Device for measuring thermal conductivity of film with steady-state method

A technology of thermal conductivity and steady-state method, which is applied in the field of devices for measuring thermal conductivity of thin films by steady-state method, to achieve the effects of avoiding thermal radiation, simple principle and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the present embodiment, the testing method of testing the thermal conductivity of carbon nano film is as follows:

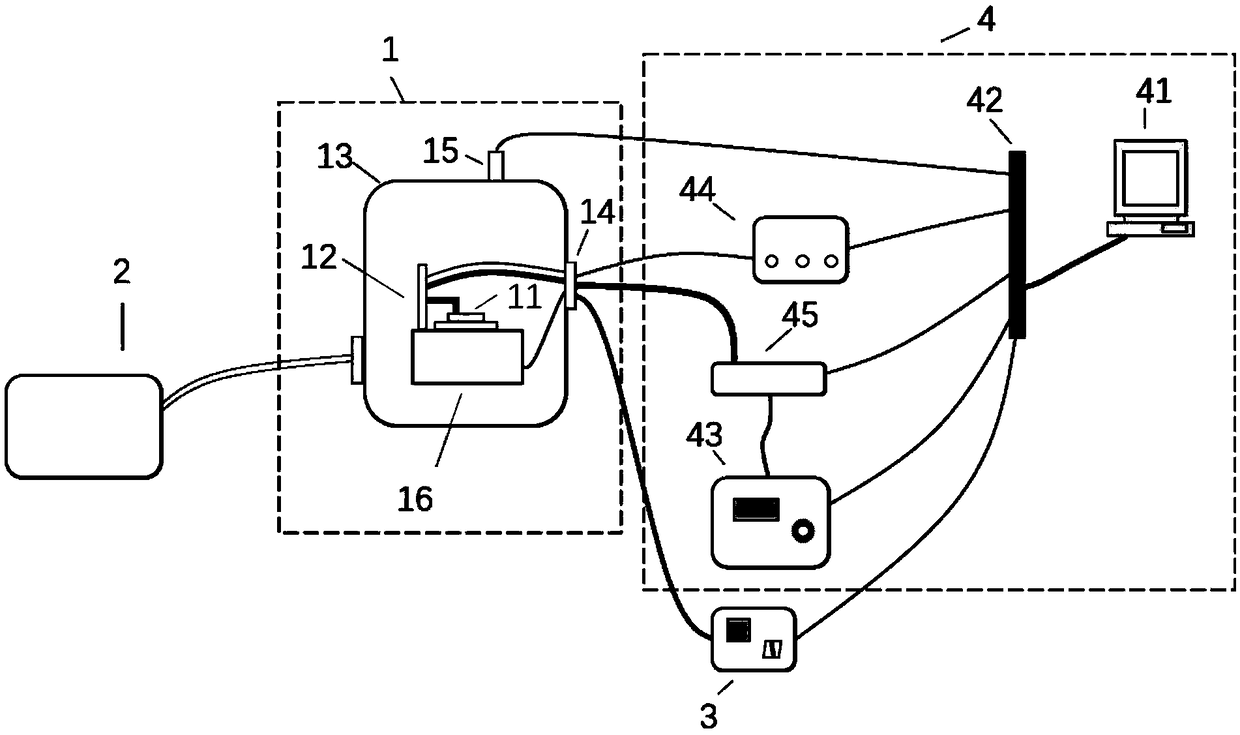

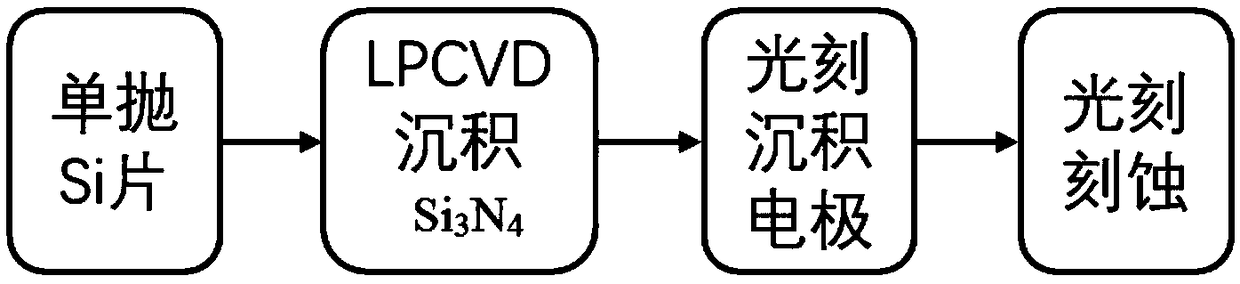

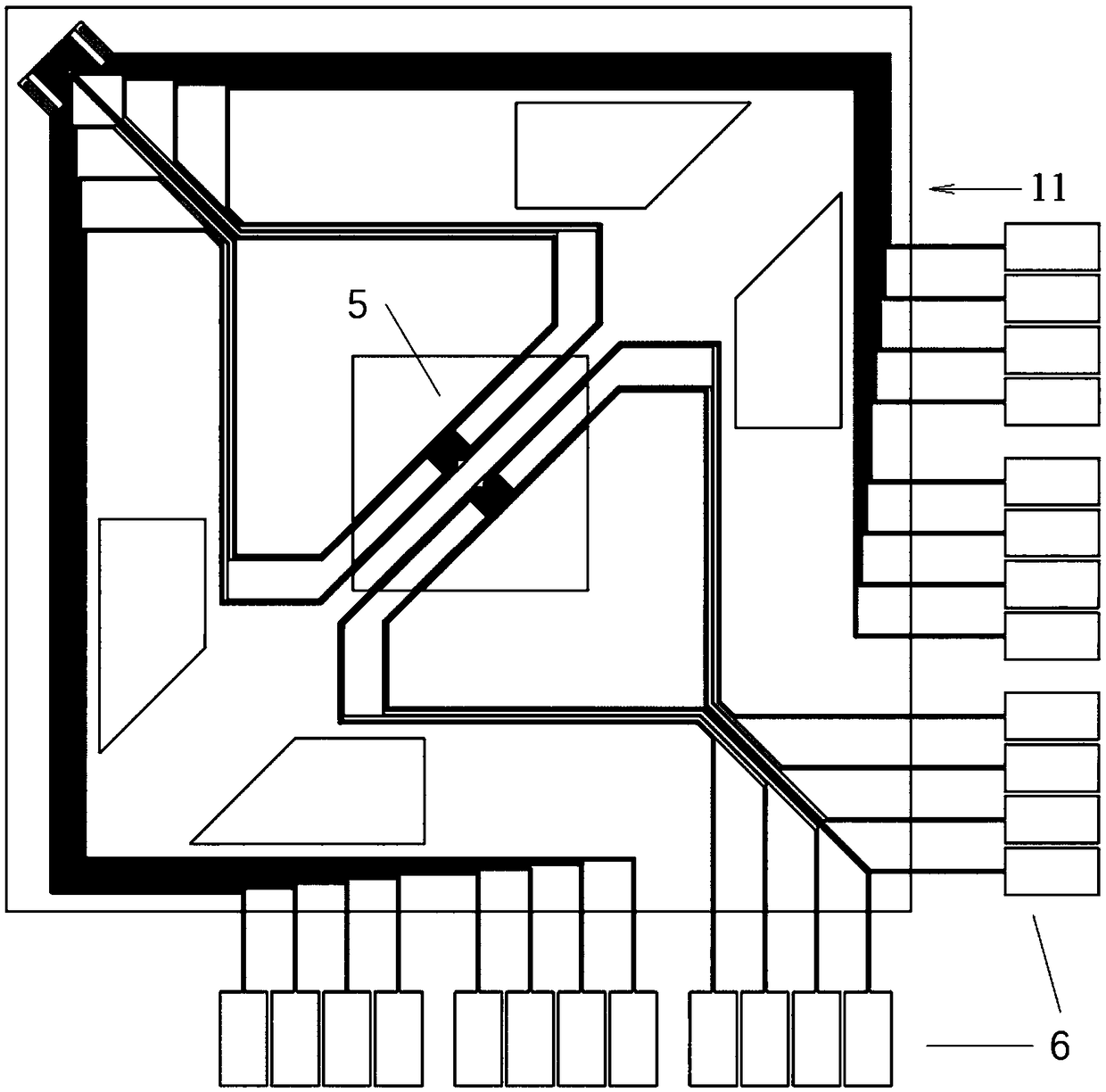

[0039] Such as Figure 1-Figure 2 As shown, the manufacturing process of the test chip 11 includes: single polishing Si wafer → LPCVD deposition of Si 3 N 4 → Photolithographic deposition of electrodes → photolithographic etching, the size of the photolithographic plate can be modified according to the size of the sample, and then test chips of different sizes can be obtained. Such as image 3 As shown, the central part of the test chip 11 is the sample-carrying area 5 , and the circuit connection area 6 is set on the outside of the test chip 11 . After fabricating the test chip 11 with an electrode spacing of 100 μm, the sample to be tested is transferred to the sample-carrying area 5 on the test chip 11 . Afterwards, the test chip 11 is placed on the sample stage 12 , and the circuit of the test chip 11 is connected to the sample stage 12 at the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com