Machining method of nozzle sleeve mounting side

A processing method and nozzle technology, applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve problems such as easy deformation of the installation edge, and achieve the effects of improving the pass rate, reducing deformation, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

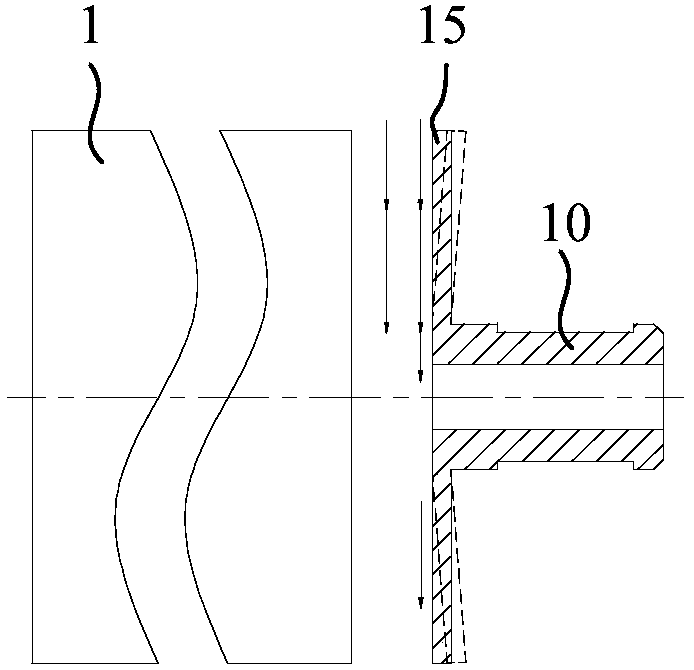

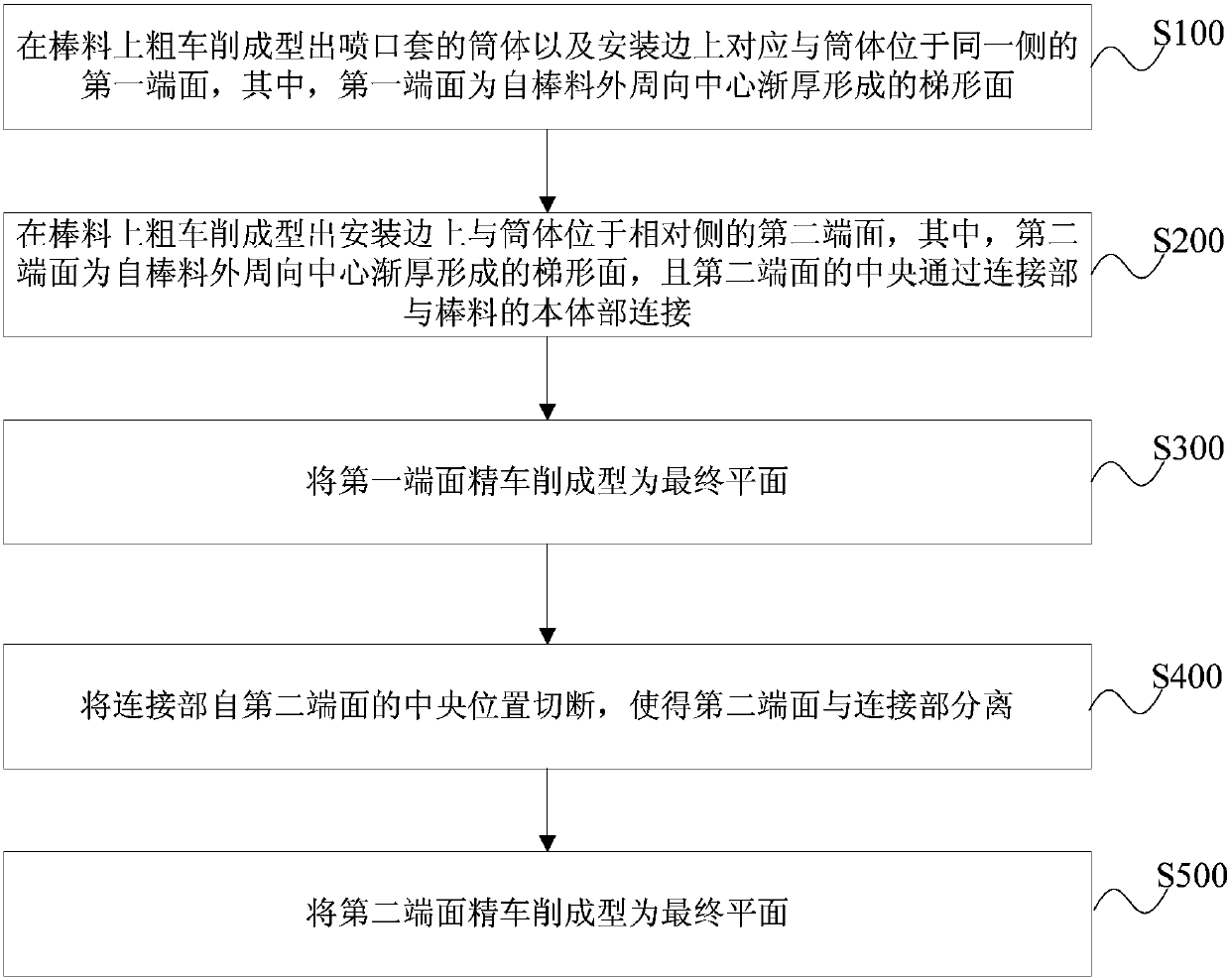

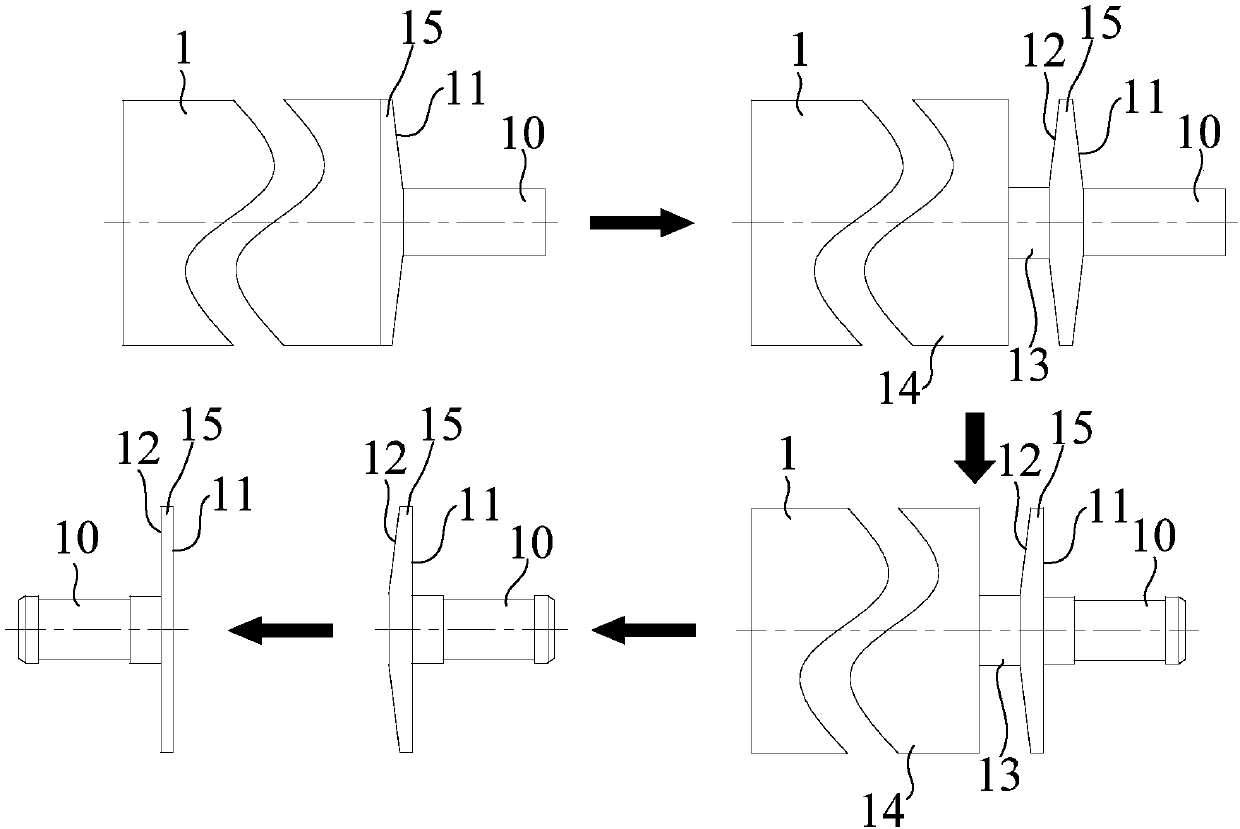

[0032] refer to figure 2 and image 3 , a preferred embodiment of the present invention provides a method for processing the mounting edge of the spout sleeve, comprising the following steps:

[0033] Step S100, the first end surface 11 corresponding to the same side as the cylinder body 10 on the cylinder body 10 and the installation edge 15 of the bar stock 1 formed by rough turning, wherein the first end surface 11 is from the outer circumference direction of the bar stock 1 Trapezoidal face formed by gradually thickening center.

[0034] Step S200, rough turning on the bar 1 to form a second end surface 12 on the side opposite to the barrel 10 on the mounting edge 15, wherein the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com