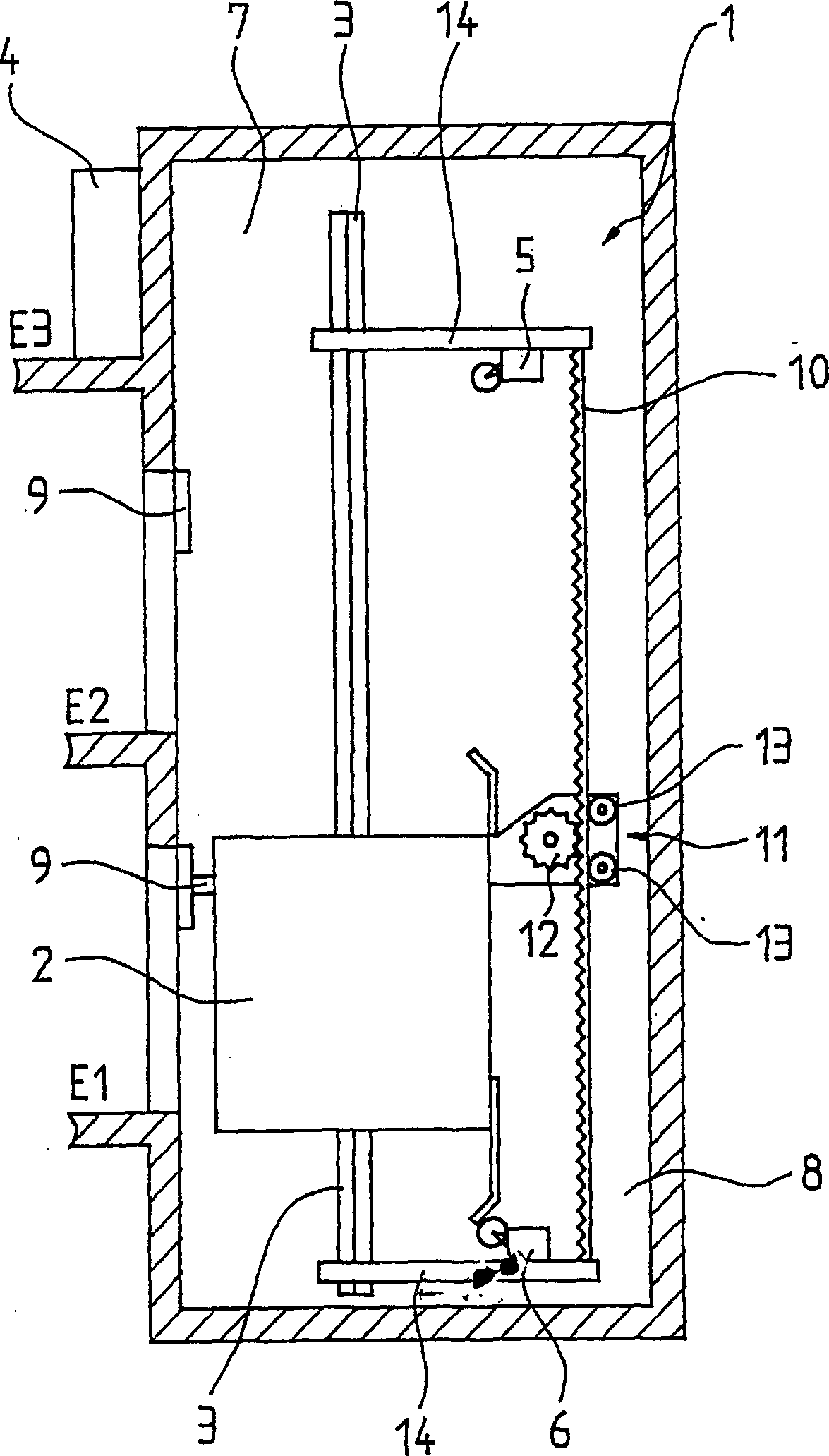

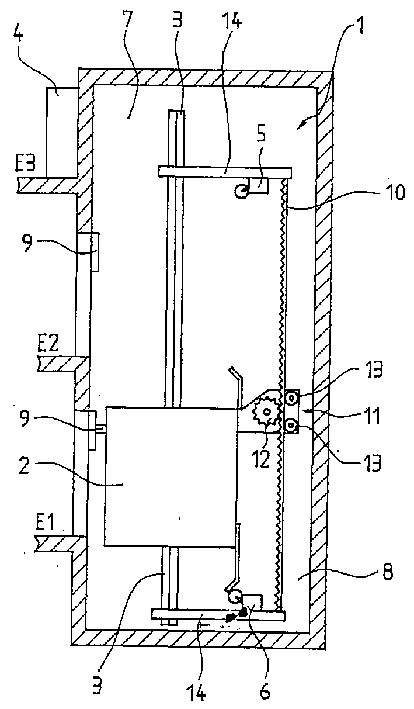

Electronic clinical thermometer

InactiveCN1926418APrevents drop in measurement accuracyAccuracy has no effectThermometers using electric/magnetic elementsBody temperature measurementMeasurement deviceControl circuit

An electronic clinical thermometer includes a control circuit (4) which controls operation timing according to the operations of a measurement device (3) and a notification device (9) so that the measurement operation and the notification operation will not be performed simultaneously, thereby preventing lowering of the measurement accuracy due to battery voltage lowering. The electronic clinical thermometer (1) includes the measurement device (3) for measuring a body temperature, a drive device (8) for recording the notification data, the notification device (9) for performing notification by a drive signal formed according to the notification data, and the control circuit (4) for controlling the measurement operation and the notification operation. The control circuit (4) performs control so that the operation timing of the measurement device (3) is shifted from the operation timing of the notification device (9) according to their operation states so as to prevent simultaneous operations of the measurement and notification. Thus, in the electronic clinical thermometer performing notification operation, it is possible to prevent simultaneous execution of the measurement operation and notification operation, which in turn prevents measurement accuracy lowering due to battery voltage lowering.

Owner:CITIZEN WATCH CO LTD

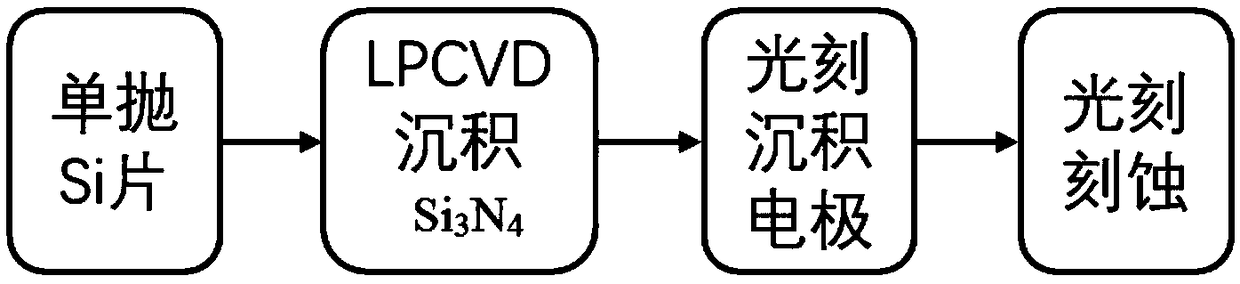

Device for measuring thermal conductivity of film with steady-state method

PendingCN109444214AThe principle is simpleReduce test errorMaterial heat developmentTransmittanceThermal conductivity

The invention relates to the field of material performance characterization, in particular to a device for measuring thermal conductivity of a film with a steady-state method. The device comprises a sample analysis chamber, a vacuum acquisition system, a temperature control system and a signal monitoring and automatic recording system, wherein a sample is placed on a test chip in the sample analysis chamber, and the sample analysis chamber has a vacuum sealing function; the vacuum acquisition system is connected with the sample analysis chamber to provide a vacuum test environment for the sample; the temperature control system heats, cools or insulates the test chip and provides a variable temperature test environment for the sample; the signal monitoring and automatic recording system isconnected with the temperature control system for automatic temperature setting and recording. In-plane thermal conductivity of a thin film material is accurately measured, and especially when other commercial computers cannot be used for thermal conductivity testing due to too small size or high light transmittance and the like of the sample, thermal conductivity of the sample can be accurately and rapidly obtained by the device.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aqueous transfer membrane demolding agent as well as preparation method and application thereof

ActiveCN110527348AExtended service lifeFast and efficient strippingChemical paints/ink removersSolventSURFACTANT BLEND

The invention relates to an aqueous transfer membrane demolding agent as well as a preparation method and application thereof. The aqueous transfer membrane demolding agent consists of the following components in parts by mass: 10-25% of an inorganic strong base, 10-20% of an organic weak base, 8-20% of a main solvent, 5-20% of a cosolvent, 2-5% of a surfactant, 1-15% of a chelating agent and thebalance of water. The aqueous transfer membrane demolding agent provided by the invention has the properties of rapidness and high efficiency, can be repeatedly used for a long time, has no influenceupon a substrate surface, particularly the precision of a sapphire cover plate, and has good application prospects in the precise processing industry.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

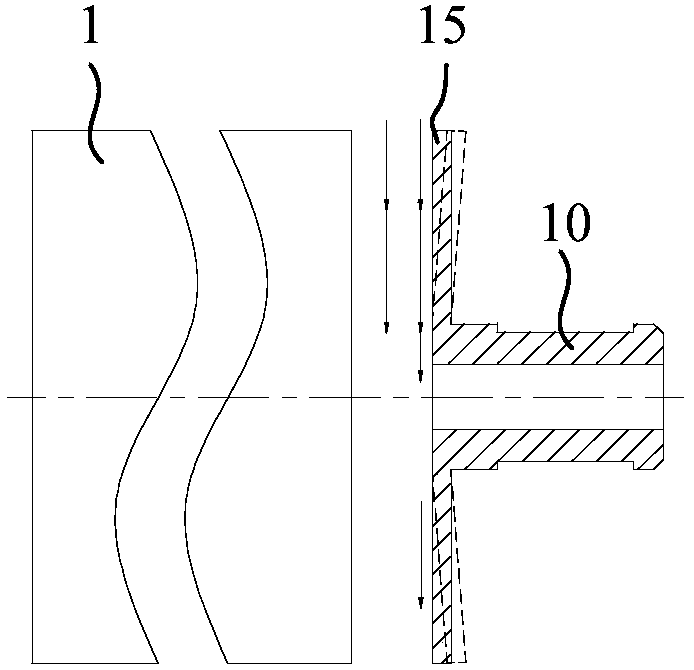

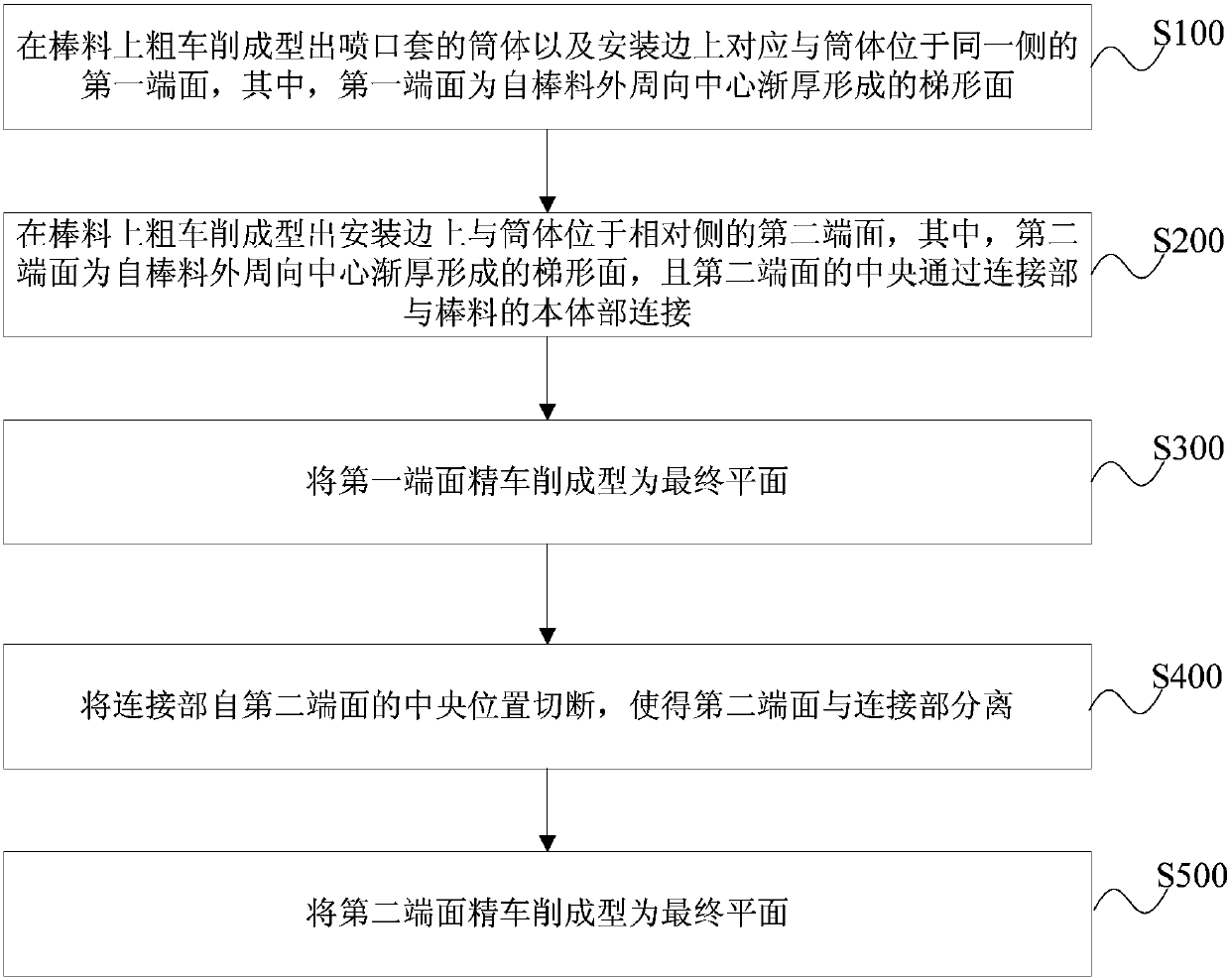

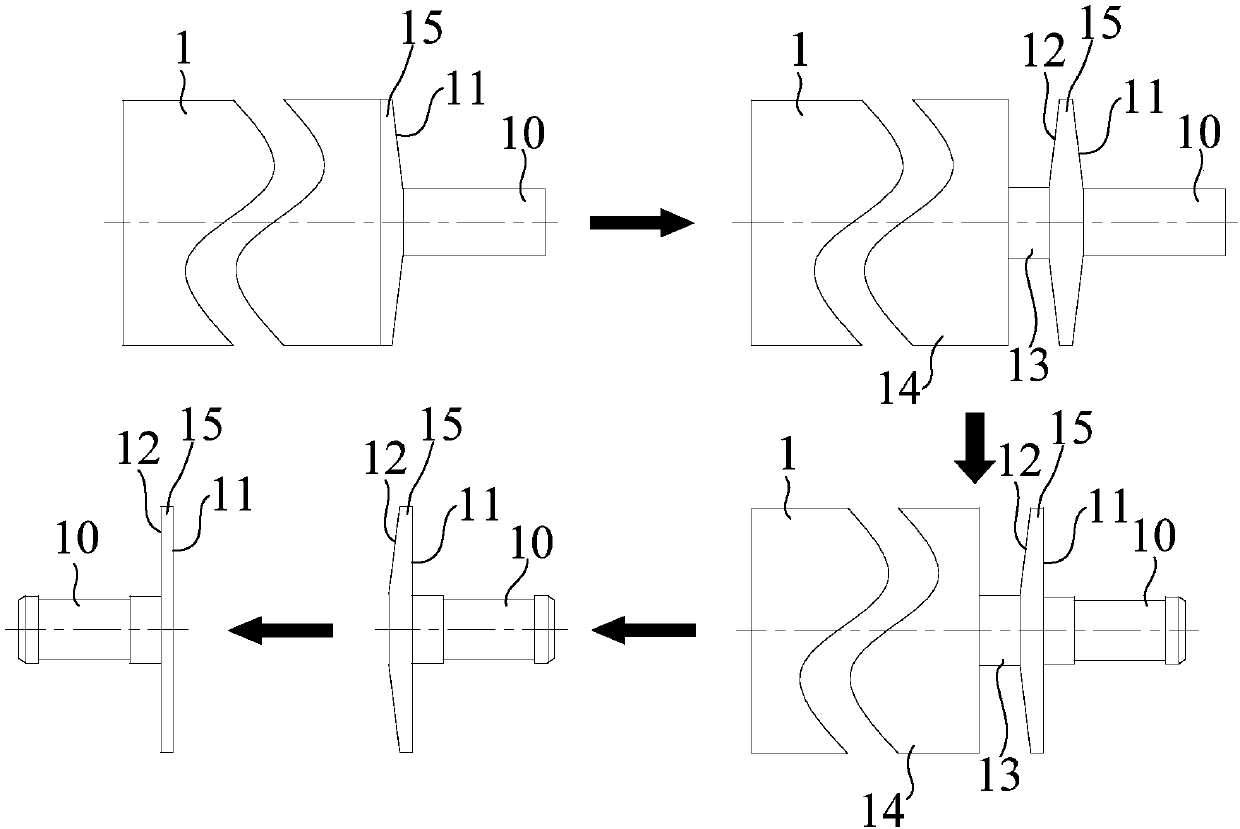

Machining method of nozzle sleeve mounting side

The invention discloses a machining method of a nozzle sleeve mounting side. The method comprises the steps that a cylinder of a nozzle sleeve and a first end face, correspondingly located on the sameside with the cylinder, on the mounting side are roughly turned and formed on a bar, wherein the first end face is a ladder-shaped face gradually thickening from the periphery of the bar to the center; a second end face, on the opposite side of the cylinder, on the mounting side is roughly turned and formed on the bar, the second end face is a ladder-shaped face gradually thickening from the periphery of the bar to the center, and the center of the second end face is connected with a body part of the bar through a connecting part; the connecting part is cut off from the central position of the second end face, and therefore the second end face and the connecting part are separated. The first end face and the second end face on the two sides of the nozzle sleeve mounting side are roughly turned and machined into the ladder-shaped faces, the thickness of the mounting side is gradually increased from the periphery to the center, rigidity of the mounting side is increased, in the cutting-off process, the precision of the mounting side is not affected, deformation of the mounting side in the machining process is reduced, and the yield of the nozzle sleeve is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Preparation method for PH-nano steel and iron corrosion inhibitor

The invention provides a preparation method for a PH-nano steel and iron corrosion inhibitor, which includes the following steps: (1) palm wax and sodium hydroxide are respectively prepared; the mixture of absolute ethyl alcohol and deionized water is prepared; first deionized water is then prepared; (2) the prepared palm wax is heated to melt until the palm wax is clear, and the liquid palm wax is poured into a first three-neck bottle; (3) the prepared sodium hydroxide is poured into the first deionized water until the sodium hydroxide is completely dissolved, and is then poured into the first three-neck bottle loaded with the liquid palm wax, and finally, the prepared mixture of absolute ethyl alcohol and deionized water is completely poured into the first three-neck bottle. The product prepared by the method has stable properties, good physicochemical properties and long anticorrosion time, and can resist high temperature, coating is thin, guns and cannons do not need to be cleaned before being used, and the product does not have adverse effects on the performance of the guns and the cannons after shooting.

Owner:长沙艾格防护新材料技术研发有限公司

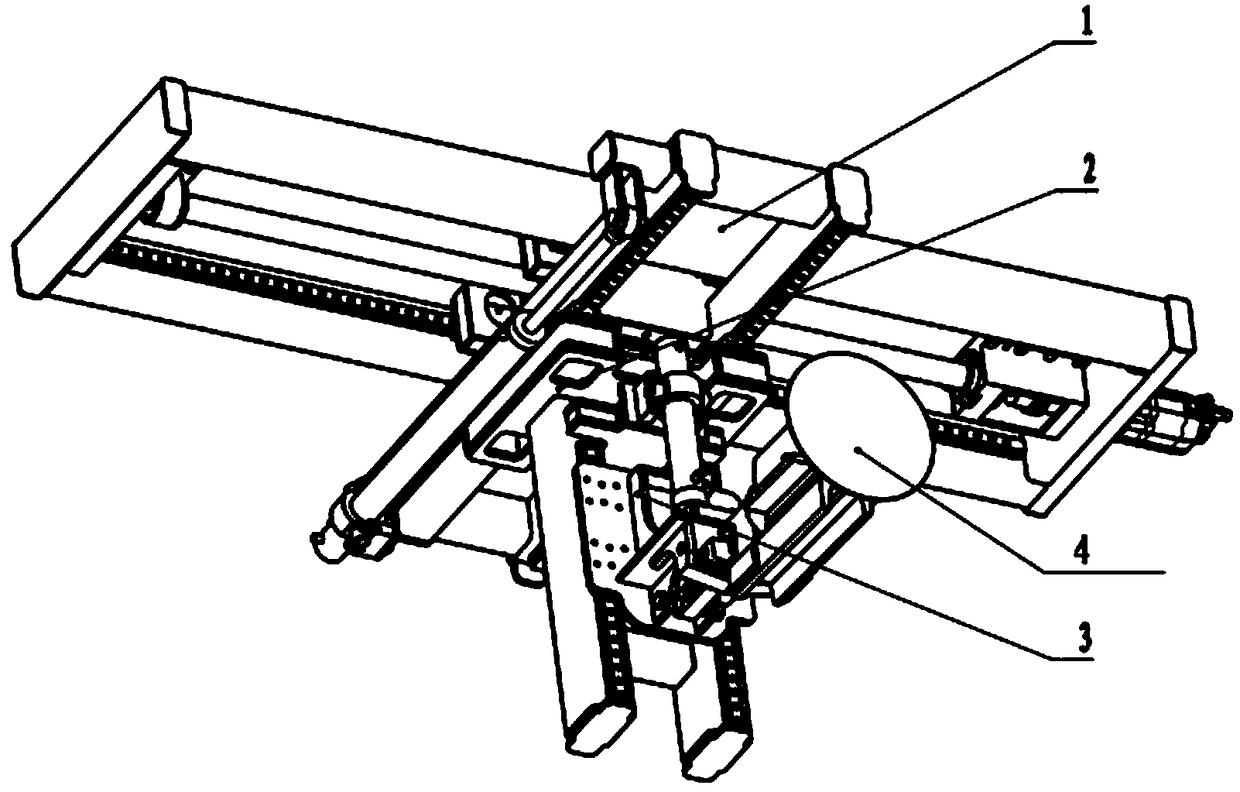

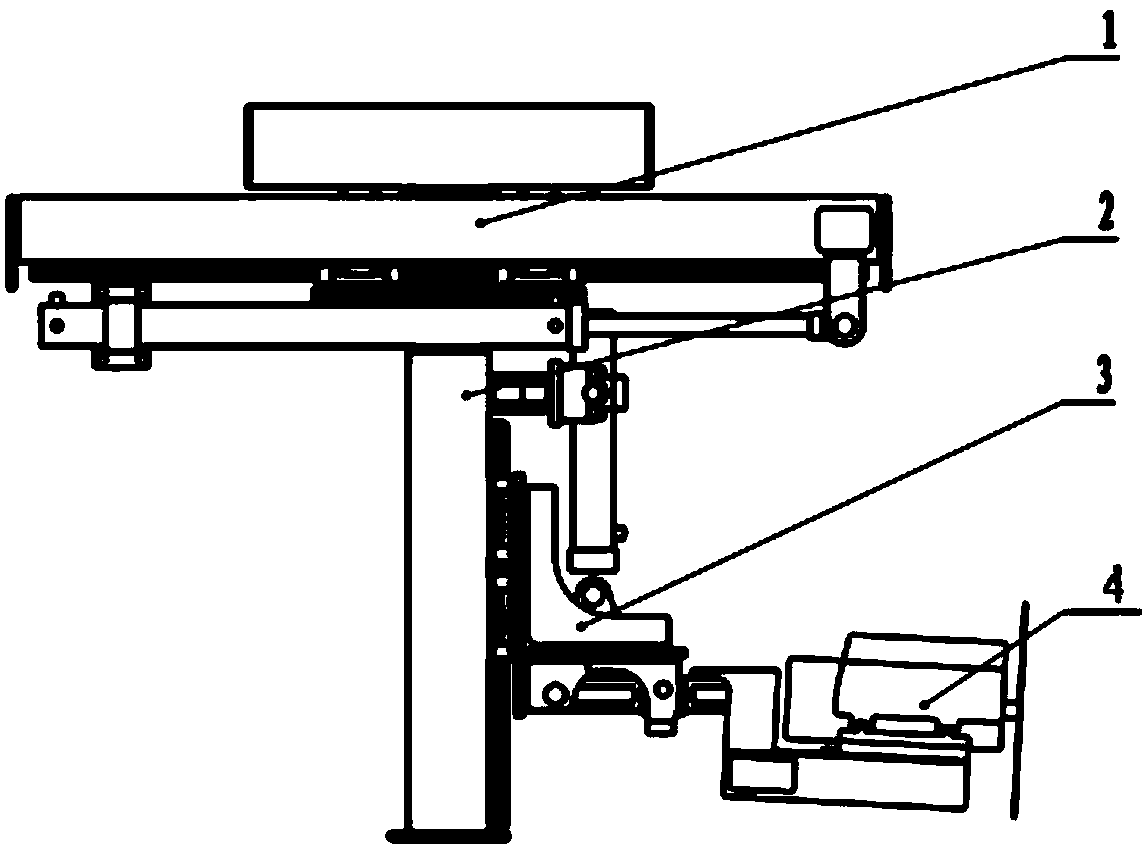

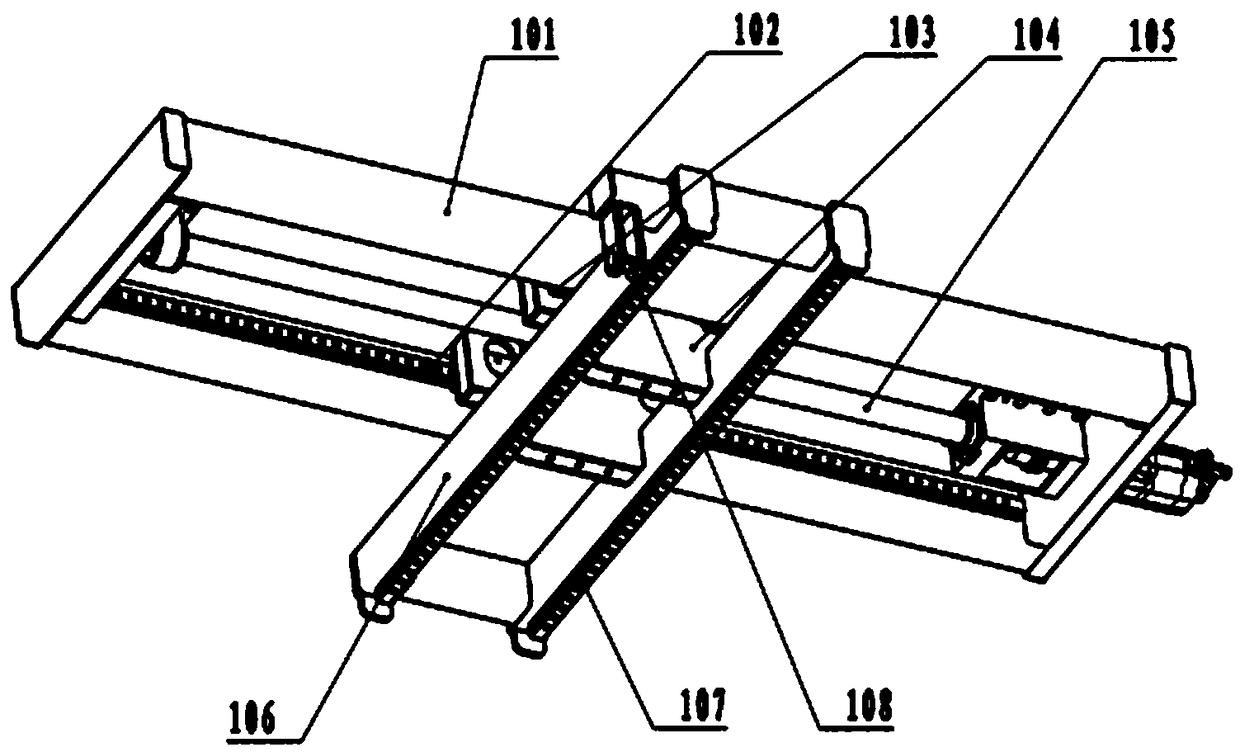

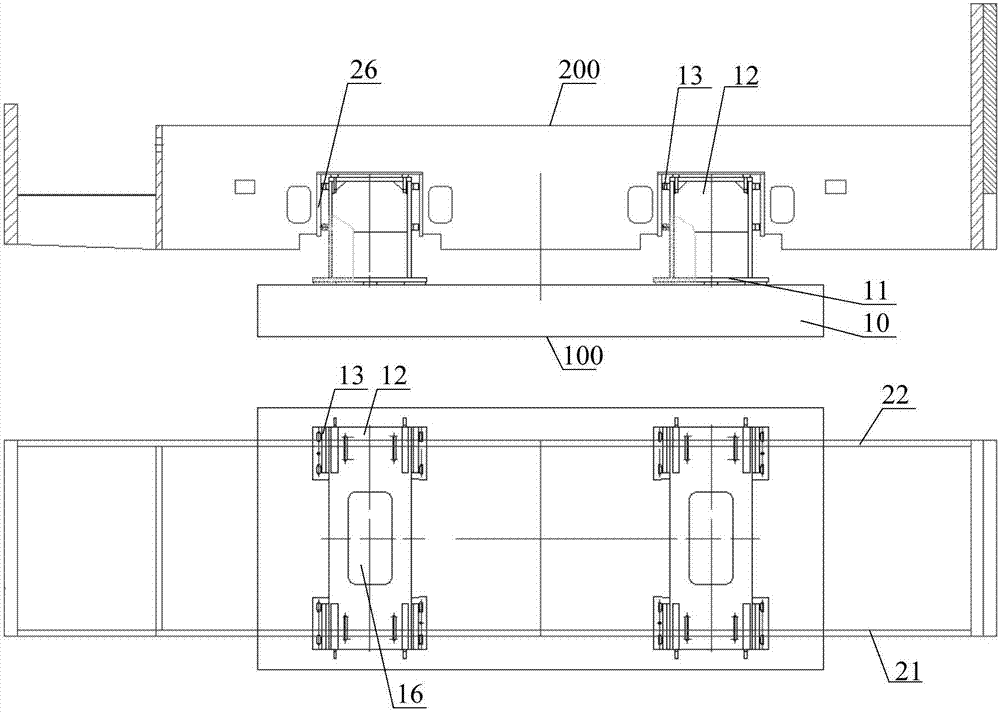

Steel rail welding recovery vehicle and rail saw moving device thereof

PendingCN109079501AReliable supportHigh degree of automationMetal sawing accessoriesOther manufacturing equipments/toolsThree degrees of freedomMovement control

The invention discloses a rail saw moving device. The rail saw moving device comprises a floating connection device and a movement control device. The floating connection device comprises a base bodyand a connecting rod used for being fixedly connected with a rail saw, the base body comprises a supporting base used for supporting the bottom of the connecting rod, one end of the connecting rod isrotatably connected to the base body, and the connecting rod and the base body rotate relative to each other within three degrees of freedom; the movement control device is used for driving the floating connection device to move vertically and horizontally and connected to the floating connection device. The movement control device of the moving device can drive the floating connection device to move, the floating connection device can reliably support the rail saw, and after the rail saw moves to the position where a steel rail is located, the specific position of the rail saw with respect tothe steel rail can also be flexibly adjusted, so that the automation degree of transporting the rail saw is increased. The invention also discloses a steel rail welding recovery vehicle comprising the rail saw moving device, and the automation degree of transportation of the rail saw can be increased.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Electronic clinical thermometer

InactiveCN100456005CPrevents drop in measurement accuracyAccuracy has no effectThermometers using electric/magnetic elementsBody temperature measurementMeasurement deviceControl circuit

An electronic clinical thermometer includes a control circuit (4) which controls operation timing according to the operations of a measurement device (3) and a notification device (9) so that the measurement operation and the notification operation will not be performed simultaneously, thereby preventing lowering of the measurement accuracy due to battery voltage lowering. The electronic clinical thermometer (1) includes the measurement device (3) for measuring a body temperature, a drive device (8) for recording the notification data, the notification device (9) for performing notification by a drive signal formed according to the notification data, and the control circuit (4) for controlling the measurement operation and the notification operation. The control circuit (4) performs control so that the operation timing of the measurement device (3) is shifted from the operation timing of the notification device (9) according to their operation states so as to prevent simultaneous operations of the measurement and notification. Thus, in the electronic clinical thermometer performing notification operation, it is possible to prevent simultaneous execution of the measurement operation and notification operation, which in turn prevents measurement accuracy lowering due to battery voltage lowering.

Owner:CITIZEN WATCH CO LTD

Preparation method of ph-nanometer iron and steel corrosion inhibitor

ActiveCN104894567BSolving the Difficulty of CorrosionImprove performanceSodium hydroxideMaterials science

The present invention provides a kind of preparation method of PH-nanometer iron and steel corrosion inhibitor, comprises the following steps: (1) prepare palm wax, sodium hydroxide respectively; Prepare the mixed solution of dehydrated alcohol and deionized water; Prepare the second One part of deionized water; (2) heat and melt the prepared palm wax until clear, and pour it into the first three-neck bottle; (3) pour the prepared sodium hydroxide into the first part of deionized water until dissolved Completely, then pour into the first three-necked bottle equipped with liquid palm wax, and finally pour the mixed solution of absolute ethanol and deionized water into the first three-necked bottle. The product prepared by the method has stable performance, good physical and chemical properties, long anti-corrosion time, high temperature resistance, thin coating film, guns and cannons do not need to be cleaned before use, and have no adverse effect on the performance of the guns and cannons after shooting.

Owner:长沙艾格防护新材料技术研发有限公司

Device for producing elevator shaft information

A device for producing information related to a position of an elevator car in an elevator shaft includes a toothed belt having a plurality of teeth spaced along a length of the belt and mounted in an elevator shaft, an encoder mounted on the elevator car and having a toothed wheel for engaging the teeth, and guide rollers mounted on the elevator car and engaging the toothed belt to urge the plurality of teeth into engagement with the toothed wheel.

Owner:INVENTIO AG

Device for drilling centre hole of bar materials for lathe

InactiveCN102672234AGood precisionAccuracy is goodAttachable boring/drilling devicesMachine toolBiomedical engineering

The invention discloses a device for drilling a centre hole of bar materials for a lathe. The device comprises a clamping device and a hole drilling device, the clamping device is arranged at the front end of the hole drilling device, and the device is characterized by further comprising a fixed device which is arranged at the back end of the hole drilling device. The device has the advantages that the problems that a centre bit is easy to damage when the center hole is drilled on a common lathe by using a common method through the bar material hole drilling device and lathe accuracy is greatly influenced due to centre frame vibration due to bar material jumping are overcome. The centre hole drilled by the device is good in accuracy, the bar materials do not rotate, and the lathe accuracy is not influenced.

Owner:成都亨通光通信有限公司

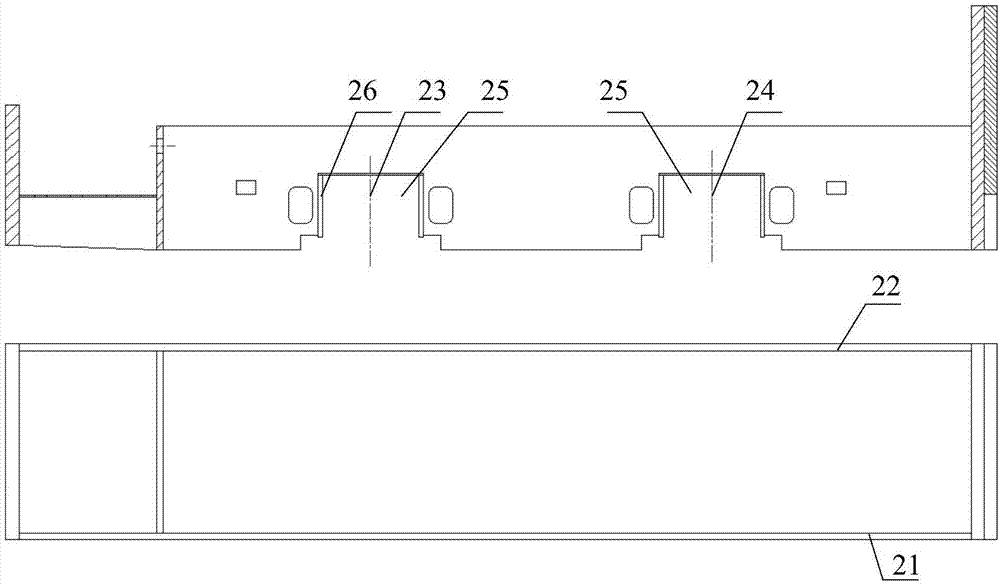

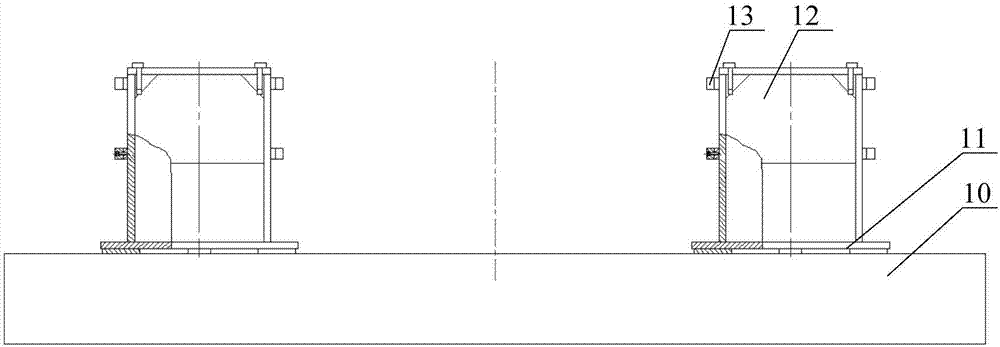

Assembling tool for industrial-mineral electric locomotive axle housing square holes

PendingCN107877049AMeet group requirementsGuaranteed pairing accuracyWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention provides an assembling tool for industrial-mineral electric locomotive axle housing square holes. The assembling tool is used for assembling a locomotive frame of an industrial-mineral electric locomotive. The locomotive frame includes a left side plate and a right side plate which are relatively arranged to one another. A front shaft and a rear shaft corresponding to the left side plate and the right side plate are separately provided with two axle housing square holes. The assembling tool includes a tooling platform below the electric locomotive frame and two positioning assemblies which are detachably installed on the top surface of the tooling platform. The two positioning assemblies are correspondingly arranged in the axle housing square holes of the front shaft and therear shaft. Each positioning assembly includes a clamping block which can be enclosed into the axle housing square holes and a plurality of adjustment blocks which are detachably installed on the clamping block. The adjusting blocks are mounted on one side, facing the literal edge of the axle housing square holes, of the clamping block. A clearance for positioning a vertical plate of an axle housing is formed between the positioning assemblies and the corresponding axle housing square holes. The assembling tool for industrial-mineral electric locomotive axle housing square holes has high accuracy.

Owner:CNR LANZHOU LOCOMOTIVE

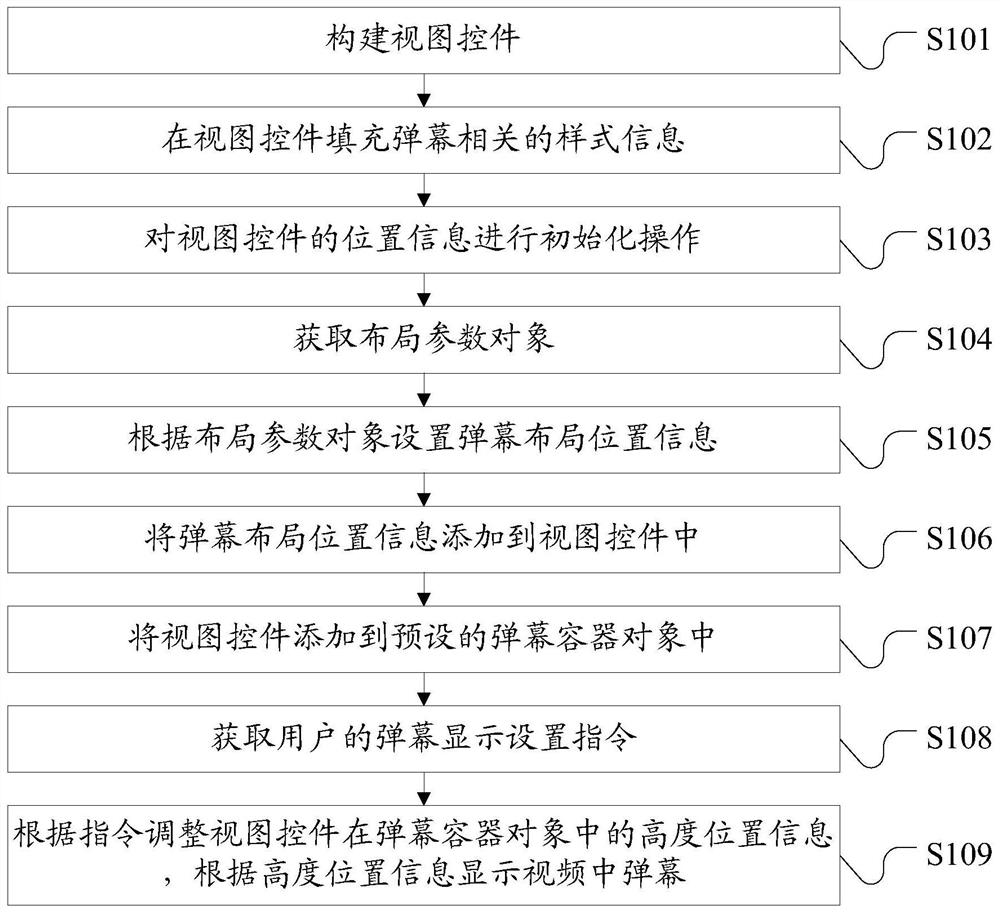

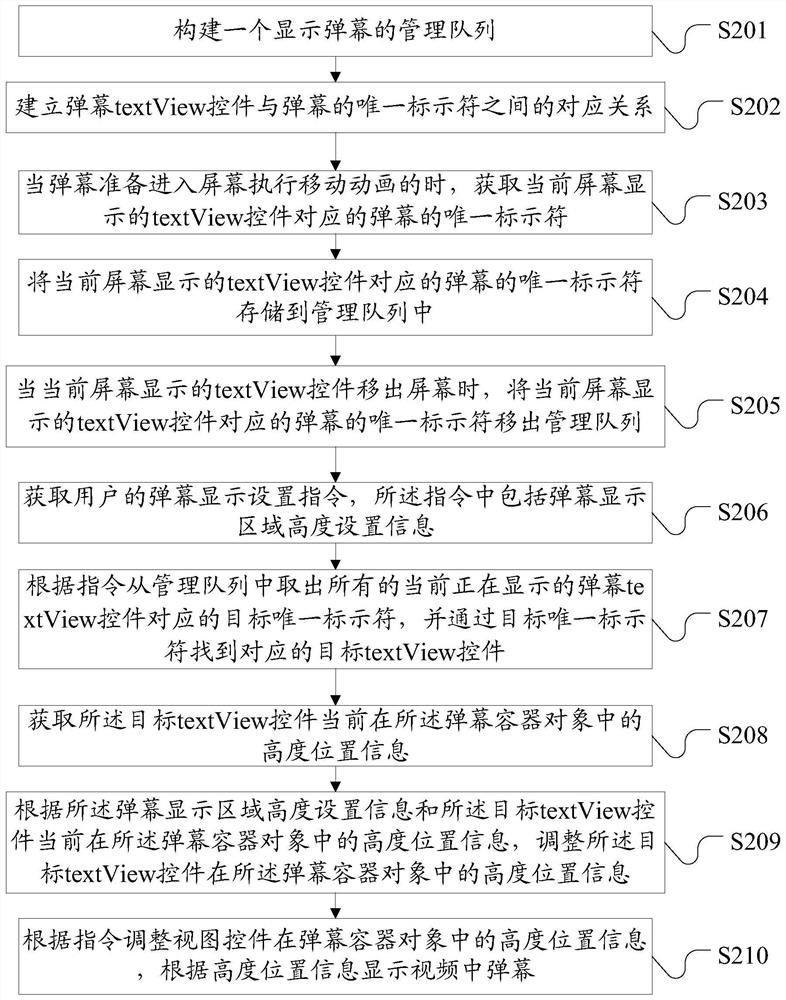

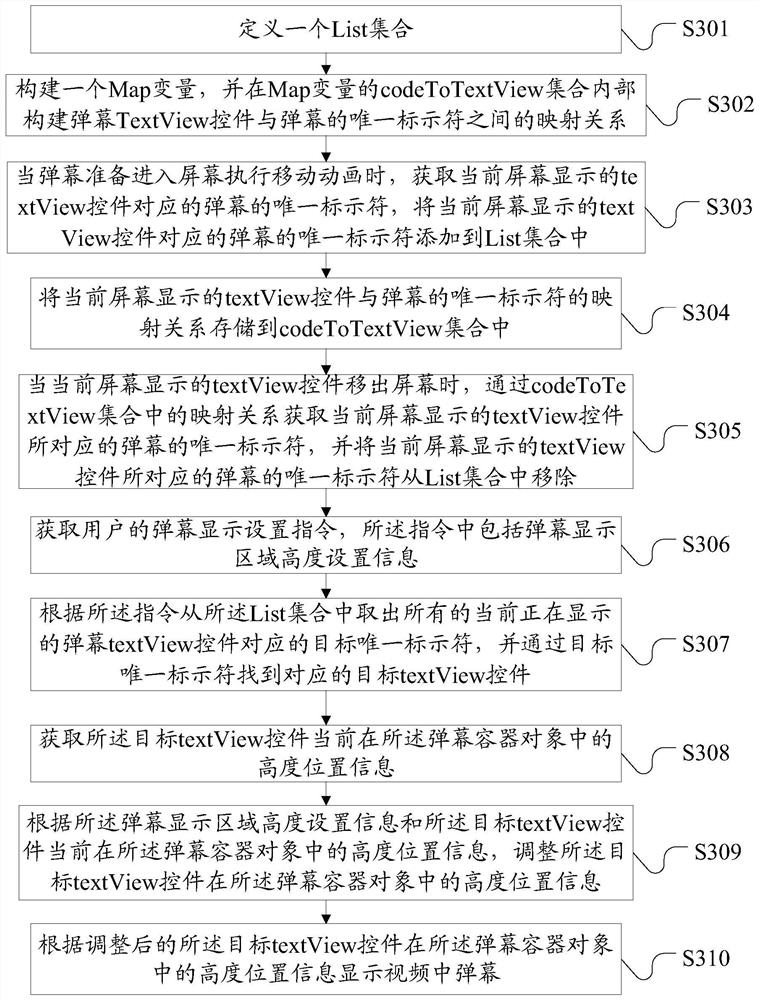

A barrage display method, device and electronic equipment

ActiveCN110881145BGuaranteed accuracyAccuracy has no effectSelective content distributionComputer graphics (images)Unique identifier

Owner:WUHAN DOUYU NETWORK TECH CO LTD

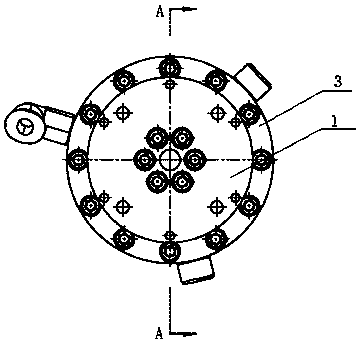

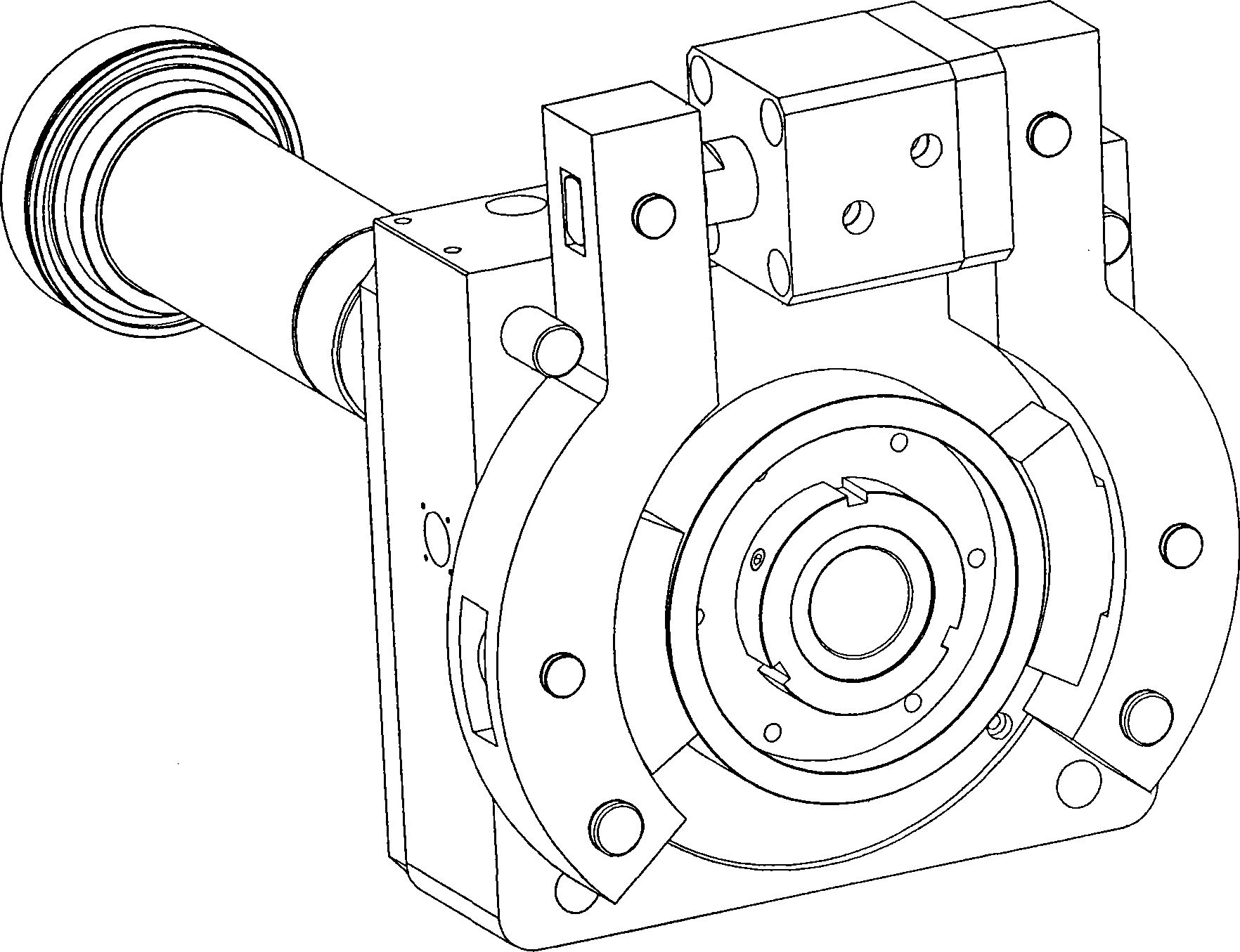

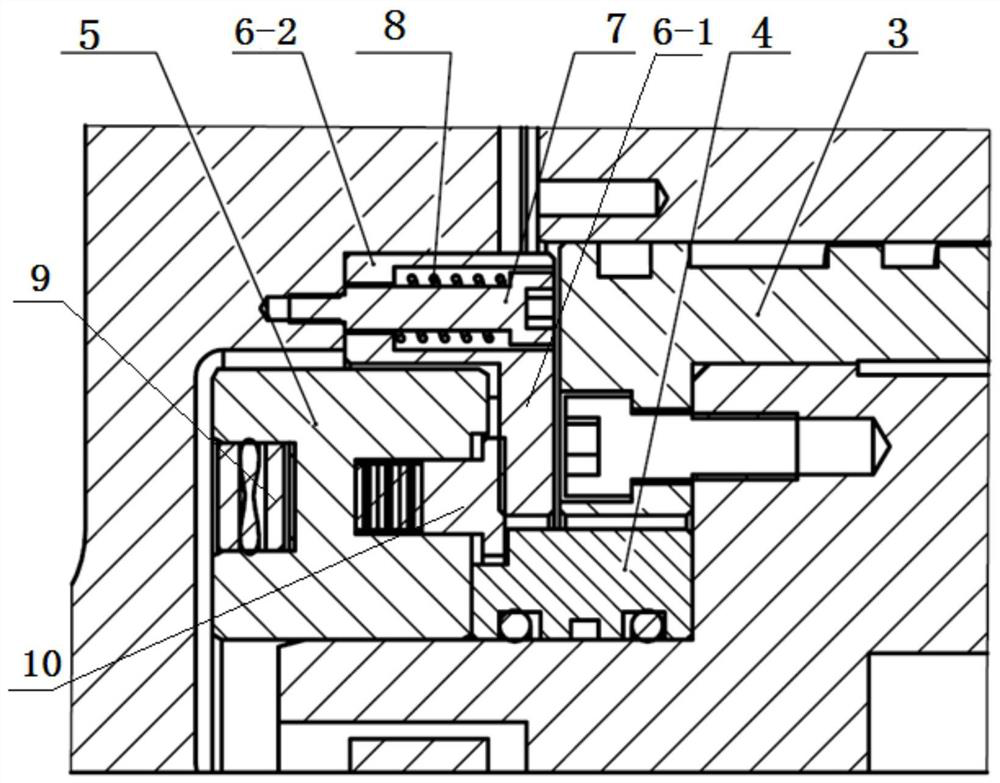

Floating type numerical control rotary table safety locking structure

PendingCN111702511AAccuracy has no effectFast brakingLarge fixed membersHydraulic cylinderNumerical control

The invention discloses a floating type numerical control rotary table safety locking structure. The floating type numerical control rotary table safety locking structure comprises a rotary table basebody and a rotary motion body, wherein a brake sleeve, an annular sleeve and a fixed seat are fixed to the rotary table base body in a sleeving manner; a locking ring which is in synchronous rotationalong with the rotary motion body is connected to the inner part of the rotary motion body; connecting bolts which are used for connecting the locking ring and the rotoary motion body are uniformly distributed on the locking ring; the locking ring can move in the axial direction of the connecting bolts; a reset spring which is used for applying force onto the locking ring to enable the locking ring to be propped against the rotary motion body is arranged on each connecting bolt in a sleeving manner; releasing oil cylinders are uniformly distributed on the fixed seat; a brake boot is fixed toa piston rod of each releasing oil cylinder; the releasing oil cylinders are monoactuated hydraulic cylinders; the compression springs are arranged in the front of the brake boots and the fixed seat,and can apply force to the brake boots in the direction facing the locking ring; and the brake boots can push the locking rings to move towards one side of the brake sleeve and is used for compactingthe locking ring on the brake sleeve.

Owner:宝鸡忠诚机床股份有限公司

A high-precision arch dam deformation monitoring equipment and measurement method

ActiveCN107014304BEliminate deformation disturbanceGuaranteed accuracyUsing optical meansStress relievingDeformation monitoring

A piece of high-precision dam deformation monitoring equipment and a measuring method belong to the field of measuring and monitoring. The equipment comprises a plurality of monitoring units. Each monitoring unit comprises an indium steel pipe system, and a transmitting device, a refracting device and a receiving device which cooperate with one another and are arranged along an optical path. Each indium steel pipe system comprises two indium steel pipes and length measurement position-sensitive sensors in one-to-one correspondence with the indium steel pipes, wherein the indium steel pipes are fixed at one measuring point of a measuring section, and the corresponding length measurement position-sensitive sensors are fixed at the other measuring point of the measuring section, and the corresponding indium steel pipes are connected through a moving pair with the measuring point at which the corresponding length measurement position-sensitive sensors are fixed. Through a plurality of monitoring units arranged in a triangular shape, dam deformation data is monitored and acquired from all measuring sections. The indium steel pipes of each indium steel pipe system are fixed at one measuring point, and the other measuring point is connected with the indium steel pipes through a moving pair. The noncontact mode of measurement and the stress-free mode of connection can eliminate deformation disturbance of the indium steel pipes caused by stress and ensure the accuracy of measurement.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com