Assembling tool for industrial-mineral electric locomotive axle housing square holes

A technology for electric locomotives and axle boxes, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low alignment accuracy, achieve the effects of ensuring stability and accuracy, wide application range, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

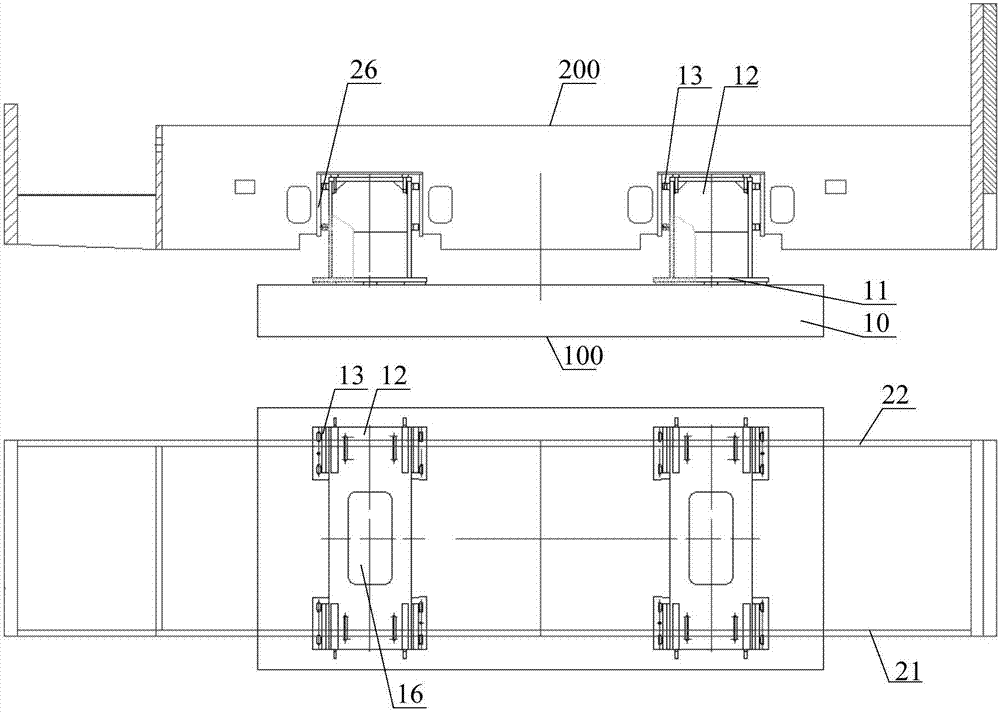

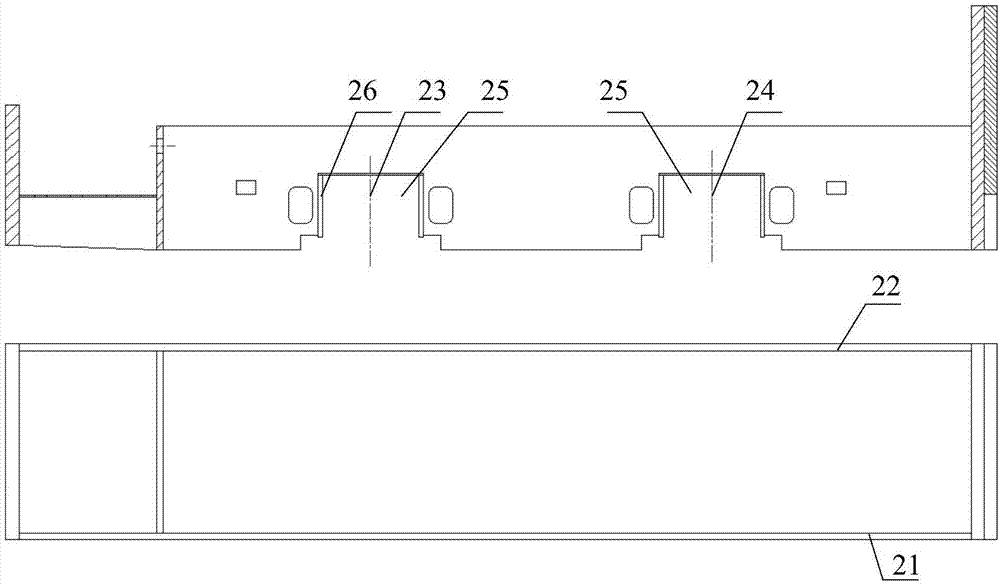

[0048] figure 1 The front view and top view of the assembly tooling for the square hole of the axle box of industrial and mining motors provided by the embodiment of the present invention, figure 2 For the front view and top view of the frame of the industrial and mining electric locomotive provided by the embodiment of the present invention, refer to figure 1 and figure 2 As shown, the assembly tooling for the square hole of the axle box of the industrial and mining electric locomotive provided by the present invention is used to assemble the vehicle frame 200 of the industrial and mining electric locomotive. Two axle box square holes 25 are respectively arranged on the corresponding front axle 23 and rear axle 24 on the right side plate 22,

[0049] The tooling assembly 100 includes: a tooling platform 10 located below the vehicle frame 200 and two detachable positioning assemblies 11 installed on the top surface of the tooling platform 20, and the two positioning assembli...

Embodiment 2

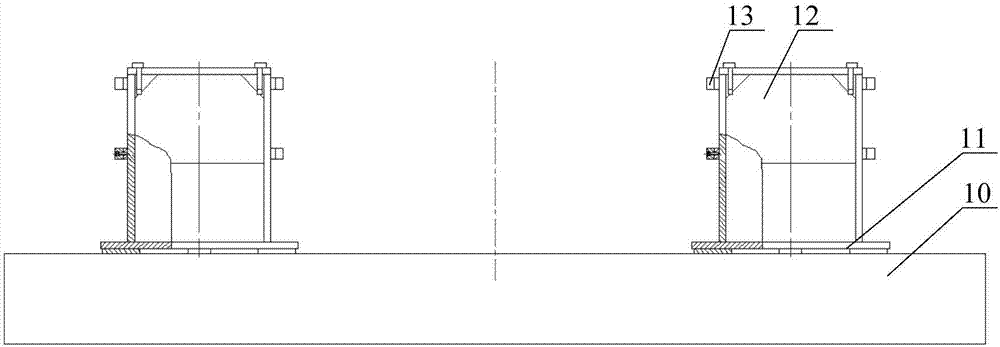

[0056] image 3 The schematic diagram of the structure of the assembly tooling for the square hole of the industrial and mining motor axle box provided by the embodiment of the present invention, refer to figure 1 , figure 2 and image 3 As shown, the height of the block 12 is greater than the height of the square hole 25 of the axle box, and the size of the block 12 along the length of the vehicle body is smaller than the width of the square hole 25 of the axle box.

[0057] Specifically, the height of the clamping block 12 is greater than the height of the axle box square hole 25, so as to ensure that when the vehicle frame 200 is hoisted and placed on the assembly tooling 100, the vehicle frame 200 is supported by the positioning assembly 11 in the axle box square hole 25, The bottom edge of the vehicle frame 200 will not touch the tooling platform 10, that is, the size of the assembly is only affected by the size of the axle box square hole 25 itself, and will not be di...

Embodiment 3

[0063] Figure 4 For the structural schematic diagram of the connecting part of the adjusting block and the clamping block of the assembly tooling provided by the embodiment of the present invention, refer to figure 1 and Figure 4 As shown, the clamping block 12 is provided with a protruding block 14 corresponding to the position of the adjusting block 13 , and the adjusting block 13 and the protruding block 14 are connected by an inner bolt 15 . Specifically, the protruding block 14 is welded on the clamping block 12 , and the protruding block 14 and the adjusting block 13 are correspondingly provided with holes for installing the inner bolt 15 .

[0064] On the basis of the above-mentioned embodiments, this embodiment is provided with a bump 14 on the block 12, and the adjustment block 13 is connected to the block 12 through the bump 14, compared to directly connecting the adjustment block 13 to the block 12 The method is simpler and easier to implement in terms of techno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com