Device for laying a cover

A cover and supply station technology, applied in book binding, transportation, packaging, printing, etc., to achieve the effect of minimizing the time for assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

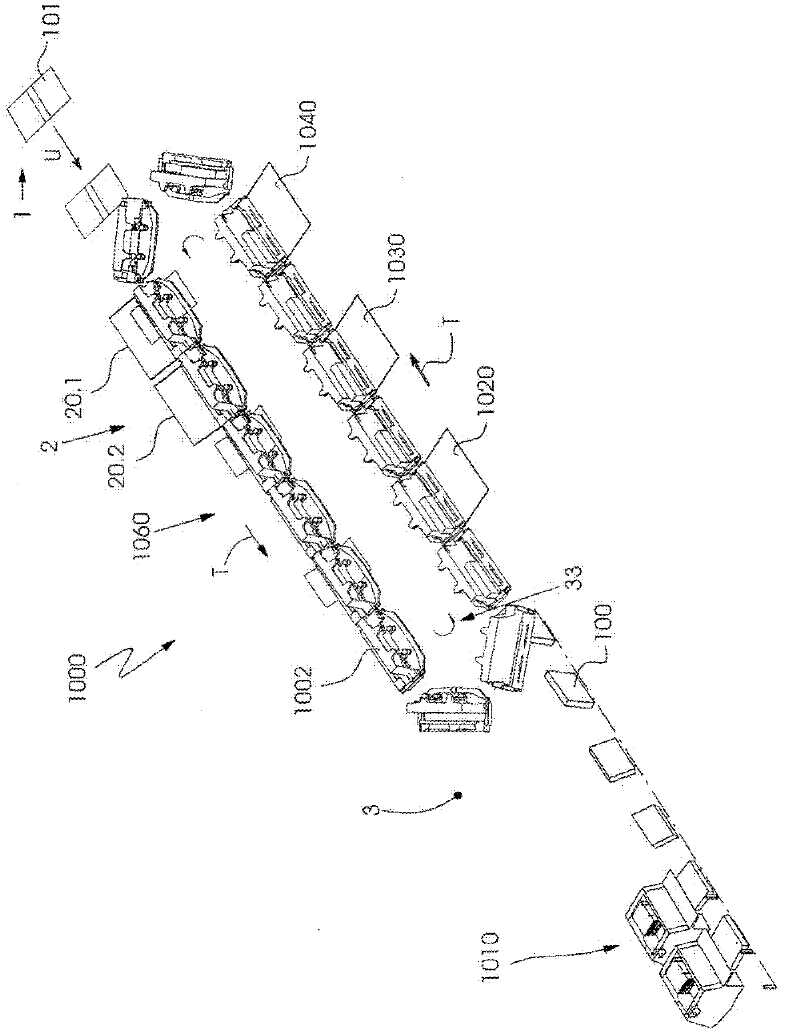

[0025] figure 1 A detail of the perfect binding machine 1000 is shown together with a part of the associated book block transport system 33 , which is formed by a driven revolving chain (not shown in detail) with clamps 1002 fastened thereto. The drive of the slewing chain is formed, for example, by a servomotor (not shown). Book blocks 100 come from a collating machine 1010 and are fed to the perfect binding machine 1000 in a transport direction T. The book block 100 is gripped by grippers 1002 and conveyed to a first processing station, the book-back processing station 1020 . The back processing station 1020 can have a plurality of processing tools not shown. The back-treated book block 100 is further transported to the gluing station 1030 and provided with adhesive material. Shielding can optionally be applied in a subsequent shielding station 1040 In the device 20.1 for laying and fixing covers, the covers 101 supplied by the cover supply station 1 are laid and fasten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com