PCB bell mouth manufacturing method

A manufacturing method and tapered hole technology, which can be used in printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as untimely, and achieve the effects of improving efficiency, reducing costs, and high quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A method for manufacturing a tapered hole in a PCB, comprising the following steps:

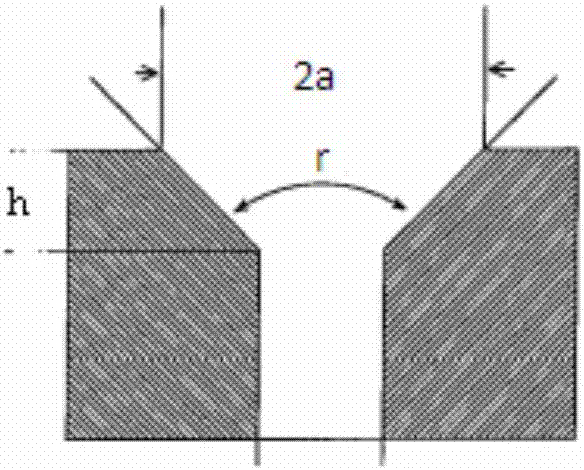

[0020] (1) Select the tapered drill bit according to the size of the tapered hole, which is 0.4mm larger than the diameter of the drilled hole;

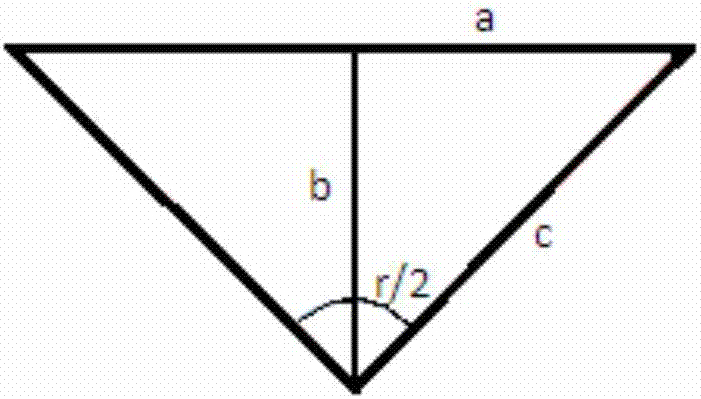

[0021] (2) Calculate the drilling depth according to the customer's requirements for the diameter of the tapered hole and write the result into the tapered hole drilling program; a is the radius of the tapered hole, b is the drilling depth of the drill bit, r / 2 is one-half of the drill point angle;

[0022] (3) Work in the order of the conventional drilling process: a. Install the backing board→b. Kind of pins→c. Put on the backing board→d. Put on the board to be drilled→e. "Mushroom head" presses the aluminum sheet → g. Then cover the cold stamping plate and stick it firmly with adhesive tape;

[0023] (4) Use a multimeter to confirm that the aluminum sheet and the machine table are conductive, and ensure that the only connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com